CEB Press/Manufacturing Instructions/Frame with main cylinder: Difference between revisions

Jump to navigation

Jump to search

William Neal (talk | contribs) No edit summary |

No edit summary |

||

| Line 1: | Line 1: | ||

{{Category=CEB press building instructions}} | {{Category=CEB press building instructions}} | ||

== Tools Required == | ==Tools Required== | ||

*Torch | |||

*Hole Punch | |||

*Mag Drill | |||

*1/2” Allen Wrench | |||

* | ==Materials Required== | ||

* | ===Steel=== | ||

*6” Heavy (7/16”) U-Channel- 274 1/2” | |||

**A- 54” (2); Vertical Members | |||

**B- 20 3/4” (4); Horizontal Members | |||

**C- 28 3/4” (2); Drawer Members | |||

**D- 13” (2); Spacers | |||

*2”x2”x1/4” Angle Iron: | |||

**E1- Cylinder Cross Supports: E1- Horizontals: 20 3/4” (2) | |||

**E2- Cylinder Cross Supports: E2- Verticals: ?? | |||

**F- 6” (2); Dirt Blockers | |||

*1 1/2” DOM Roundstock: 12”; Cylinder Pin: 8 1/2”, Press Foot Filler: 3 1/2” | |||

*1 1/2” Inter Diameter DOM Tubing: 1 1/4” (2); Pin Receptors | |||

*1”x4” Plate: Lower Press Foot: 10” (1) | |||

*1”x6” Plate: Upper Press Foot: 12” (1) | |||

*2” U-Channel: 1.5” (2); Cylinder Spacers | |||

*1” Pipe: 1.5” (2); Cylinder Spacers | |||

*1/4”x1” Flatbar: 13” (1); Magnet holder | |||

*3/8” Rebar: 3.5” (2); Sensor Holder | |||

**For Optional “Jig”: 6”x12” Tubing: 52” | |||

== | ===Nuts and Bolts=== | ||

* | *3/4”x1.5” Bolts (28) | ||

*3/ | *3/4” x 2.5” Bolts (6) | ||

*3/ | *3/4” Steel Nuts (9) | ||

* | *3/4” Galvanized Nuts (40) | ||

* | *3/4” Threaded Rod: 16” | ||

* | |||

===Hydraulics=== | |||

*5”x12” 3000 PSI Hydraulic cylinder [https://www.surpluscenter.com/item.asp?item=9-1143-12&catname=hydraulic Buy] (1) | |||

*3/4” to 3/4” Hydraulic Coupler (2) | |||

*3/4” Female Quick Coupler (1) | |||

*3/4” Male Quick Coupler (1) | |||

==Fabrication Instructions:== | |||

===Step 1: Punch the holes in the horizontal members (A) and in the drawer members (B)=== | |||

[[Image:punchedholes.jpg|thumb|Step 1]] | |||

*In the horizontal members, the holes should be 7/8” in from the long side, and as close as you can get them to the wall of the U-channel. There are 4 holes in each piece. | |||

* In the drawer members, the holes should be 4 7/8” in from the long side, and as close as you can get them to the wall of the U-Channel. There are 4 holes in each piece. | |||

===Step 2: Mag Drill Holes in Verticals.=== | |||

#Gather materials for the “Jig”; this means 6”x12” tubing (52”) and any extra heavy U Channel. If you don't have any laying around, you can use one drawer member, and one spacer on each side. | |||

===To be continued, during the month of August, 2011...=== | |||

[[Image:channel.jpg|thumb|Step 1. Torch or cold-cut channel to size]] | |||

[[Image:Framestanding.jpg|thumb| Step 3]] | |||

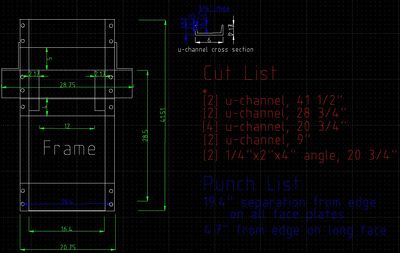

== Diagrams == | == Diagrams == | ||

Revision as of 16:43, 22 August 2011

Main > Housing and construction > CEB Press > CEB press building instructions

Tools Required

- Torch

- Hole Punch

- Mag Drill

- 1/2” Allen Wrench

Materials Required

Steel

- 6” Heavy (7/16”) U-Channel- 274 1/2”

- A- 54” (2); Vertical Members

- B- 20 3/4” (4); Horizontal Members

- C- 28 3/4” (2); Drawer Members

- D- 13” (2); Spacers

- 2”x2”x1/4” Angle Iron:

- E1- Cylinder Cross Supports: E1- Horizontals: 20 3/4” (2)

- E2- Cylinder Cross Supports: E2- Verticals: ??

- F- 6” (2); Dirt Blockers

- 1 1/2” DOM Roundstock: 12”; Cylinder Pin: 8 1/2”, Press Foot Filler: 3 1/2”

- 1 1/2” Inter Diameter DOM Tubing: 1 1/4” (2); Pin Receptors

- 1”x4” Plate: Lower Press Foot: 10” (1)

- 1”x6” Plate: Upper Press Foot: 12” (1)

- 2” U-Channel: 1.5” (2); Cylinder Spacers

- 1” Pipe: 1.5” (2); Cylinder Spacers

- 1/4”x1” Flatbar: 13” (1); Magnet holder

- 3/8” Rebar: 3.5” (2); Sensor Holder

- For Optional “Jig”: 6”x12” Tubing: 52”

Nuts and Bolts

- 3/4”x1.5” Bolts (28)

- 3/4” x 2.5” Bolts (6)

- 3/4” Steel Nuts (9)

- 3/4” Galvanized Nuts (40)

- 3/4” Threaded Rod: 16”

Hydraulics

- 5”x12” 3000 PSI Hydraulic cylinder Buy (1)

- 3/4” to 3/4” Hydraulic Coupler (2)

- 3/4” Female Quick Coupler (1)

- 3/4” Male Quick Coupler (1)

Fabrication Instructions:

Step 1: Punch the holes in the horizontal members (A) and in the drawer members (B)

- In the horizontal members, the holes should be 7/8” in from the long side, and as close as you can get them to the wall of the U-channel. There are 4 holes in each piece.

- In the drawer members, the holes should be 4 7/8” in from the long side, and as close as you can get them to the wall of the U-Channel. There are 4 holes in each piece.

Step 2: Mag Drill Holes in Verticals.

- Gather materials for the “Jig”; this means 6”x12” tubing (52”) and any extra heavy U Channel. If you don't have any laying around, you can use one drawer member, and one spacer on each side.

To be continued, during the month of August, 2011...

Diagrams

Step 1: Gather the Form Pieces

Step 2: Put the Form Pieces Together

Step 3: Line the Vertical Beams along the Form and C-Clamp them in Place

Step 4: Place One Each of the Upper and Lower Cross Beams

Step 5: Flip the Frame

Step 6: Place the Remaining Cross Beams

This diagram shows the pieces needed for the frame. Click to enlarge:

Video Explantion