Drill Press: Difference between revisions

Jump to navigation

Jump to search

Marie.Byleen (talk | contribs) No edit summary |

No edit summary |

||

| Line 1: | Line 1: | ||

{{ToolTemplate|ToolName=Press Forge}} | |||

[[Category:Drill Press]] | [[Category:Drill Press]] | ||

Revision as of 07:30, 28 July 2011

| Press Forge | ||

|---|---|---|

| Home | Research & Development | Bill of Materials | Manufacturing Instructions | User's Manual | User Reviews |

| |

See Open Pario to download design file - http://openpario.mime.oregonstate.edu/projects/drillpress/documents

Bill of Materials

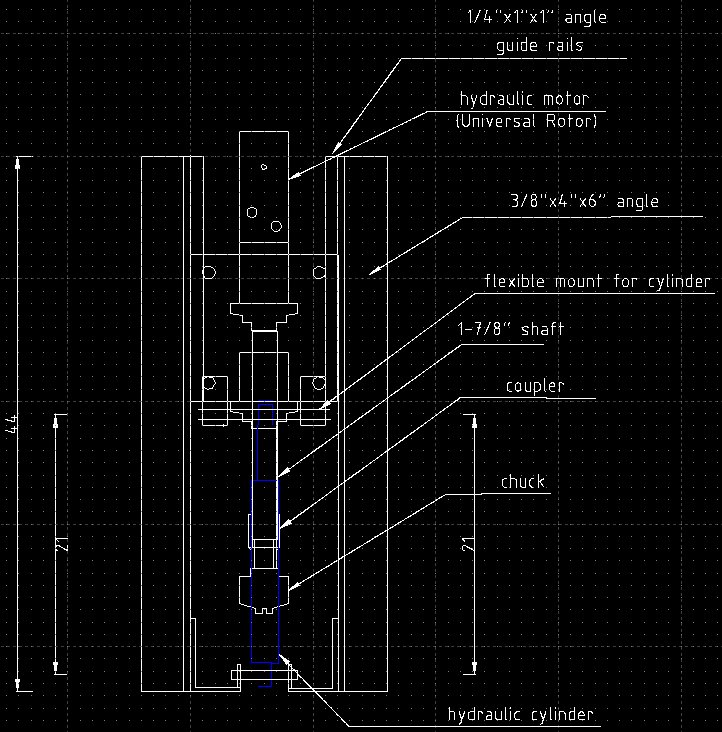

- Universal Rotor (Factor e Farm)

- Small lathe chuck (Factor e Farm)

- 1.5"x14"x1" hydraulic cylinder (Factor e Farm)

- Coupler - to go from 1-7/8 shaft to 1-1/4" shaft. 2" long on wider side, 1" long on narrower side

- [2] 3/8"x4"x6" angle, 44" long - verticals

- [4] 1/4"x1" angle, 20" long - rails for holding universal rotor to prevent it from twisting

- [2] 3/8"x4"x6" angle, 12" long

- [1] 3/4" threaded rod, 8"; [4] nuts - for top-facing end of cylinder

- [1] 3/4" threaded rod, 6"; [4] nuts - for bottom-facing end of cylinder

- [2] 1/4"x2" angle, 4" long - mounts for top-facing end of cylinder

- [2] 1/4"x2" angle, 2" long - mounts for bottom-facing end of cylinder

- [4] 1/2"x3"x15" bar - for table clamps

- [2] 1/2"x3"x7" bar - for table clamps

- [4] 1"x4" bolts - for table clamps

- [4] 1" nuts - for table clamps

Total: $150 in metal from local fab shop

Plus base:

- [2] 6"x7/8" u-channel, 3 feet long ($56)

- [2] 1/4"x2" angle, 2 foot long ($12)

Total budget: about $200 for structure, excluding chuck and Universal Rotor

Hydraulics

Conceptual design of the hydraulics for the drill press: