|

|

| (59 intermediate revisions by the same user not shown) |

| Line 1: |

Line 1: |

| =Block Uniformity= | | =Assemblies= |

|

| |

|

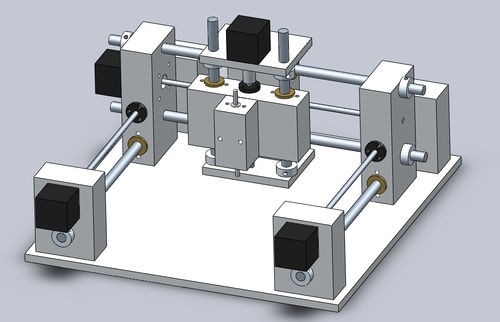

| *Keep 2 block dimensions same for all blocks | | *[[Image: CNCCMV2.jpg|500px]] |

|

| |

|

| *Based on the conceptual design, 1 of the block dimensions will solely be used to fit the diameter of the leadscrews, precision shafts, and sleeve bearings. | | *[[Image: CNCV2XAxis.jpg|500px]] |

|

| |

|

| *The other block dimension to be uniform will mostly support the part by its length on precision shafts.

| | =Manufacturing= |

|

| |

|

| *For accomodating leadscrew nuts up to 10mm or 3/8" dia, dimension 1 will be 40mm.

| | [http://opensourceecology.org/wiki/CNCCMV2/CAD/Templates Templates] |

|

| |

|

| =Stepper Motor Mount Uniformity= | | =Parts= |

|

| |

|

| *Use the same stepper motor type for each axis.

| | [http://opensourceecology.org/wiki/CNCCMV2/CAD/Structure Structure] |

|

| |

|

| *Nema 17 steppers for appropriate performance characteristics.

| | [http://opensourceecology.org/wiki/CNCCMV2/CAD/Shafts Shafts] |

|

| |

|

| *Standard 31mm center-to-center mounting holes. Modular.

| | [http://opensourceecology.org/wiki/CNCCMV2/CAD/CollarsCouplings Collars and Couplings] |

|

| |

|

| =Sleeve Bearing Mount Uniformity=

| | [http://opensourceecology.org/wiki/CNCCMV2/CAD/Bearings Bearings] |

|

| |

|

| *Use the same sleeve bearing type throughout machine

| | [http://opensourceecology.org/wiki/CNCCMV2/CAD/Fasteners Fasteners] |

|

| |

|

| *2 fastening holes on the part to which sleeve bearing should be mounted. For sleeve bearing of 24mm diameter, mount circle with 10+15mm washers and 1mm clearance should be 24 + 10 + 2 = 36mm diameter.

| | [http://opensourceecology.org/wiki/CNCCMV2/CAD/Drive Drive] |