Lathe Build: Difference between revisions

No edit summary |

|||

| Line 1: | Line 1: | ||

=Introduction= | |||

Read this beautiful introduction on the practical aspects of a lathe in this introduction by a master of documentation, Chris Palmer - [http://hydraraptor.blogspot.com/2008/11/lathe-accesories.html] | |||

[[Image:latheintro.gif]] | |||

=Auger= | =Auger= | ||

Revision as of 17:13, 23 November 2009

Introduction

Read this beautiful introduction on the practical aspects of a lathe in this introduction by a master of documentation, Chris Palmer - [1]

Auger

Ben,

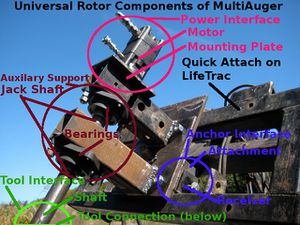

So here's my plan right now. Use a hydrauilic fixture with 20 hp that can be fixed to a table readily. This is what I have already on LifeTrac - a stiff auger mechanism:

Bill of Materials

Here is the bill of materials:

Lathe

Is it possible to convert the auger to a lathe? Sure. Take a chuck from here.

Add a slide from Enco. See review

Spec

What are the needs?

- Basic applications are couplers, hydraulic valve stems, and steam engine cylinders and pistons. Basic shortbed work on small workpieces. To be scaled up to a 2000 lb xy slide down the road for more efficient turning, with modifications as we go along.

- Length, diameter of object? 1 foot long up to 12 inch pipe

- Tolerances, including surface finish? 25 micron

- Manual or CNC? Manual at first, retrofit later.

- Material to be turned? Mild steel and aluminum.

- RPM range? 0-700 RPM

Danger

20HP at low rpm involves HUGE forces. This is going to be seriously dangerous because many of the possible failures would be catastrophic and faster than a human operator can react. Much smaller lathes cause fatal accidents from time to time. Breakage of the tool support or failure of the workholding would quite likely lead to big bits of metal flying about. Extreme caution is justified.

The proposed XY table is not intended to support anywhere near the max load that the hydraulics can apply. Most cast iron will fail fast (shatter).

A much smaller version may be a rewarding use of time to prove the design at reduced scale, cost, risk of failure, and danger of fatal or crippling injury.

Comments

- The entire system is non-optimized. It is a generalized system that optimized interchangeability of parts and multipurpose performance, not specific performance. The critical distinction is sufficiency vs. optimization. Performance can be optimized by further interchangeability. This is not a finished product, but an item that works for intended applications of milling motor couplers and boring steam engine cylinders.

- 20HP is max. It can be run from 1-20 hp.A 20 HP accident is no more fatal than a 1 HP and accident when it comes to machine vs. delicate human.

- XY table is absolutely too weak, but it is sufficient and cheap. Other suggestions are welcome.

- Marcin has significant experience regarding failure modes and behavior characteristics of hyraulics. Not an issue.

Materials, Rigidity

Pro lathes are usually made of the fewest thickest possible pieces of cast iron, for rigidity and damping. If mild steel box and sheet, bolted or welded, was good enough then there would probably be examples out there (If it's easy and cheaper and the Chinese won't do it then it probably doesn't work). There are substantial risks that the lathe will work poorly or not at all unless it is small and made of very thick stock. If any machine tool is insufficiently rigid then the cutting edge chatters on the work piece, giving a bad finish, rapid heating of the tool, and rapid tool failure. Also, cutting forces cause the machine to elastically distort, quickly introducing very large errors.

Without defining the spec, it is difficult to design. Materials for machine tool frames include

- Aluminium alloy, on small cheap low precision or soft material tools

- Cast Iron, on most machines. Well proven.

- Synthetic or real Granite, on super precision moderate mechanical load machinery

Synthetic granite is made from ~80% granite powder with an epoxy binder, and has ~9x better damping than cast iron but much lower tensile strength. (I'd like to experiment with machine tools made from a synthetic granite modified with chopped strand carbon fibre, but that's an unproven material. Leo.dearden)

Synthetic Granite

- What are costs of raw materials?

- Where do we get them?

Cross Slide

- What are options for an off-shelf cross slide?

- What are accuracy limits of simple cross slides made from cold rolled steel, 3/4 inch fine nuts and bolts, where nuts are pretensioned to minimize backlash? Is this a simple, robust solution that can reduce backlash to 25 microns?

- Are there any good DIY solutions for precision cross slides?