Cold Saw/V1 Design Rationale: Difference between revisions

| Line 82: | Line 82: | ||

*'''Vise Mechanism''' | *'''Vise Mechanism''' | ||

Vise Mounting Rectangle Sides: | Vise Mounting Rectangle Sides: 50mm x 90mm | ||

Center-to-Center Distance Between Vise Shaft and Threaded Rod: 95mm | Center-to-Center Distance Between Vise Shaft and Threaded Rod: 95mm | ||

Revision as of 18:20, 4 June 2012

Basic Concept

A blade rotates. The blade and/or workpiece move toward the other. The blade cuts the workpiece.

Notes: The blade should move toward the workpiece in order to facilitate angled cuts which would otherwise require rotation of the workpiece about the vertical axis, which is practically incompatible with linear workpiece feed (imagine having to move around heavy linear feed equipment at the side of the cold saw for every angled cut)

Features

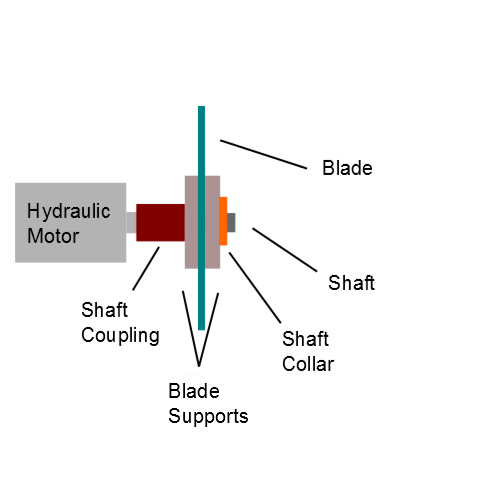

- Hydraulic Direct Drive (to provide high torque and low speed operation without complex transmission)

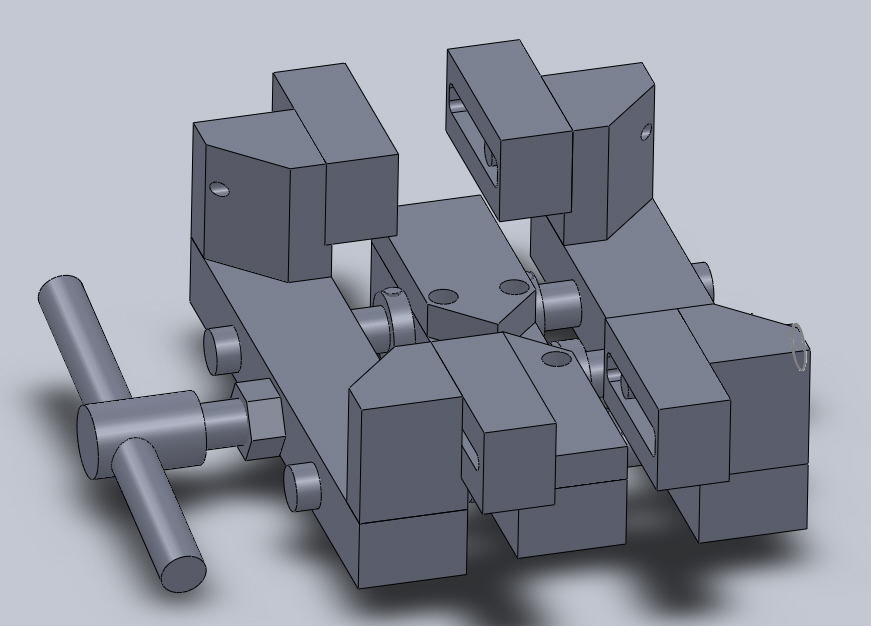

- Auto-Centering Vise (to improve cut quality and to fit more workpiece sizes and shapes)

Shaft Collar and Thrust Washer Notes: The shaft collars prevent the shafts and threaded rod from moving under friction and handle rotation, respectively. The thrust washers minimize friction caused by the rotation of the threaded rod's shaft collars under clamping tension.

Cut Location Notes: If the cut occurs at the center of the clamping volume, we achieve maximum clamping rigidity and optimal vise dimensions to facilitate angled cuts (because the vise needs a wide mouth for angled cuts, better to go wide from the center than anywhere else for maximum rigidity and dimensional uniformity).

Cut Depth Notes: At all possible cut angles, the blade must not contact the vise.

Vise Dimensional Notes: The vise achieves maximum rigidity and minimum material usage when its clamping volume is as close to its mounting surface as possible.

