D3D Fusion Printer Conceptual Design: Difference between revisions

(Created page with "The purpose of this document is to refine the D3D_Printer_Design#Requirements and to identify meaningful sub-modules. = The Design Recipe = The formal methodology is insp...") |

No edit summary |

||

| Line 50: | Line 50: | ||

=== Build Material === | === Build Material === | ||

We expect | We expect | ||

= Sources Driving Design Desicions in Priority Order = | |||

#[[D3D_Fusion_printer_design#Higher_Level_Goals]] | |||

#[[D3D_Fusion_printer_design#Desired_Attributes]] | |||

#[[D3D_Fusion_printer_design#Functional_Requirements]] | |||

#[http://reprap.org/wiki/RepRap_Interface_Standard RepRap Interface Standard] | |||

Revision as of 12:34, 7 January 2016

The purpose of this document is to refine the D3D_Printer_Design#Requirements and to identify meaningful sub-modules.

The Design Recipe

The formal methodology is inspired by the design recipe taught in the book How to Design Programs. The recipe is a systematic approach to design of programs that can be applied in general with slight rewrites. Here we will recursively apply it to modules and sub-modules. The recipe consists of six steps:

Problem Analysis Give the thing we're going to design and build a name and describe the types of input and output (a "signature" or "contract").

Purpose Statement Reformulate eventual problem statements into a couple of sentences explaining the purpose of the thing we're designing.

Examples Illustrate the purpose statement by listing some example usages of the soon-to-be designed thing. These serve as criteria of success and are used as tests later.

Sketches Some basic shape and logic of the design is already given at this stage. Write it down.

Being creative This is where the designer starts test putting together parts in ways that will solve the problem.

Testing The creation of a test suite from examples ensuring small inputs work as expected.

The book also ponders the programming-equivalent of the mantra:

The shape of the input determines the shape of the design and tests.

3D Printer

Signature

From an abstract input/output point of view, a 3D printer can be said to have the following signature.

- 3D Printer: Power, Build material, Supporting surface(s), Instructions → Physical object

Purpose Statement

A 3D printer is a machine that synthesizes build material into 3D objects according to a series of pre-determined instructions.

Examples

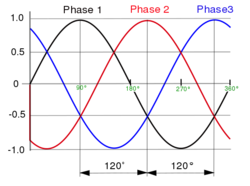

We will assume that a mains voltage will power the 3D printer, with the constant shape:

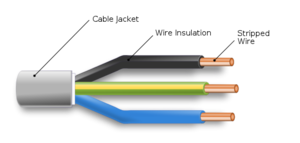

For the build material, we will assume filaments behaving roughly as thermoplastics with the constant shape: ...

Being Creative

Shape of Inputs

Build Material

We expect