CEB Press/Manufacturing Instructions/Hopper mounting plate: Difference between revisions

Jump to navigation

Jump to search

(redid it) |

No edit summary |

||

| (9 intermediate revisions by 4 users not shown) | |||

| Line 1: | Line 1: | ||

[[Image:hopper-mounting-plate.jpg|thumb]] | |||

<html><iframe src="http://sketchup.google.com/3dwarehouse/mini?mid=1951330c482561411211da1f85706ccd&etyp=sw&width=400&height=300" frameborder="0" scrolling="no" marginheight="0" marginwidth="0" width="400" height="300"></iframe> | |||

</html> | |||

=Tools= | |||

*Hole punch with 13/16" Die | *Hole punch with 13/16" Die | ||

*Welder | *Welder | ||

*Angle Grinder | |||

=Materials= | |||

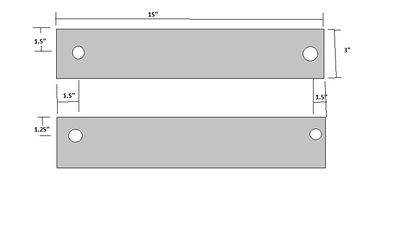

*[2] Steel Plate 1/2” x 3” x 11.25” | |||

*[2] Steel Plate 1/2” x 3” x 15” | |||

=Fabrication Steps= | |||

*Punch the 13/16" holes in the 15" pieces. | |||

[[Image:hoppermountholes.jpg|400px|The hole locations]] | |||

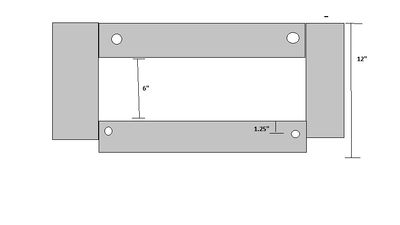

*Weld the pieces together on both sides (upper and lower), ensuring everything is square. | |||

[[Image:hoppermountweld.jpg|400px|How to prep the plate for welding]] | |||

*Grind one side (upper or lower) smooth to facilitate installation | |||

Latest revision as of 04:45, 23 December 2011

Tools

- Hole punch with 13/16" Die

- Welder

- Angle Grinder

Materials

- [2] Steel Plate 1/2” x 3” x 11.25”

- [2] Steel Plate 1/2” x 3” x 15”

Fabrication Steps

- Punch the 13/16" holes in the 15" pieces.

- Weld the pieces together on both sides (upper and lower), ensuring everything is square.

- Grind one side (upper or lower) smooth to facilitate installation