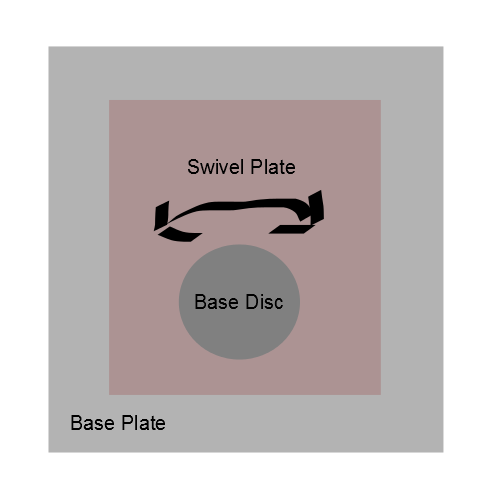

- Swivel Head (to allow angled cuts)

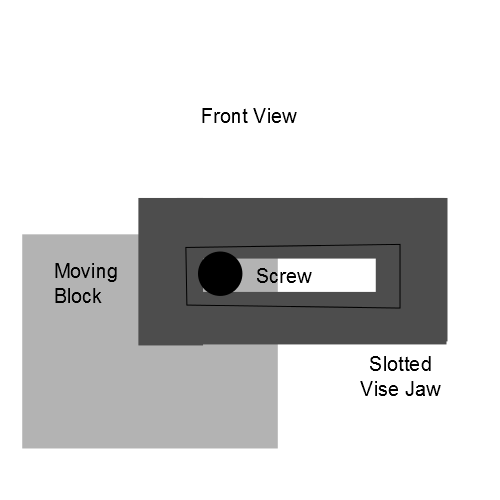

- Adjustable and Removable Vise Jaws (to accommodate variety of workpiece shapes and dimensions)

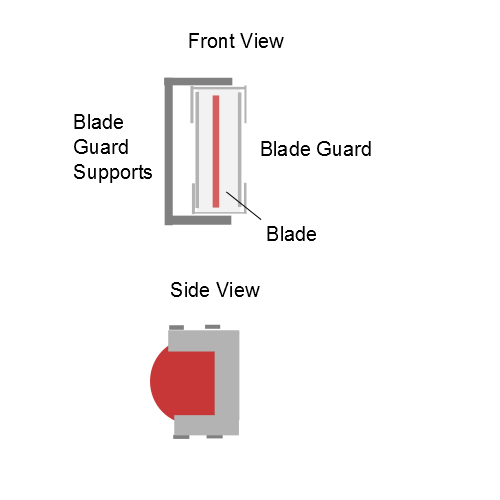

- Fixed Blade Guard (to protect against unintended blade contact during operation)

- Forward and Backward Drive Stops (to prevent cutting into vise and to hold blade in mid-air while mounting the workpiece)

Uniform Part Dimensions

- Plate: 25.4mm x 304.8mm (Base Plate, Swivel Plate)

- Flat Bar: 76.2mm x 50.8mm (Shaft Block, Fixed Block, Moving Block)

- Flat Bar: 25.4mm x 127mm (Support Bar, Bridge Bar, Interface Bar, Vise Jaw)

- Flat Bar: 3.175mm x 25.4mm (Blade Guard Support)

- Flat Bar: 1.6mm x 152.4mm (Blade Guard)

- Round Bar: 152.4mm DIA (Base Disc)

- Round Bar: 127mm DIA (Blade Mount Disc, Shaft Collar with Axial Tensioning)

- Round Bar: 50.8mm DIA (Shaft Coupling, Shaft Collar)

- Round Bar: 31.8mm DIA (Shaft, Operation Handle, Vise Handle)

- Round Bar: 8mm DIA (Pin)

- Setscrew: M8x1.25 THREAD

- Bolts and Nuts: M12x1.75 THREAD

- Threaded Rod: M30x3.5 THREAD

- Nuts: M30x3.5 THREAD

Uniform Mounting Dimensions

- Swivel Mechanism

Base Disc Mounting Rectangle Sides: 60mm x 100mm

- Vise Mechanism

Vise Mounting Rectangle Sides: 50mm x 90mm

Center-to-Center Distance Between Vise Shaft and Threaded Rod: 95mm

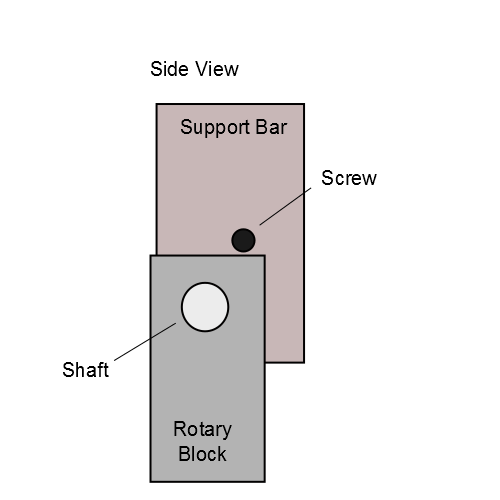

- Rotary Support Mechanism

Center-to-Center Distance Between Support Block Screws: 55mm

- Drive Mechanism

Interface Mounting Rectangle Sides: 75mm x 80mm

Hydraulic Motor Mounting Rectangle Sides: 40mm x 100mm

- Blade Guard

Center-to-Center Distance between Blade Guard Support Screws: 100mm