Foundry: Difference between revisions

(→Plans) |

(→Books) |

||

| Line 51: | Line 51: | ||

=Books= | =Books= | ||

*Google Book, '''Maximum Production in Machine-shop and Foundry''' - 150 lb shots in 1911 foundry took 3.5 hours - with noted low production - [http://books.google.com/books?id=4uUNAAAAYAAJ&pg=PA282&lpg=PA282&dq=100+lb+foundry&source=bl&ots=S00WtZMGp_&sig=mxtsCMcC5FZVAzF6KeXKIjhRMUs&hl=en&sa=X&oi=book_result&resnum=1&ct=result#PPA281,M1] | *Google Book, '''Maximum Production in Machine-shop and Foundry''' - 150 lb shots in 1911 foundry took 3.5 hours - with noted low production - [http://books.google.com/books?id=4uUNAAAAYAAJ&pg=PA282&lpg=PA282&dq=100+lb+foundry&source=bl&ots=S00WtZMGp_&sig=mxtsCMcC5FZVAzF6KeXKIjhRMUs&hl=en&sa=X&oi=book_result&resnum=1&ct=result#PPA281,M1] | ||

*Google Book, The Foundry, early 1900s, has economics - [http://books.google.com/books?id=FI9NAAAAMAAJ&pg=RA2-PA44&lpg=RA2-PA44&dq=productive+value+of+a+foundry&source=web&ots=wR_z29twwO&sig=nPBg7UxB7yj11sXmUydtN-xFjMA&hl=en&sa=X&oi=book_result&resnum=2&ct=result#PRA2-PA45,M1] | |||

Revision as of 14:02, 18 January 2009

Introduction

- Steel melts at around 2500F, 1350C, or slightly below pure iron

- Iron melting point - 1540C, 1811K, 2800F

- Cast iron melting point - 1150-1200C, about 300C lower than pure iron

- From [1]:

- Seel is iron and up to 2.0% carbon without any other alloying elements

- Above 2.0% C we are dealing with cast iron. Cast iron tends to be brittle, unless it is ductile cast iron.

- The steel melting point varies between 1540°C and 1400°C, gradually declining with increasing carbon content.

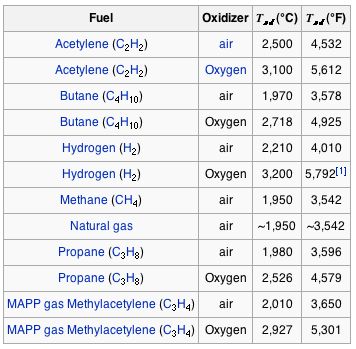

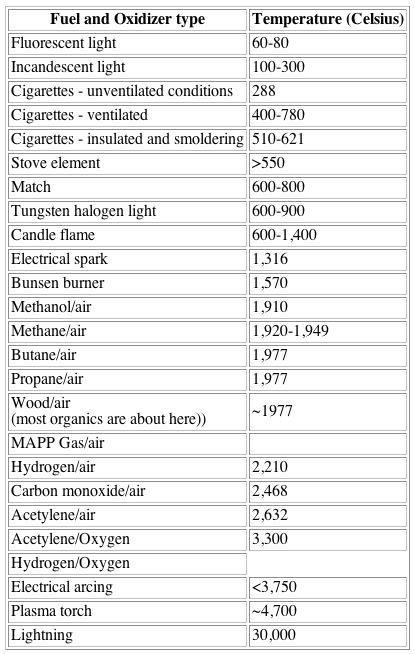

- Flame temperatures from Wikipedia:

- Flame temperatures from [2]:

Foundries

- College foundry, 100 lb steel or iron, 100 kW induction furnace - [3]

- 200 lb dipout furnace for sale - [4]

- 3000F furnace, 750 lb per hour after first heat - electric with 2 electrodes - [5]

- Arc furnace, 175kW, 700 lb/hour - [6]

- Induction Furnace - 40 kW - http://www.ufes.com/index.php?n=Foundry.InductothermInductionFurnaceModel40-96

- ARC, 53kW, 560 lb - [7]

- Induction 4000 lb for 100kW, or 1000 lb for 25 kW? - [8]

Plans

- Plans for a 330 lb/hour iron melting foundry - [9]:

Collaboration Discussions

Letter sent to Paul:

Could you do a little research on foundries? I put initial info up at:

http://openfarmtech.org/index.php?title=Foundry

We want to melt metal - to cast tractor, steam engine, and CEB press parts. We would like to do that this year. Are you by any chance interested in getting involved in this? The workshop will house the furnace.

If so, please research this and propose the best furnace to use. We want to work with steel - so any iron melting furnace will do. We are looking for a simple, low-cost design that can handle at least 200 pounds per hour, to be effective in casting - say the 2000 lb of a tractor frame - in one day.

The economics involved are producing $1000+ worth of structural steel for parts. This would make it economically feasible to produce tractors, etc - starting from scrap steel.

This would be quite a treat, to show fabrication starting at the cost of scrap metal. It's a possibility, but so far I have not seen an integrated operation that designs, casts, and builds under one roof. There is great potential for efficiency through this process, especially if we have global design sharing, and 3D printing of mold via open source printers such as RepRap.

Marcin

Books

- Google Book, Maximum Production in Machine-shop and Foundry - 150 lb shots in 1911 foundry took 3.5 hours - with noted low production - [10]

- Google Book, The Foundry, early 1900s, has economics - [11]