Briquetting machine: Difference between revisions

Huang Jack (talk | contribs) (Created page with "'''Briquetting Machine''' Briquetting machine is also called briquette maker or briquette press, which are machines that using very huge pressure to squeeze biomass material ...") |

(added pic, some minor edits) |

||

| Line 1: | Line 1: | ||

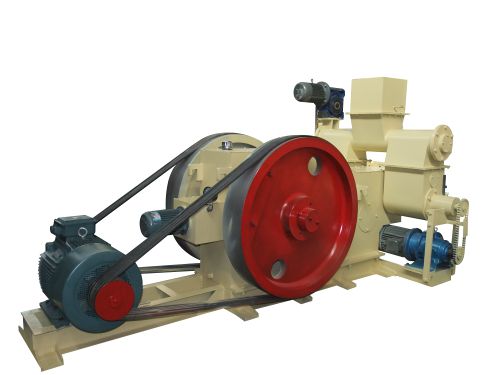

[[File:Stamping briquette maker.jpg|500px|thumb|right]] | |||

==Briquetting Machine== | |||

Briquetting machine is also called briquette maker or briquette press, which are machines that using very huge pressure to squeeze biomass material into shapes of square blocks or round sticks. Based on different working principles, there are stamping type briquetting machine, hydraulic briquetting machine and screw press briquetting machine. According to different feeding materials, there are biomass briquetting machine, metal briquetting machine and so forth. | Briquetting machine is also called briquette maker or briquette press, which are machines that using very huge pressure to squeeze biomass material into shapes of square blocks or round sticks. Based on different working principles, there are stamping type briquetting machine, hydraulic briquetting machine and screw press briquetting machine. According to different feeding materials, there are biomass briquetting machine, metal briquetting machine and so forth. | ||

==Biomass Briquette== | |||

By and large, biomass briquette are made of wood waste, such as sawdust, wood shavings and agro-waste, such as crop straws, bagasse. | By and large, biomass briquette are made of wood waste, such as sawdust, wood shavings and agro-waste, such as crop straws, bagasse. | ||

[[File:Hexagon wood briquettes.jpg| | [[File:Hexagon wood briquettes.jpg|500px|thumb|right]] | ||

==The Advantage and Usage of Biomass Briquette== | |||

As the briquettes are pressed from biomass waste by strong pressure, the size is only 1/10 of the original material. It is compact and calorific value concentrated, 40% higher in term of burning efficiency. On top of that, the briquettes are smoke and ash free when burning, which make themselves a substitute fuel resource of traditional fossil fuel, especially coal. | As the briquettes are pressed from biomass waste by strong pressure, the size is only 1/10 of the original material. It is compact and calorific value concentrated, 40% higher in term of burning efficiency. On top of that, the briquettes are smoke and ash free when burning, which make themselves a substitute fuel resource of traditional fossil fuel, especially coal. | ||

Most of biomass briquettes are produced for heating in both civil and industrial scale. Some hardwood briquettes are further processed into charcoal briquettes which are used for grills. | Most of biomass briquettes are produced for heating in both civil and industrial scale. Some hardwood briquettes are further processed into charcoal briquettes which are used for grills. | ||

[[File:FuelBriquette Maker.jpg|500px|thumb|right|Fuel briquette maker (Foundation of Sustainable Technology, Nepal).]] | |||

External Links: | ==External Links== | ||

* [http://www.biofuelmachines.com/Briquetting-Machine.html briquetting Machine Review] | |||

[ | [[Category:Energy]] | ||

[[Category:Biofuel]] | |||

Latest revision as of 19:28, 28 August 2016

Briquetting Machine

Briquetting machine is also called briquette maker or briquette press, which are machines that using very huge pressure to squeeze biomass material into shapes of square blocks or round sticks. Based on different working principles, there are stamping type briquetting machine, hydraulic briquetting machine and screw press briquetting machine. According to different feeding materials, there are biomass briquetting machine, metal briquetting machine and so forth.

Biomass Briquette

By and large, biomass briquette are made of wood waste, such as sawdust, wood shavings and agro-waste, such as crop straws, bagasse.

The Advantage and Usage of Biomass Briquette

As the briquettes are pressed from biomass waste by strong pressure, the size is only 1/10 of the original material. It is compact and calorific value concentrated, 40% higher in term of burning efficiency. On top of that, the briquettes are smoke and ash free when burning, which make themselves a substitute fuel resource of traditional fossil fuel, especially coal. Most of biomass briquettes are produced for heating in both civil and industrial scale. Some hardwood briquettes are further processed into charcoal briquettes which are used for grills.