PSoC Torch Height Sensing: Difference between revisions

| Line 22: | Line 22: | ||

However the following technical issues need to be explored: | However the following technical issues need to be explored: | ||

#. Is the sensor adequately protected against plasma noise damage? | |||

#. How should the system reject long-term (time, temperature, etc.) drift? | |||

#. Despite using shielded (coax), there is still some sensitivity to objects near the cable and circuit board. | |||

#. How will the system respond to sensing near the edge of a workpiece (where only half of the ring is over the work)? An informal check showed significant signal loss. | |||

Revision as of 01:10, 22 July 2013

Cypress PSoC4 Pioneer Board for Capacitive Torch Height Sensing

We are evaluating whether this board can provide operating height sensing for an oxyfuel torch and initial height sensing for a plasma torch. This is an important funtion required in the CNC Torch Table.

The PSoc4 ("Programmable System on a Chip") is a small ARM microcontroller with flexible peripherals. One of the peripheral functions is Cypress' "CapSense" capacitive touch sensing. A relevant demo project is here.

ChuckH testing

21 July 2013

We would like to place the circuit board in a shielded enclosure a foot or so from the torch itself, especially in the case of plasma torch application. Therefore I tried connecting the sensing electrode through about 2ft of coaxial cable. I used "CATV" coax (used with cable TV and antennas) because it is a foam core, low-capacitance cable. The PSoC chip supports "driven shield" so I used it. There are two subtypes of driven shield, , it is not yet clear which is most appropriate.

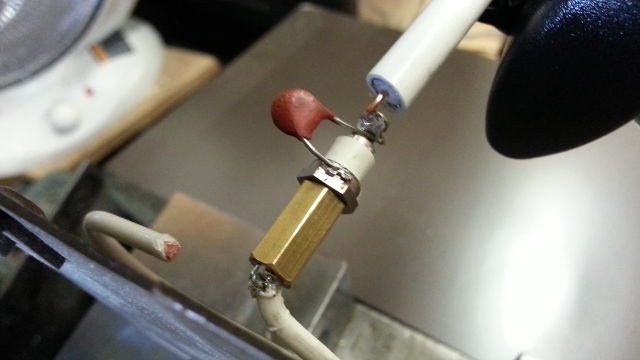

To help protect the CapSense input pin from noise spikes (specifically a concern about plasma torch RF noise damaging the chip) I placed a 12pf capacitor in series with the sensing electrode. I made a ring shape out of insulated 14AWG solid house wiring:

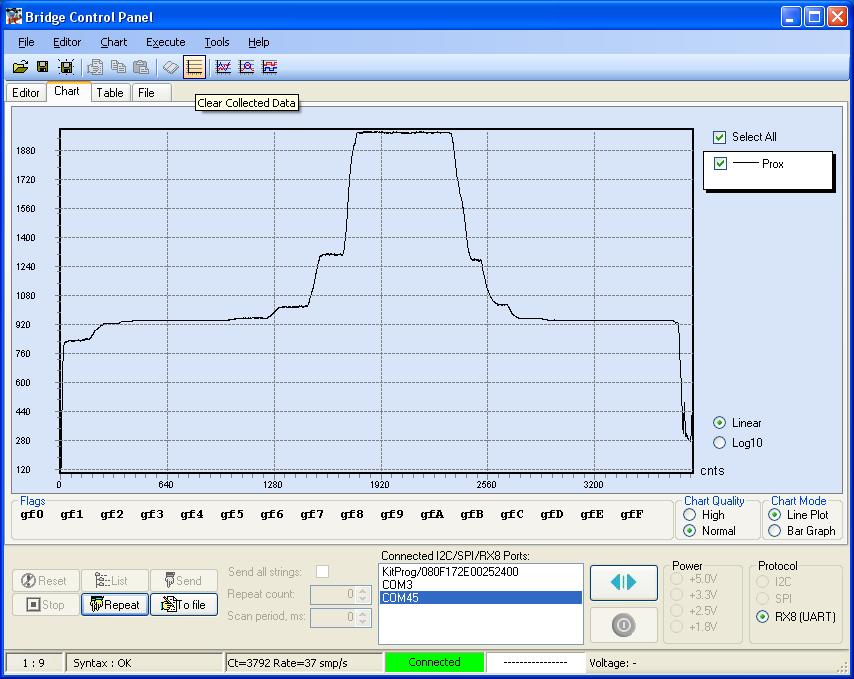

Initial tests show plenty of signal (the steps in this staircase are 0.050 inch movements):

However the following technical issues need to be explored:

- . Is the sensor adequately protected against plasma noise damage?

- . How should the system reject long-term (time, temperature, etc.) drift?

- . Despite using shielded (coax), there is still some sensitivity to objects near the cable and circuit board.

- . How will the system respond to sensing near the edge of a workpiece (where only half of the ring is over the work)? An informal check showed significant signal loss.