CNCCMV2/Structure/Techniques: Difference between revisions

Jump to navigation

Jump to search

(Created page with "=Point Marking with Datum Point/Edge= *Measure the appropriate distance from the datum point/edge and scribe the length point with 2 small lines *Repeat for all dimensions, all...") |

|||

| (14 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

=Point Marking with Datum | =Point Marking with Datum Points and Edges= | ||

* | *Datum points and edges are points and edges of the workpiece that you measure from. | ||

* | *In most cases, 2 datum edges will be used. How to measure using 2 datum edges is shown in the diagram below. | ||

[[Image: 2datumedges.gif]] | |||

*When marking to drill, center punch the points so that that drill bit centers into the desired position during the operation. | |||

=Match Drilling= | =Match Drilling= | ||

* | *Match drilling is the process of drilling through multiple components at the same time so that the final assembly is aligned perfectly. | ||

*Match drilling works effectively with templates. For instance, a template can be placed on top of a component, then match-drilled; the template can be reused for other components which require the same hole pattern. This template multi-usage is useful when multiple components need excellent alignment but are too large or irregularly-shaped to be match drilled together. | |||

*A process similar to match drilling is to drill a workpiece before it is cut apart to separate components. For example, a 100cm metal rod can be drilled through, then cut in half so that the holes of the two 50cm metal rods align perfectly together. | |||

*Match drilled components mounted with a C-clamp are shown below. Those bronze rod-like things are called clecos; clecos hold the components aligned together during drilling (extra secure than just with the initial clamps), especially useful for large multi-hole operations. | |||

[[Image: matchdrillcleco.jpg]] | |||

=Mounting= | |||

*Rotating components such as drill bits and parts to be lathed require the use of a chuck. | |||

*A lathe chuck is shown below. | |||

[[Image: lathechuck.jpg]] | |||

*A drill chuck is shown below. | |||

[[Image: drillchuck.jpg]] | |||

*Stationary components such as those to be operated on by a drill press require the use of clamps, vises. | |||

*Drill press clamp below. | |||

[[Image: drillpressclamp.jpg]] | |||

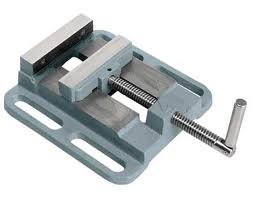

* | *Drill press vise below. | ||

[[Image: drillpressvise.jpg]] | |||

Latest revision as of 14:41, 25 April 2012

Point Marking with Datum Points and Edges

- Datum points and edges are points and edges of the workpiece that you measure from.

- In most cases, 2 datum edges will be used. How to measure using 2 datum edges is shown in the diagram below.

- When marking to drill, center punch the points so that that drill bit centers into the desired position during the operation.

Match Drilling

- Match drilling is the process of drilling through multiple components at the same time so that the final assembly is aligned perfectly.

- Match drilling works effectively with templates. For instance, a template can be placed on top of a component, then match-drilled; the template can be reused for other components which require the same hole pattern. This template multi-usage is useful when multiple components need excellent alignment but are too large or irregularly-shaped to be match drilled together.

- A process similar to match drilling is to drill a workpiece before it is cut apart to separate components. For example, a 100cm metal rod can be drilled through, then cut in half so that the holes of the two 50cm metal rods align perfectly together.

- Match drilled components mounted with a C-clamp are shown below. Those bronze rod-like things are called clecos; clecos hold the components aligned together during drilling (extra secure than just with the initial clamps), especially useful for large multi-hole operations.

Mounting

- Rotating components such as drill bits and parts to be lathed require the use of a chuck.

- A lathe chuck is shown below.

- A drill chuck is shown below.

- Stationary components such as those to be operated on by a drill press require the use of clamps, vises.

- Drill press clamp below.

- Drill press vise below.