Boundary Layer Turbine: Difference between revisions

Jump to navigation

Jump to search

(New page: =Design Rationale= Image:BLT_DR.jpg) |

|||

| Line 1: | Line 1: | ||

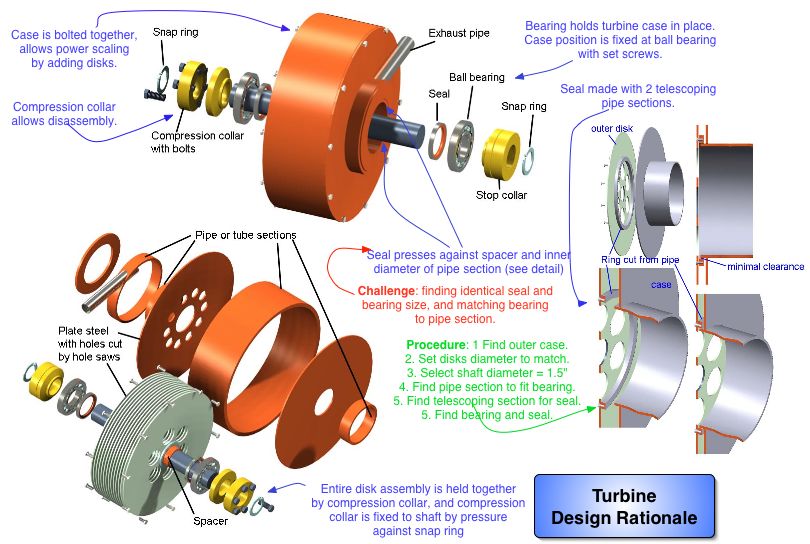

=Design Rationale= | =Design Rationale= | ||

Drawings by Dan Granett, Granett Engineering: | |||

This is an external combustion engine with proven efficiencies of 25% for un-optimized models. A working fluid spins this turbine by means of surface friction. When the disk spacing is small (on the scale of a millimeter), energy transfer from the working fluid to the disks can be efficient. Design rationale: | |||

[[Image:BLT_DR.jpg]] | [[Image:BLT_DR.jpg]] | ||

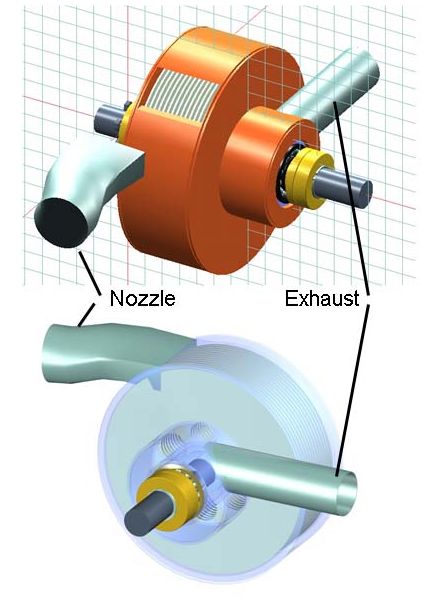

Working fluid (such as steam) enters tangentially to the disks through a nozzle: | |||

[[Image:BLT_nozzle.jpg]] | |||

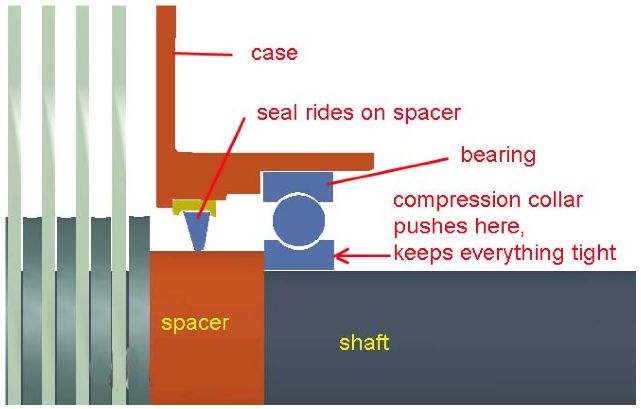

Bearings must be protected from the working fluid with a shaft seal seal: | |||

[[Image:BLT_shaftseal.jpg]] | |||

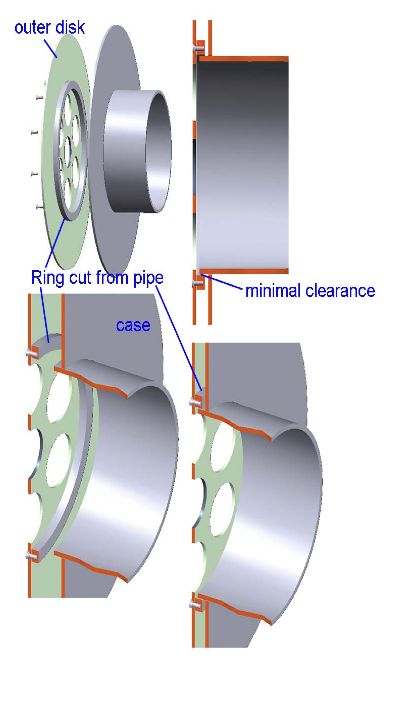

Working fluid must be prevented from escaping past the outer disks so that it can transfer its energy effectively to all the disks. To do this, we put in a ring seal: | |||

[[Image:BLT_ringseal.jpg]] | |||

Revision as of 18:18, 26 January 2008

Design Rationale

Drawings by Dan Granett, Granett Engineering:

This is an external combustion engine with proven efficiencies of 25% for un-optimized models. A working fluid spins this turbine by means of surface friction. When the disk spacing is small (on the scale of a millimeter), energy transfer from the working fluid to the disks can be efficient. Design rationale:

Working fluid (such as steam) enters tangentially to the disks through a nozzle:

Bearings must be protected from the working fluid with a shaft seal seal:

Working fluid must be prevented from escaping past the outer disks so that it can transfer its energy effectively to all the disks. To do this, we put in a ring seal: