Sawmill - Design Calculations: Difference between revisions

No edit summary |

No edit summary |

||

| (One intermediate revision by the same user not shown) | |||

| Line 1: | Line 1: | ||

==Available Power== | |||

*Review of LifeTrac hydraulic power calculations - [[LifeTrac#Calculations]] - shows that we have total 29 gpm available at 3300 PSI, or a lower flow at 3600 PSI. | |||

*Hydraulic power is defined as Flow x Pressure. The hydraulic power supplied by a pump: P in [bar] and Q in [lit/min] => (P x Q) / 600 [kW]. Ex. Pump delivers 180 [lit/min] and the P equals 250 [bar] => Pump power output = (180 x 250) / 600 = 75 [kW]. 75000W / 745.7 = 100.58hp | |||

**LifeTrac has 91 l/min available from the auxiliary hydraulics, and 228 bar - 91x228/600/.746 = about 46 hp. | |||

***24 gallons/minute = 91 liters/minute (of 29 gpm total [[LifeTrac]] power, 5 is diverted into tractor steering) | |||

***1 bar = 14.5 psi, 3300 PSI = 228 Bar | |||

==Power Distribution Between 2 Sets of Blades== | |||

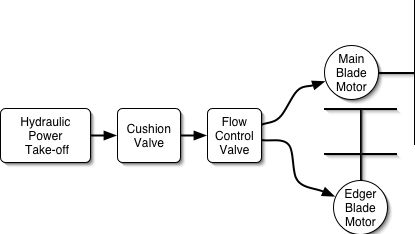

The sawmill has 2 sets of blades: the main blade and the edger blades - see 3d picture - [[#3D_CAD_-_Using_Blender]]. Hydraulic power must be distributed to both sets. One motor powers the 2 edger blades, and another motor powers the main blade. Power - or hydraulic fluid flow - must be distributed to both sets of motors to accommodate various cutting scenarios: | |||

*Assume that main blade is 20 inches in diameter, and edger blades are 10" | |||

*Square lumber profiles, such as 2x2s and 4x4s (size in inches) | |||

*Rectangular lumber profiles - such as 2x4s, 4x8s, up to 1x9s | |||

*The case where square profiles are cut requires one cut by the main blade, and equivalent cuts by the edger blades. Since there are 2 edger blades, this requires the condition where the edger blades require twice as much power as the main blade. The power distribution strategy and motor sizing should allow for this. Power ratio of main (Pm) to edger (Pe) blades: '''Pm/Pe = 1/2''' | |||

*In the extreme opposite case, such as when cutting 1x10, the power ratio is '''Pm/Pe = 5''' | |||

*The middle case exists for 2x4s, 4x8x - where '''Pm/Pe = 1''' | |||

===Hydraulics Design for 2 Sets of Blades=== | |||

The point is that flow control must exist where the amount of power that goes to each blade can be varied. Power is controlled by fluid flow rate - or a ''flow control valve'' in practice: | |||

[[Image:dimensionalhydraulics.jpg]] | |||

Would this valve from Surpluscenter [http://surpluscenter.com/item.asp?UID=2009012117064247&item=9-4169-12&catname=hydraulic] do?: | |||

[[Image:dimensionalfcv.jpg]] | |||

===Hydraulic Motors=== | |||

====Edger Blades - 12"==== | |||

*http://www.surpluscenter.com/item.asp?UID=2009020615535006&item=9-4769&catname=hydraulic | |||

[[Image:hydmotoredger.jpg]] | |||

====Main Blade - 20"==== | |||

*http://www.surpluscenter.com/item.asp?UID=2009020615535006&item=9-7073-150&catname=hydraulic | |||

[[Image:hydmotormain.jpg]] | |||

> Hydraulic power is defined as Flow x Pressure. The hydraulic power | > Hydraulic power is defined as Flow x Pressure. The hydraulic power | ||

| Line 10: | Line 56: | ||

LifeTrac has 95 l/min available from the auxiliary hydraulics, and 250 bar - | LifeTrac has 95 l/min available from the auxiliary hydraulics, and 250 bar - | ||

95x250/600/.746 = about 52 hp. | 95x250/600/.746 = about 52 hp. | ||

[[Category:Sawmill]] | |||

Latest revision as of 01:07, 29 May 2009

Available Power

- Review of LifeTrac hydraulic power calculations - LifeTrac#Calculations - shows that we have total 29 gpm available at 3300 PSI, or a lower flow at 3600 PSI.

- Hydraulic power is defined as Flow x Pressure. The hydraulic power supplied by a pump: P in [bar] and Q in [lit/min] => (P x Q) / 600 [kW]. Ex. Pump delivers 180 [lit/min] and the P equals 250 [bar] => Pump power output = (180 x 250) / 600 = 75 [kW]. 75000W / 745.7 = 100.58hp

- LifeTrac has 91 l/min available from the auxiliary hydraulics, and 228 bar - 91x228/600/.746 = about 46 hp.

- 24 gallons/minute = 91 liters/minute (of 29 gpm total LifeTrac power, 5 is diverted into tractor steering)

- 1 bar = 14.5 psi, 3300 PSI = 228 Bar

- LifeTrac has 91 l/min available from the auxiliary hydraulics, and 228 bar - 91x228/600/.746 = about 46 hp.

Power Distribution Between 2 Sets of Blades

The sawmill has 2 sets of blades: the main blade and the edger blades - see 3d picture - #3D_CAD_-_Using_Blender. Hydraulic power must be distributed to both sets. One motor powers the 2 edger blades, and another motor powers the main blade. Power - or hydraulic fluid flow - must be distributed to both sets of motors to accommodate various cutting scenarios:

- Assume that main blade is 20 inches in diameter, and edger blades are 10"

- Square lumber profiles, such as 2x2s and 4x4s (size in inches)

- Rectangular lumber profiles - such as 2x4s, 4x8s, up to 1x9s

- The case where square profiles are cut requires one cut by the main blade, and equivalent cuts by the edger blades. Since there are 2 edger blades, this requires the condition where the edger blades require twice as much power as the main blade. The power distribution strategy and motor sizing should allow for this. Power ratio of main (Pm) to edger (Pe) blades: Pm/Pe = 1/2

- In the extreme opposite case, such as when cutting 1x10, the power ratio is Pm/Pe = 5

- The middle case exists for 2x4s, 4x8x - where Pm/Pe = 1

Hydraulics Design for 2 Sets of Blades

The point is that flow control must exist where the amount of power that goes to each blade can be varied. Power is controlled by fluid flow rate - or a flow control valve in practice:

Would this valve from Surpluscenter [1] do?:

Hydraulic Motors

Edger Blades - 12"

Main Blade - 20"

> Hydraulic power is defined as Flow x Pressure. The hydraulic power

> supplied by a pump: P in [bar] and Q in [lit/min] => (P x Q) / 600 [kW].

> Ex. Pump delivers 180 [lit/min] and the P equals 250 [bar] => Pump power

> output = (180 x 250) / 600 = 75 [kW]. 75000W / 745.7 = 100.58hp

LifeTrac has 95 l/min available from the auxiliary hydraulics, and 250 bar - 95x250/600/.746 = about 52 hp.