Talk:CEB Press Development: Difference between revisions

(Created page with "Designed collaboratively. Factor e Farm team did the builds. Sam Rose took care of funding. Funded by the crowd - Potential buyers, potential makers, potential entrepren...") |

No edit summary |

||

| Line 1: | Line 1: | ||

'''Messy information from around the wiki that can be presented here''' | |||

---- | ---- | ||

| Line 22: | Line 7: | ||

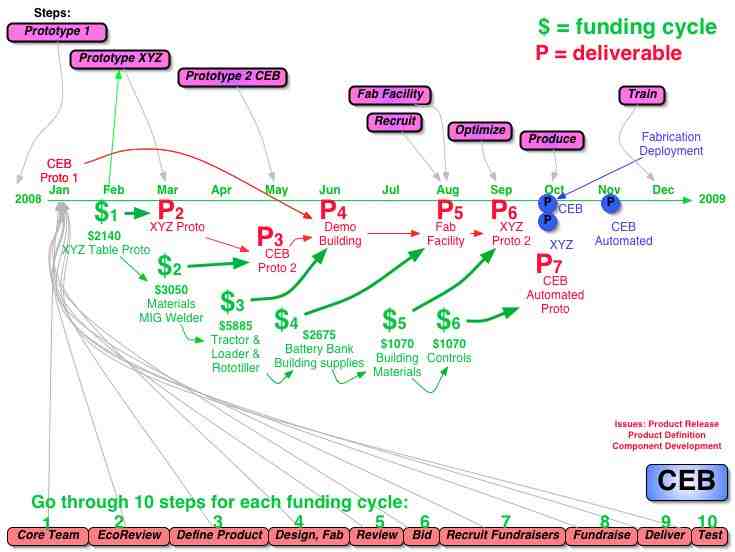

This timeline shows the ''development cycles'' on top, along with the corresponding ''funding cycles'' and ''deliverables'' in green and red. For each development cycle, we adapt a 10-step procedure, whose steps are shown at the bottom of the diagram. | This timeline shows the ''development cycles'' on top, along with the corresponding ''funding cycles'' and ''deliverables'' in green and red. For each development cycle, we adapt a 10-step procedure, whose steps are shown at the bottom of the diagram. | ||

In short, the development process cycles through two prototypes of the CEB machine itself, and two prototypes of an XYZ, computer controlled torch table (see [http://www.torchmate.com/industrial/index.htm professional version] and [http://openfarmtech.org/index.php?title=Torch_Table open source version]). The torch table will be used to automate the fabrication of the CEB machine, reducing fabrication time by an estimated 20 hours, and thus, also reducing the cost of the final product. | |||

The development timeline also includes building actual structures to test the quality of the blocks and durability and ease of use of the press. Moreover, we will build a production facility for the CEB machines, and develop an open source business model to disseminate production of these machines to other areas of the world. | |||

---- | ---- | ||

Revision as of 22:16, 25 February 2011

Messy information from around the wiki that can be presented here

This timeline shows the development cycles on top, along with the corresponding funding cycles and deliverables in green and red. For each development cycle, we adapt a 10-step procedure, whose steps are shown at the bottom of the diagram.

In short, the development process cycles through two prototypes of the CEB machine itself, and two prototypes of an XYZ, computer controlled torch table (see professional version and open source version). The torch table will be used to automate the fabrication of the CEB machine, reducing fabrication time by an estimated 20 hours, and thus, also reducing the cost of the final product.

The development timeline also includes building actual structures to test the quality of the blocks and durability and ease of use of the press. Moreover, we will build a production facility for the CEB machines, and develop an open source business model to disseminate production of these machines to other areas of the world.