Boundary Layer Turbine

Contents

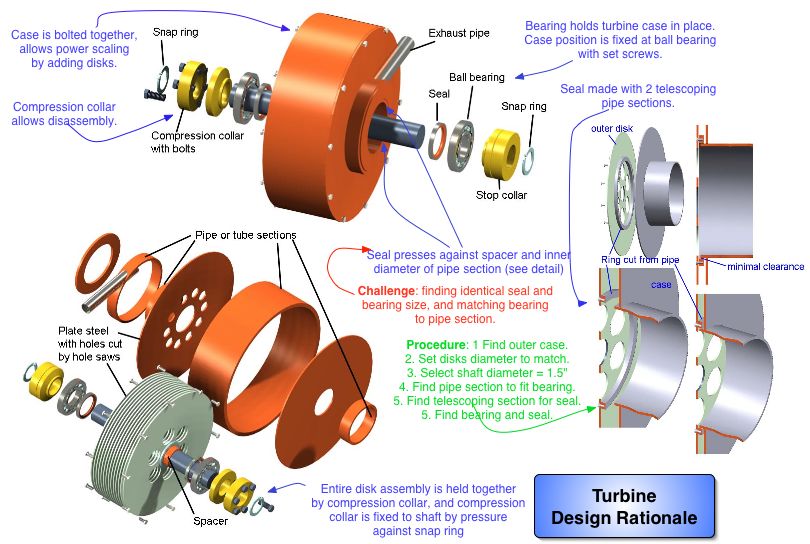

Design Rationale

Drawings by Dan Granett, Granett Engineering:

This is an external combustion engine with proven efficiencies of 25% for un-optimized models with steam (Rice, Warren, Transactions of the ASME, Journal of Engineering and Power, January 1965, pp. 28-36). A working fluid spins this turbine by means of surface friction. When the disk spacing is small (on the scale of a millimeter), energy transfer from the working fluid to the disks can be efficient. Design rationale:

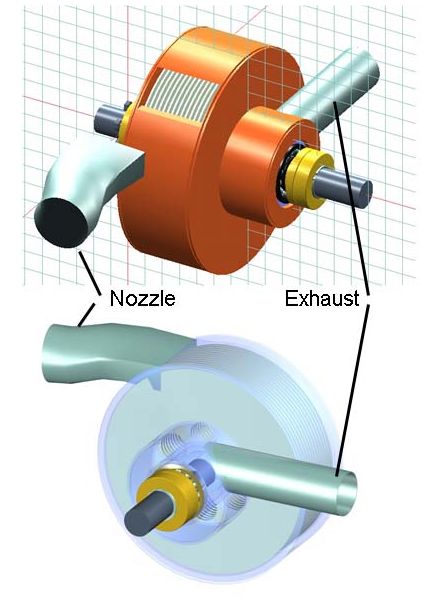

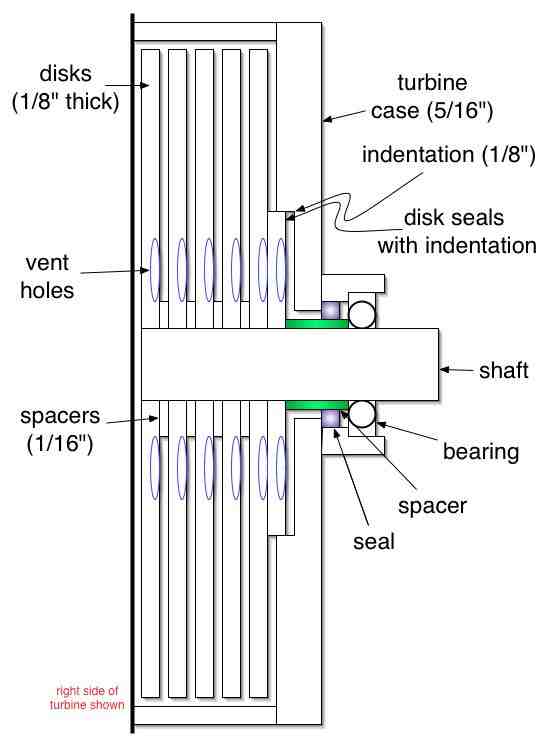

Working fluid (such as steam) enters tangentially to the disks through a nozzle:

