Biodiesel: Difference between revisions

mNo edit summary |

mNo edit summary |

||

| Line 16: | Line 16: | ||

== No Conversion: using straight vegetable oil == | == No Conversion: using straight vegetable oil == | ||

While straight vegetable oil can be used as fuel (new, or waste frying oil), it has a negative effect on the engine after prolonged use. Thus it is usually better to process the oil into biodiesel, especially for heavily used engines. | While straight vegetable oil can be used as fuel (new, or waste frying oil), it has a negative effect on the engine after prolonged use. Thus it is usually better to process the oil into biodiesel, especially for heavily used engines. | ||

== Sources == | == Sources == | ||

| Line 27: | Line 21: | ||

*vegetable oils, which are now often cheaper than regular fuel, if bought in bulk, and we consider that premium cooking oils are not needed. | *vegetable oils, which are now often cheaper than regular fuel, if bought in bulk, and we consider that premium cooking oils are not needed. | ||

*used deep frying fat or oil (which would normally be discarded, at economic and environmental cost) - take-away food shops typically have a regular output of this waste. | *used deep frying fat or oil (which would normally be discarded, at economic and environmental cost) - take-away food shops typically have a regular output of this waste. | ||

*Pyrolysis oil or "bio-oil" can indeed be a feedstock for biodiesel production. However, it contains aqueous components as well as acidic oily components that have to be separated out. Please see the wiki pages on [[Biochemicals_from_Pyrolysis|biochemicals from pyrolysis]] and [[Pyrolysis_Oil_from_Biomass|bio-oil]] for more details. | |||

==Mixing Biodiesel and Bio-Oil== | |||

Pyrolysis oil can be mixed with biodiesel for a low-cost, diesel-like fuel. More details [[Bio-Oil_/_Diesel_Mixture_Fuels| here]]. | |||

== Suggested projects == | == Suggested projects == | ||

Revision as of 01:03, 7 March 2011

Biodiesel is made from fat or oil. This involves chemically modifying the oil as to give it properties more closely resembling diesel fuel. It can be used in nearly any diesel engine, with little or no modification. However, biodiesel is a stronger solvent than regular diesel, which can impact rubber components. Biodiesel produces less particulates than petrodiesel and is thus better for air quality. (Note: this page was largely transwikified from Appropedia but we have given them so many pages it's about time we got something in return, yathink ?).

Vegetable oil extraction and conversion

The process of oil extraction is carried out the same way as for extraction of edible oil from plants. There are many crops grown in rural areas of the developing world which are suitable for oil production – sunflower, coconut, cotton seed, palm, rapeseed, soy bean, peanut, hemp and more. Sunflower oil, for example, has an energy content about 85% that of diesel fuel.

There are two well-established technologies for oil extraction:

- The simple screw press, which is a device for physically extracting the oil from the plant - this technology is well suited to small-scale production of oil as fuel or as foodstuff in rural areas. The press can be motorised or hand-operated.

- Solvent extraction is a chemical process which requires large, sophisticated equipment. This method is more efficient - that is, it extracts a greater percentage of the oil from the plant - but is less suited to rural applications.

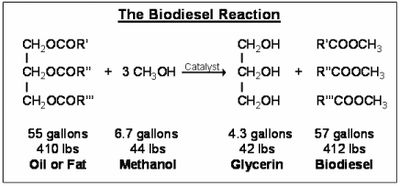

Conversion: the Biodiesel Process

Biodiesel production is not complex and can be done on a small scale. Please see our blog post: Open Source Biodiesel Tutorial for more details. In a nutshell, the vegetable oil is converted to a useable fuel by adding ethanol or methanol alcohol along with a catalyst to improve the reaction. Small amounts of potassium hydroxide or sodium hydroxide (commonly called lye or caustic soda, which is used in soapmaking) are as the catalyst material. Abundant Glycerol separates out as the reaction takes place and sinks to the bottom of the container. This "waste" product has many uses, so not a problem. The glycerine can be used as a degreasing soap or refined to make other products. This removes the component that gums up the engine so that a standard diesel engine can be used.

No Conversion: using straight vegetable oil

While straight vegetable oil can be used as fuel (new, or waste frying oil), it has a negative effect on the engine after prolonged use. Thus it is usually better to process the oil into biodiesel, especially for heavily used engines.

Sources

Biodiesel can be made from many fats or oils, such as:

- vegetable oils, which are now often cheaper than regular fuel, if bought in bulk, and we consider that premium cooking oils are not needed.

- used deep frying fat or oil (which would normally be discarded, at economic and environmental cost) - take-away food shops typically have a regular output of this waste.

- Pyrolysis oil or "bio-oil" can indeed be a feedstock for biodiesel production. However, it contains aqueous components as well as acidic oily components that have to be separated out. Please see the wiki pages on biochemicals from pyrolysis and bio-oil for more details.

Mixing Biodiesel and Bio-Oil

Pyrolysis oil can be mixed with biodiesel for a low-cost, diesel-like fuel. More details here.

Suggested projects

- Search for literature discussing the health impacts of vehicle pollution, and different aspects of the pollution such as particulates vs other pollutants.

- Design a relatively simple, reliable way of converting vegetable oil (waste and/or new) into biodiesel, to minimize the technical expertise and resources needed, perhaps making it more practical for production in small or medium-sized remote towns.Template:Sp

External links

- "Make your own biodiesel" from Journey to Forever

- Biodiesel Blog

- Footprint Recycling, providing biodiesel in Humboldt County, California

- NREL Biodiesel - This is an excellent PDF going into some of the technical details of the chemistry and processes behind biodiesel production.

- Guide to Biodiesel