CNC Torch Table

![]() Hint: Current work uses the Universal Axis as part of a precision motion ecocystem. See current work at D3D CNC Torch Table

Hint: Current work uses the Universal Axis as part of a precision motion ecocystem. See current work at D3D CNC Torch Table

Contents

Overview

The CNC Torch Table (aka RepTab) is an enabling machine for any workshop. This machine enables creation of custom parts for fabrication or replacement of broken components. The CNC Torch/Plasma Table development is rebooting and building on some of the later versions, but starting with the replication of Koruza's Good Enough CNC Plasma Table. One the integrated designs is to go towards gas versus plasma, because of the dependencies of a plasma cutter and other devices that have not been fully open source. As well as the availability of gas production being a valuable option. The Version 3 iteration expects to build, source, and improve designs toward a 100% open source project and parts. The power supply, height controller, torch, and plasma cutter are items needing to be developed. In progress, the need for on-demand materials and supplies can be met with a functional and accurate CNC Torch/Plasma Table that will reduce manufacturing time and increase capacity. The Koruza Project does not a have table, therefore, building on previous versions maybe a possibility.

2019 Update

- Working on CNC Torch Table Height Controller

2016 Update

During the course of 2014/2015 workshops of metal fabrication, the CNC Torch Table/Plasma Table is essential for future builds. The MicroTractor and the World's First Open Source Bulldozer can be built with general metal working toolings, however, the CNC Torch Table is a major manufacturing component of the GCVS. Tom Griffing and Jonathan Kocurek find it a useful effort to focus on the CNC Torch Table for PowerCube replications and parts manufacturing. Marcin's introduction with the Koruza project is a feasible option, however, Marcin's concerns are that some propriety parts exists that will need to be open source and developed. Such as the height controller and power supply. Tentative plans and efforts to grow the CNC Torch/Plasma Table Team are forming for 2016.

2014 Team Goals

Current team goals as of June 5 2014 for the end of June 2014.

- Have the torch cutting steel, up to 1" thick, to a tolerance of 1/16" over 10 inches on all dimensions, and within 1/16 of a straight line re the waviness of the line. It is ok if it takes some manual intervention, or hand holding.

- The machine should be reasonably durable and not finicky or prone to breakage, or absurdly high wear and tear. For example, the wiring is currently prone to breakage. Also the arduino on the z control would probably stop working pretty fast from the stuff splattering on it.

This entails meeting milestone 1 in the torch table prototype 2 requirements document (see dev board through dozuki, overall module, requirements document).

- for the short term, make sure the documentation is at the point that someone can easily step in to Anthony's role in getting things working, and to operate the table for cutting.

- record why we made the system the way we have so far, rather than some other way. This is important to avoid the need to go over the same ground too many times.

2016 Team Goals

- Using 3D Printer Construction Set instance for xyz drive.

- Off-shelf height controller tested, then replaced with open source version

- Open source version - done by a design challenge, such as heroX or simple crowd platform

Versions

Details

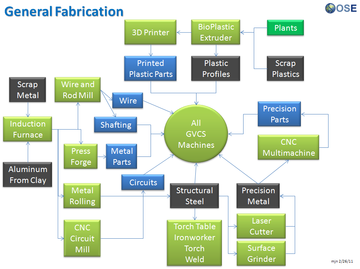

The CNC Torch Table allows workshops to create replacement parts on the fly for many of the components used in the GVCS. Additionally, the Torch Table gives workshops the ability to create many of the custom components used in the GVCS Machines. Many parts that make up the 50 GVCS Tools can be cut on the CNC Torch Table, making this machine valuable for replication.

Documentation

Much of the current documentation and raw data concerning

Product Ecology

Made with

Multimachine - Precision Guides, bearings

Multimachine - Precision Guides, bearings Ironworker

Ironworker

Creates

See Product Ecologies for more information.

See Also

- CNC Torch Table Crash Course

- Research & Development

- Bill of Materials

- Manufacturing Instructions

- User's Manual

- CNC Torch Table Github Repo

- OSE CNC Torch Table Development Google Group / Mailing List

- CNC Torch and Router Table on Dozuki