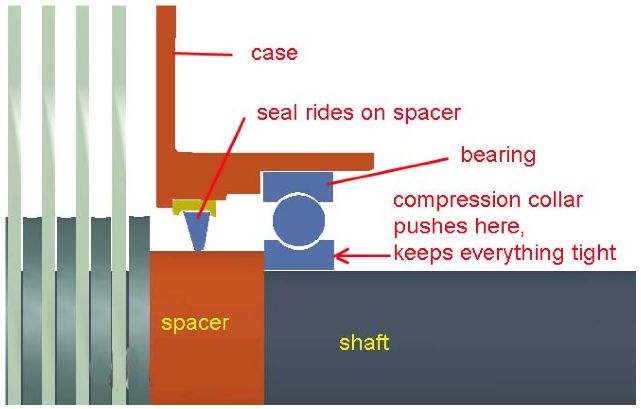

Bearings must be protected from the working fluid with a shaft seal seal:

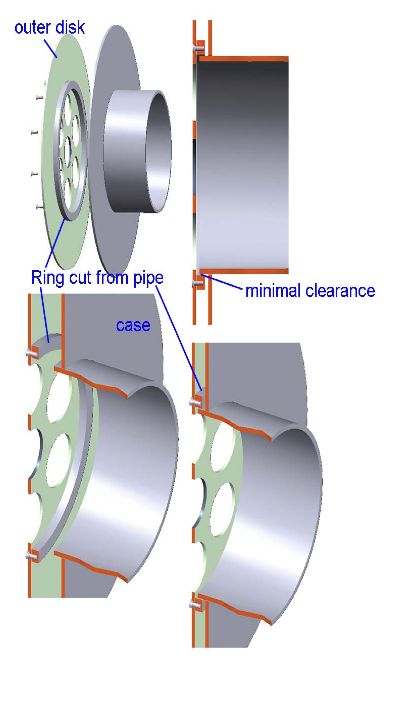

Working fluid must be prevented from escaping past the outer disks so that it can transfer its energy effectively to all the disks. To do this, we put in a ring seal:

Simplified Seal Design

The main seal (not the ballbearing seal) may be simplified as follows:

Bottom Line: Simplicity

The bounary layer turbine is the simplest design of a turbine possible, and it has a respectable efficiency of 25% without optimization. For the significantly lower simplicity and cost, it's a competitor with bladed steam turbines. Compare this to the steam turbines of modern power plants, and you can appreciate the difference:

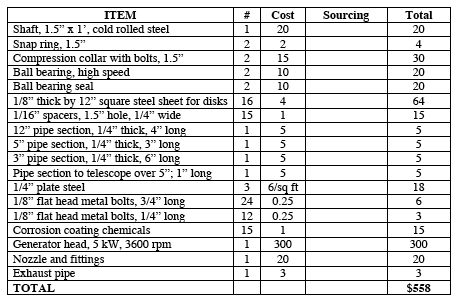

Bill of Materials: Boundary Layer Turbine

The materials cost for the boundary layer turbine, including generator head, is:

Development Log

See the Turbine Development Log.

Turbine Fabrication: General

Initial proposed fabrication procedure is at Turbine Fabrication - from February, 2008.

May 2008 update: Consider starting with the seal disk instead. Build everything out from there, so that the seal can be matched perfectly to the end plate. Use cross-tie bolts instead of a large number of small screws for holding the turbine together. Use square end plates, not round, to facilitate mounting of finished turbine to a stand. The case looks like this from the outside:

If one considers this carefully, then the fabrication procedure is simplified to these basic steps:

- Disks and spacers laser cut professionally ($300 + stainless steel materials)

- Start with a sheet of metal for the seal disk. Hold workpiece with external jaws on a lathe. Cut out inner shaft hole, then the disk itself.

- Take square piece of metal for the end plate, chuck it up with external jaws . Lathe out shaft hole, then the seal indentation, using the seal itself to measure for perfect fit.

