CNCCMV2: Difference between revisions

Jump to navigation

Jump to search

| Line 116: | Line 116: | ||

*The travel range calculation for the X and Y axes are as follows. Assuming that the frame remains an asymmetrical angle-cube, the travel range of the X axis equals that of the Y axis. The travel range for both axes is simply: | *The travel range calculation for the X and Y axes are as follows. Assuming that the frame remains an asymmetrical angle-cube, the travel range of the X axis equals that of the Y axis. The travel range for both axes is simply: | ||

(X or Y Travel Range) = (Distance Between 2 Parallel Angles Along Vertical or Horizontal Plane) - ( | (X or Y Travel Range) = (Distance Between 2 Parallel Angles Along Vertical or Horizontal Plane) - (Length of Platform Along Axis) | ||

*Hence the area covered by both axes are: | *Hence the area covered by both axes are: | ||

Revision as of 23:07, 16 February 2012

Overview

- The CNC Circuit Mill Version 2 is designed for superior ease of sourcing, fabrication, assembly, and disassembly, combined with high performance, scalability, modularity, and lifetime design- all at low cost.

Key Specifications

+1

Performance

- X Axis Travel Range = 20cm

- Y Axis Travel Range = 20cm

- Z Axis Travel Range = 5cm

- Step Motor Torque at 12VDC = 3.2kg-cm

- Spindle Max Rotation Speed = 22600rpm no-load

- Spindle Motor Torque at 24VDC = 88.5g-cm at max efficiency

- Workpiece Holding Mechanism = Linear Bolt and Tensioning Nut

Design

- Stock Steel Cube-shaped External Structure

- Stock Aluminum Angle-based Internal Structure

- Step Motor Axis Drive

- Rotary-to-Linear Motion Converting Stainless Steel Leadscrew and Wear-compensating Leadscrew Nut

- Anti-friction Bronze Sleeve Bearings

- Precision Stainless Steel Axis-Supporting Shafts

- Versatile Fastener-based Holding Platform

- Brushed DC Motor Spindle Drive

- Precision Stainless Steel Spindle Shaft

- Computer to Microcontroller to Stepper Driver Electronics Pathway

- Gcode Streamer to Gcode Interpreter Software Pathway

Cost

- Stock Metal = under 150 USD

- Leadscrews and Leadscrew Nuts = under 250 USD

- Precision Shafts = under 150 USD

- Bearings = under 100 USD

- Fasteners = under 70 USD

- Electronics = under 300 USD

- Software = Open Source

-1

Further Performance Specifications

Design Rationale

Sourcing

- Spreadsheet File

LINK HERE

- Prototyping Spreadsheet

- To edit or download the spreadsheet, click on the following link.

https://docs.google.com/spreadsheet/ccc?key=0AlpsBarfpPkzdFk5aDY3dHM0eEhfZHNkWVppdV9EelE

Build Process

Design Modifications

+1

Modularity

- Different step motors and drive mechanisms can be mounted onto the axis support angles via mounting holes

- Different frames can be used, provided they have precise mounting holes for the axis support angles

- Different holding platforms can be used, provided they have mounting holes for the X axis moving angles

- Different spindle setups can be used, provided they have mounting holes for the Z axis moving angles

- Different stepper driver boards and power supplies can be used, provided they have compatible performance specifications within the electronics system

Scaling

- Scaling mainly consists of changing the size of the frame (to affect travel ranges) and the type of step motors (to affect travel rates)

- Other discrete components such as fasteners, leadscrews, and shafts need only be scaled if necessary for functionality or certain desired performance specifications

- The travel range calculation for the X and Y axes are as follows. Assuming that the frame remains an asymmetrical angle-cube, the travel range of the X axis equals that of the Y axis. The travel range for both axes is simply:

(X or Y Travel Range) = (Distance Between 2 Parallel Angles Along Vertical or Horizontal Plane) - (Length of Platform Along Axis)

- Hence the area covered by both axes are:

(XY Travel Area) = (X or Y Travel Range)^2

-1

Usage

- Circuit Schematic to Gcode File Toolchain

- See following link for list of electronic design suites:

http://en.wikipedia.org/wiki/Comparison_of_EDA_software

- PCB-Gcode Optimizer

http://cnc.goodbits.net/wiki/index.php5/Pcb-gcode_optimizer

http://www.millpcbs.com/index.php?option=com_content&view=article&id=10&Itemid=44

Maintenance

Distributive Enterprise

+1

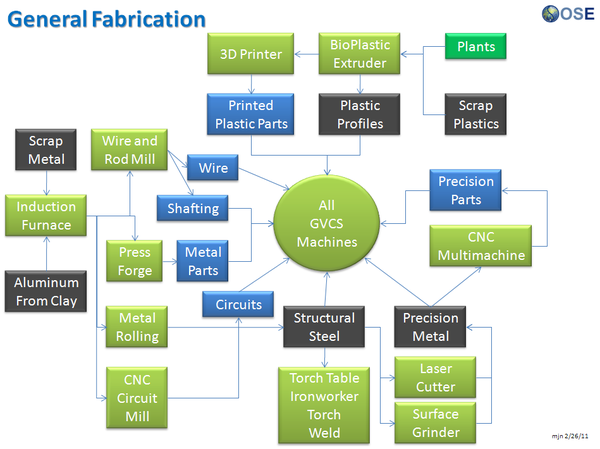

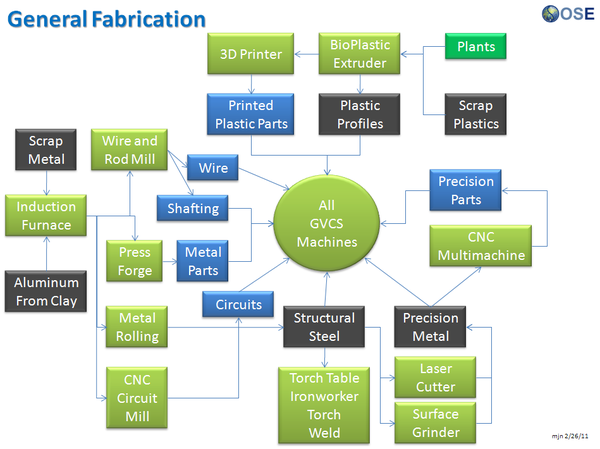

GVCS Product Ecology

CNC Circuit Mill Product Ecology

Uses

- Induction Furnace - Steel

- Aluminum Extractor - Aluminum

- Metal Roller - Fasteners, Metal Angles, and Flats

- Rod and Wire Mill - Wires, Shafts

- CNC Multimachine - Bearings, Leadscrews, Leadscrew Nuts

- Motors - XYZ Movement

- CNC Circuit Mill - Control Circuit Boards

- Universal Power Supply - Power

Creates

- Milled Circuit Boards

See Product Ecologies for more information.