Power Cube v16.8: Difference between revisions

Tom Griffing (talk | contribs) |

Tom Griffing (talk | contribs) |

||

| Line 54: | Line 54: | ||

Snapshot: Hydraulic ports - 2 3/4" male outputs from the top of the pumps, 2 3/4" female returns and 1 1/4" low pressure return. | Snapshot: Hydraulic ports - 2 3/4" male outputs from the top of the pumps, 2 3/4" female returns and 1 1/4" low pressure return. | ||

[[Image:PC16.8HydraulicPorts.png Hydraulic Ports]] | [[Image:PC16.8HydraulicPorts.png Hydraulic Ports|600px]] | ||

==Question== | ==Question== | ||

Revision as of 02:14, 30 August 2016

Latest version: (download here - you can also download STL for printing)

Development Spreadsheet

Other Modules

Introduction

The Power Cube, Version 15.6 is a powerful, portable hydraulic power supply that operates efficiently and with minimal noise. The latest design employs twin 18 HP engines and fixed-displacement hydraulic pumps that have proven to work well with OSE machines and for other compatible hydraulic machines. This version includes a frame of 4" x 4" tubular steel that provides a strong structural frame for mounting other power cubes or attachments.

The Power Cube marks the next level of quick connect modularity, making it easy to assemble, use and maintain and is standard for all hydraulic equipment in the Global Village Construction Set.

NOTE: This document is still under development and is not ready yet for "Prime Time" fabrication. This note will be removed when it has reached a "comfortable" level of completion.

Features

- Compact hydraulic power source for OSE and other compatible hydraulic tools

- Electric start, 18 horsepower air-cooled engines

- Commercial fuel tank and muffler for low noise level

- Controls easily accessible for safety and comfort

- Standard quick connect hydraulic couplers

- Modular design simplifies maintenance and parts replacement

- 9 gallon oil reservoir

- Heavy duty 6-tube oil cooler with fan cool the hydraulic fluid

- Sturdy tubular frame protects unit from damage and provides a simple means for adding attachments

- Pressure relief valve limits the output pressure for safety

- Pressure gauge

Specifications

- Model: OSE Power Cube, Version 16.8

- Engine: Duromax, 18 HP

- Fuel Capacity: 10 Gallons

- Pressure (maximum): 3000 PSI

- Flow (maximum): 15.2 GPM

- Weight (approximate): 400 lbs

Development

Published the latest design in Sketchup below

This design has proven to work well and has had few updates lately. Here are the latest updates:

Aug 2016: Twin 18HP engine design in the works - mostly complete, will be built in the September Power Cube workshop

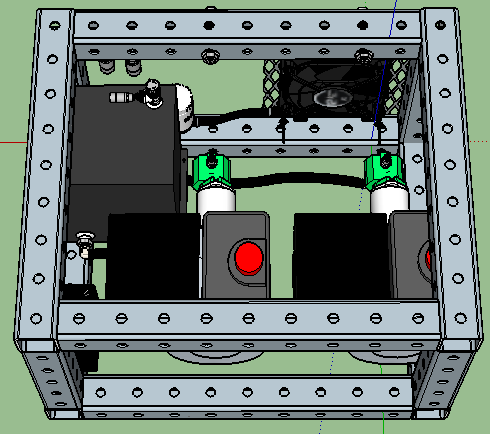

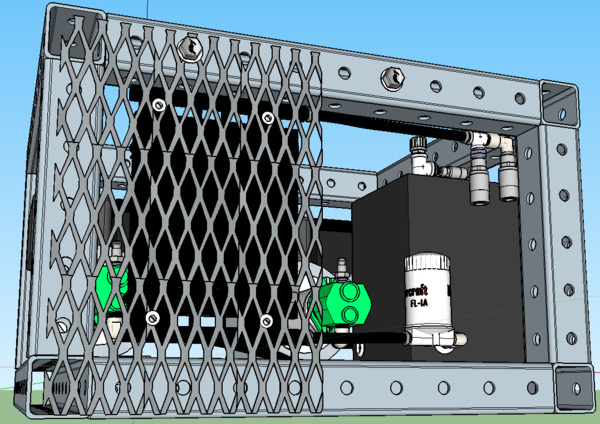

Snapshot: Hydraulic ports - 2 3/4" male outputs from the top of the pumps, 2 3/4" female returns and 1 1/4" low pressure return.

Question

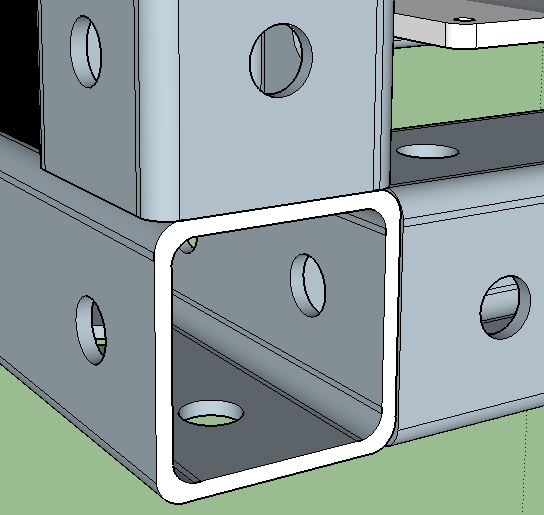

How should corners be formed and welded for optimal strength? Here is one image of a corner, with one of the horizontal members in the corner and the others welded to it:

Should the orientation be the same for all 8 corners?

Should we employ any special grinding / welding procedures for the one weld where all three members meet?

Files

These is the latest release of the v16.8 Power Cube with twin engines.

Bill Of Materials (BOM): Power Cube BOM

- DuroMax Engine Specs File:Duromax Engine.pdf

- Power Cube v16.8 Sketchup File:PC16-8.skp

Fabrication Steps

The Power Cube is a modular design. The modules are built separately, then combined for the complete Power Cube. The order of module fabrication is not important, but they are all necessary to complete a Power Cube.

Module fabrication procedures are detailed in the following document:

Wiring Harness

The Wiring Harness

Final Assembly

- Install Hydraulic Reservoir module in frame

- Install Pump module

- Install oil cooler and fan to expanded steel

- Install hoses to connect hydraulics and tighten appropriately

- Install Wiring Harness