- Lathe out bearing mount from a suitable pipe section

- Lathe out mid pipe section - needs smooth ends

- Set retaining ring grooves in the shaft.

- A square piece can be used for the exhaust manifold end plate. Tap 3 bolt holes in the end plate, to hold down end plate on top of exhaust mainfold pipe section.

- Cut the exhaust mainfold pipe section to size on a lathe

- Lathe out the spacer to size

That is basically it. Match the shaft seal and bearing. Please fill in details or alternative procedures. I think this is the simplest possible construction.

Marcin

Turbine Fabrication: Materials and Tolerances

Materials:

We begin with a shaft. It should be some form of hardened steel, either machinable hardened tool steel (using a carbide bit) or A36 that is subsequently hardened. Hardening may be performed by any form of surface treatment. If heat treatment is used for hardening, attention must be given to possible distortion.

The case can be any machinable steel. Zinc galvanization spray, gun-blue, black oxide, or nitriding may be used for corrosion resistance from steam.

Tolerances:

- Shaft: 1.500" +0.0000/-0.0005

- Disks: laser cut - see Turbine Fabrication#Disks.

- Radial spacing between disks and outer case: 10-20 thousandths of an inch

- Shaft and bearings end sections:

- Distance between shaft and ballbearing inner race: -0.0005/+0.000 inch

- Distance between outer race of bearning and housing: -0.000/+0.002 inch

- Spacer 1-2 thousandths tolerance around shaft

- Main seal disk: +/- 0.001 match to side circular plate; zinc coat on disk and side plate will make a perfect match

Sizes:

- Pipe section by bearings: 7/16-3/4" thick to accommodate bearings and seals; depends on bearing OD

Other Construction Details:

Prototype Adaptability:

The prototype of the present, simplified design should be made such that it can be modified readily. As already mentioned in Design Rationale, the entire assembly is held together by compression collars, where the collars are fixed in position by e-rings. Moreover, the pipe sections, including the exhaust shroud, should be bolted with countersunk bolts. As such, the entire device can be taken apart by taking off the e-ring, loosening the collar, unbolting the case, and the entire device can be taken apart.

Using this design, the device can be scaled and modified. Additional disks may be added for more power, and the outer case may be substituted with a longer one. Tolerances can be changed by replacing the case and other components. As such, the device is a testbed for modification. Each modification step requires the replacement of a part, not the entire machine.

- Use bolts for outer case, and for end case section

Gussets

Note that prior work has reinforcing gussets on the end plates. These gussets are avoided in this design by using thicker end plates, 5/16" thick. Gussets, if welded, give thermal distortion to the case.

Main Seal Disk

- 1/4 or 5/16 thick to provide maximum overlap with end circular plate

Nozzle

- Nozzle was brazed from workable sheet metal

- Inlet pipe: 1"

Other

- Use 3/16" bolts to bolt case together, or common #10 bolts

- Use stainless steel bolts for end pipe section - bolts in contact with steam

- Counterbore if use socket head cap screws

- Use red silicone seals between spacer and end pipe section; or use Parker o-rings

- Fabricate end pipe sections first, to fit the bearing and seals

- Match this to end circular plate, bolt it to end circular plate

- Countersink bolt holes for end pipe section; thread the end pipe section

Prior Work

Granett Engineering

A working model of this turbine has been built several years ago. This model was more involved with respect to the fabrication procedure. The present work is a simplification in design. See here.

The prior work featured a turbine without seals between the outside rotor disk and the case. This means that the working gas was escaping partly out the side. Nonetheless, the past work succeeded in producing a whopping 4 kW of electric power when connected to the generator: it lit up a bank of 8, 500W shop lights.

For testing of the prior work, a 50 gallon shop air compressor was discharged at 150 PSI through a 1" diameter pipe nozzle connection. The turbine ran for 30-60 seconds on one charge of said shop air. The angle of the nozzle was varied, but no noticeable difference in power was observed. Additional data acquisition to test the nozzle angle dependence was not taken. The nozzle used had a rectangular outlet and a constriction in the middle, so that it functioned as a jet venturi that increased the flow velocity of the working gas as it entered the turbine.

