Cold Saw/V1 Design Rationale/Blade Rotation System: Difference between revisions

Jump to navigation

Jump to search

| Line 4: | Line 4: | ||

*The blade rotation system's axis of rotation should be perpendicular to the plane of the blade to ensure that the plane of the cut is perpendicular to the axis of rotary descent. If this is so, all else being rigid, the cut will descend through the workpiece along a perfectly vertical arc. | *The blade rotation system's axis of rotation should be perpendicular to the plane of the blade to ensure that the plane of the cut is perpendicular to the axis of rotary descent. If this is so, all else being rigid, the cut will descend through the workpiece along a perfectly vertical arc. | ||

=Feature: Fixed Blade Guard= | =Feature: Fixed Blade Guard= | ||

Revision as of 22:40, 19 June 2012

Blade Rotation System Notes

- The blade rotation system must be rigid to ensure precision

- The blade rotation system's axis of rotation should be perpendicular to the plane of the blade to ensure that the plane of the cut is perpendicular to the axis of rotary descent. If this is so, all else being rigid, the cut will descend through the workpiece along a perfectly vertical arc.

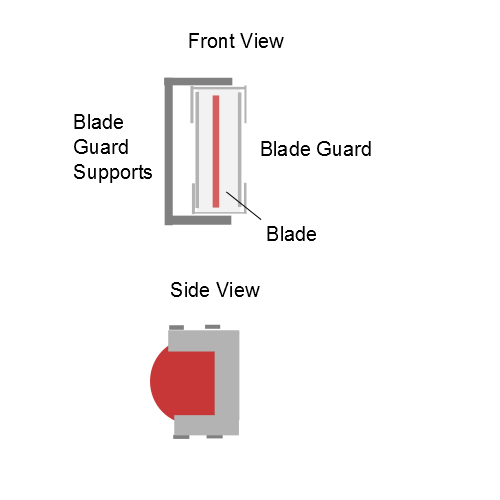

Feature: Fixed Blade Guard

- Fixed Blade Guard (to protect against unintended blade contact during operation)

The blade guard must be wide enough on one side such that the blade can be disassembled without needing to remove the blade guard.