PowerCube6 Hydraulic Reservoir: Difference between revisions

Jump to navigation

Jump to search

Tom Griffing (talk | contribs) (Created page with "Procedure for fabricating the hydraulic reservoir. Note that the preparation of the edges for welding is critical, as the welded seams must prevent fuel leaks. Part List: Recta...") |

Tom Griffing (talk | contribs) No edit summary |

||

| (3 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

Procedure for fabricating the hydraulic reservoir. Note that the preparation of the edges for welding is critical, as the welded seams must prevent | Procedure for fabricating the hydraulic reservoir. | ||

Note that the preparation of the edges for welding is critical, as the welded seams must prevent fluid leaks. | |||

Part List: | Part List: | ||

* 1/4" x 6" x 12" - 26" Rectangular tube | |||

* [2] 1/4" x 6" x 12" Flat Steel | |||

* [2] 3/4" NPTF weld-in flange | |||

* 3/4" NPTM plastic tank breather | |||

* 1 1/2" NPTF x 3" union | |||

* Hydraulic tank thermometer and sight gauge | |||

* [2] 1/4" NPTM plug - Galvanized | |||

* [2] 3/4" NPTM plug - PVC | |||

* 1 1/2" NPTM plug - PVC | |||

* Schrader air valve | |||

* Soapy water | |||

Procedure: | |||

# Grind the 1/4" x 6" x 12" plates, rounding the corners to 1/2" radius and beveling the edges for welding. | |||

# Grind the 1/2" x 6" x 12" Tube, beveling the edges for welding. | |||

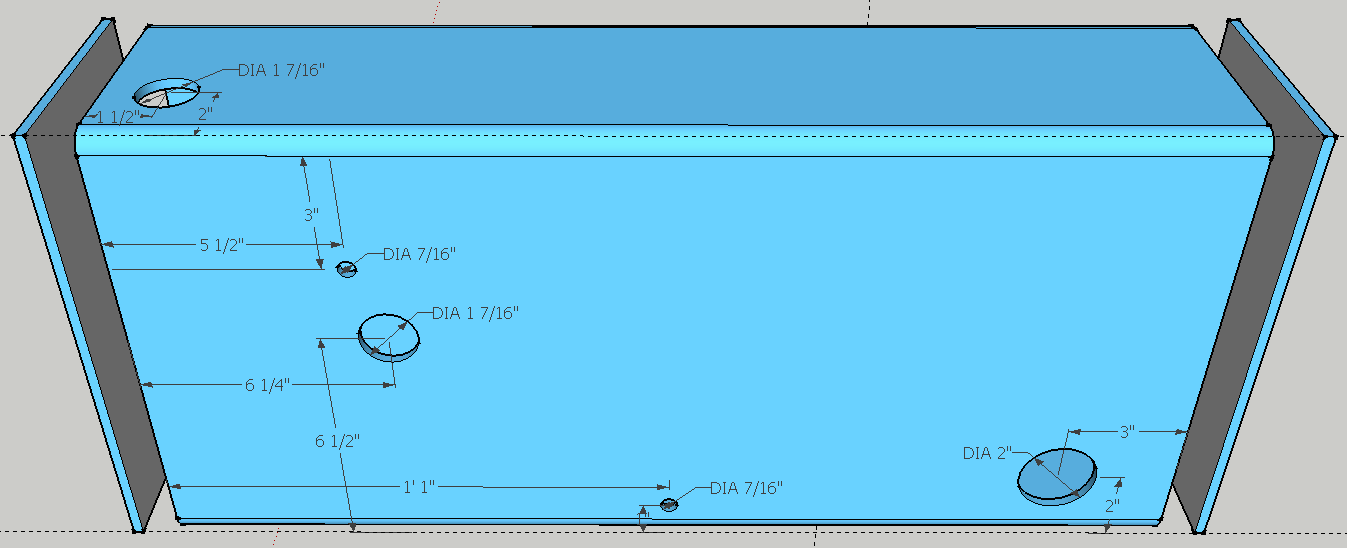

# Cut the 7/16", 1 7/16" and 2" holes in the tube as shown. The larger holes may be cut with an Oxy/Acetylene torch, then smoothed with a grinder. | |||

# Tap threads in the two smaller holes with a 1/4" NPTF tap | |||

# Weld the three flanges to the tank | |||

# Weld the "front" plate (ie: the one near the oil filter) to the end of the tube | |||

# Drill the two 1/2" holes for site gauge and securely install the site gauge | |||

# Tap the 7/16" hole for 1/4" NPTF threads, smooth the welds with the grinder. | |||

# Pressure test the tank by covering the filler neck with a plastic sheet, then securing the cap. Secure the smaller hole with a the fuel pickup and some 1/4" hose on the hose barb. Apply compressed air to the end of the rubber hose to pressurize the tank, then apply soapy water to all welds and check for bubbles. | |||

# Mark any bubbling spots with a felt-tip marker and re-weld | |||

# Re-test the tank and re-weld as necessary to stop all leaks | |||

[[image:HydraulicReservoirFab.png|600px Hydraulic Reservoir]] | |||

Latest revision as of 12:56, 22 August 2012

Procedure for fabricating the hydraulic reservoir. Note that the preparation of the edges for welding is critical, as the welded seams must prevent fluid leaks.

Part List:

- 1/4" x 6" x 12" - 26" Rectangular tube

- [2] 1/4" x 6" x 12" Flat Steel

- [2] 3/4" NPTF weld-in flange

- 3/4" NPTM plastic tank breather

- 1 1/2" NPTF x 3" union

- Hydraulic tank thermometer and sight gauge

- [2] 1/4" NPTM plug - Galvanized

- [2] 3/4" NPTM plug - PVC

- 1 1/2" NPTM plug - PVC

- Schrader air valve

- Soapy water

Procedure:

- Grind the 1/4" x 6" x 12" plates, rounding the corners to 1/2" radius and beveling the edges for welding.

- Grind the 1/2" x 6" x 12" Tube, beveling the edges for welding.

- Cut the 7/16", 1 7/16" and 2" holes in the tube as shown. The larger holes may be cut with an Oxy/Acetylene torch, then smoothed with a grinder.

- Tap threads in the two smaller holes with a 1/4" NPTF tap

- Weld the three flanges to the tank

- Weld the "front" plate (ie: the one near the oil filter) to the end of the tube

- Drill the two 1/2" holes for site gauge and securely install the site gauge

- Tap the 7/16" hole for 1/4" NPTF threads, smooth the welds with the grinder.

- Pressure test the tank by covering the filler neck with a plastic sheet, then securing the cap. Secure the smaller hole with a the fuel pickup and some 1/4" hose on the hose barb. Apply compressed air to the end of the rubber hose to pressurize the tank, then apply soapy water to all welds and check for bubbles.

- Mark any bubbling spots with a felt-tip marker and re-weld

- Re-test the tank and re-weld as necessary to stop all leaks