The turbine gas inlet was shaped like an 'upside down nose' (see picture) in order to accommodate different nozzle angles. Special attention needs to be taken to ensure that the nozzle is coupled firmly to the case entry, to prevent leakage.

The nozzle was directed tangentially to the outside rim of the rotor disks. The width of the gas inlet spanned the width of all the disks, approximately 1.5 inches. The suggested inlet shape is rectangular.

The nozzle was formed out of bendable sheet metal and brazed together. It was then brazed to a 1" inlet pipe for the working gas. In order to form a venturi shape, a constriction was formed in the middle of the nozzle.

Warren Rice, University of Arizona

Link to another Warren Rice paper - [1] See the reference:

Rice, Warren, Transactions of the ASME, Journal of Engineering and Power, January 1965, pp. 28-36

Here are the results in the above paper. Case 1 was a 7" diameter turbine, with 9 disks of 1/32" thickness and disk spacing of 1/16" (check these thicknesses - these numbers were hardly legible in my copy of the paper). Here are the results of this turbine, which was the first prototype explored in the paper:

Picture of turbine without case:

Picture of plumbed turbine:

Picture of plumbed turbine:

The same turbine was modified to reduce the spacing to 1/25", and adding 2 more disks, so that 11 disks were fitted into the same case:

The results may be extrapolated as follows to the Factor e Farm implementation. First, the paper stated explicitly that the results were nowhere close to predicted theoretical results. Take the second set of results:

- Air pressure input: 100 psi

- Mass flow of air: 4.4 lb/min

- Inlet air temperature: 175F

- Rotation speed: 9000 rpm

- Power output: 1.5 hp

- Efficiency: 22%

Compare to the first set of results:

- Air pressure input: 100 psi

- Mass flow of air: 4.9 lb/min

- Inlet air temperature: 100F

- Rotation speed: 9000 rpm

- Power output: 1.1 hp

- Efficiency: 17%

It appears that power scales with the number of disks for a given mass flow of working fluid. We should obtain 22% or higher efficiency with 16 disks - all other factors being equal.

Dan Granett's prototype indeed yielded 4 kW of electrical power for at least 15 seconds - which is consistent with these results. He used about 50 gallons of air at 140 psi - or about .2 cubic meters or about 5 lb of air. If the turbine ran for 15 seconds - then the mass flow rate was about 20 lb/min - at 3600 rpm - with disk spacing of 1/32".

Mass flow of 4.9 lb/min is 300 lb/hour - or about 30 gallons of water if water were the working fluid. If we can generate this much steam, then we would have a working turbine

Bladed Turbine

For comparison, examine the results obtained from a solar concentrator bladed turbine - http://www.redrok.com/engine.htm#newton . This example shows a mass flow rate of steam of 5 g/second - or 300 g/minute - or .7 lb/minute.

The conclusions in this project were:

- Total conversion efficiency (solar power in/electricity out) - 2%

- Conversion of ~10 kW thermal power to ~200W electric power

- Insonsistencies (aka bullshit results) are found here as well: the average shaft power (Section 3.6) was 1.3 kW, while the average usable heat from the concentrator was 1 kW. My interpretation is that the usable heat was much higher, or shaft power was much lower. This inconsistency makes any of the component efficiency results questionable. The only data that we can reasonably trust is the final output (measured electricity) efficiency, based on a known amount of solar capture.

Results here are a factor of 10 better than the Tesla turbine paper by Warren Rice

Other Work

Look at a great example of a solar turbine (dish concentrator, bladed turbine) for comparison. The publication has many calculations that can be used for reference in other designs. By C. Christopher newton - [2], or on our server - [3]

License

This design is open source. It is placed explicitly in the public domain for the benefit of all humankind. Our license is copyleft. We encourage any user of this information to place any further developments in the public domain for others to build on.

Comments

Please comment here.

See Also

- Bladed Turbine

- Tesla Turbine

- GS Product Design - The 12 inch diameter turbine produced 4 kW of electric power in test runs, at a cost of $500 in materials plus fabrication costs.