Cold Saw/Understand: Difference between revisions

No edit summary |

|||

| Line 12: | Line 12: | ||

[[Image: ColdSawV1BasCpt.png]] | [[Image: ColdSawV1BasCpt.png]] | ||

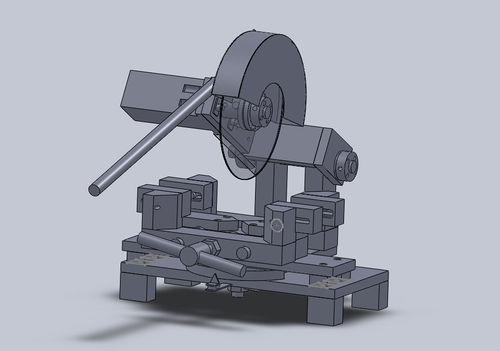

=Full Assembly Picture= | |||

[[Image: ColdSawV1Full.jpg|500px]] | |||

=Rationale= | =Rationale= | ||

Revision as of 19:19, 26 June 2012

Introduction

Simply put, the Cold Saw cuts materials.

More specifically, the Cold Saw rotates a circular blade with sharp teeth to chip away at the material being cut.

The Cold Saw is "cold" because most of the thermal energy generated during the cutting process is transferred to the chips that are cut off, instead of the blade or the remaining material. That said, the Cold Saw needs coolant to be consistently applied to the blade during operation.

Different material compositions, shapes, dimensions all determine how fast the blade should spin (rotation speed) and how quickly the blade should move into the workpiece (feed rate). If the feed rate is too high, the blade is in danger of jamming and breaking. If the feed rate is too low, the blade's durability will not be maximized.

Cold Saw blades can be resharpened many times!

Full Assembly Picture

Rationale

Should the blade move towards the workpiece, or the workpiece move toward the blade, or both?

http://opensourceecology.org/wiki/Cold_Saw/V1_Design_Rationale/Basic_Concept/Movement

Functions

Rotate the blade.

Move the blade into the material.

Angle the blade relative to the material.

Hold the material.

Objectives

Precision cuts with surface deviation of less than 0.1mm

Precision center angle locking mechanism with deviation of less than 1 degree

Precision perpendicular descent with vertical cutting plane angled within 1 degree.

Up to 45 degree cuts for at least 1" wide materials.

Clamping materials of at least 4" width.

General Notes

Precision requires rigidity.

Functional design avoids interference between mechanisms.