Pipe insulation: Difference between revisions

No edit summary |

No edit summary |

||

| Line 1: | Line 1: | ||

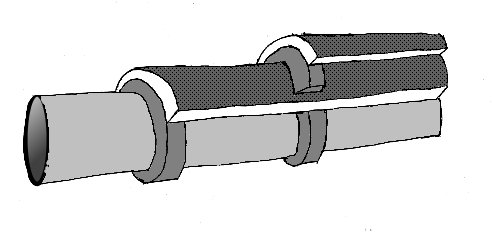

Ceramic cloth is being used for high temperature insulation of pipes in this system. The effectiveness of this cloth can be greatly increased by using airgaps with reflective barriers. here, thin strips of ceramic cloth leave air gaps, and then the pipe is wrapped with a full layer of ceramic cloth with aluminum foil (or a more resilient reflecting film) on the underside. Small tacks hold the layers of cloth to the cloth spacers below them. | Ceramic cloth is being used for high temperature insulation of pipes in this system. The effectiveness of this cloth can be greatly increased by using airgaps with reflective barriers. here, thin strips of ceramic cloth leave air gaps, and then the pipe is wrapped with a full layer of ceramic cloth with aluminum foil (or a more resilient reflecting film) on the underside. Small tacks hold the layers of cloth to the cloth spacers below them. | ||

In this picture of a two layer insulated pipe, the pipe is light grey, the strips of cloth used for spacers are dark grey, and the sheets of cloth are white and thacthed black/grey. The aluminum foil (not shown) is on the underside of the sheets of cloth inorder to reflect radiated heat back. | In this picture of a two layer insulated pipe, the pipe is light grey, the strips of cloth used for spacers are dark grey, and the sheets of cloth are white and thacthed black/grey. The aluminum foil (not shown) is on the underside of the sheets of cloth inorder to reflect radiated heat back. Here, the layers are cut away so that the structure is more visible. | ||

[[Image:pipeinsulation.jpg]] | [[Image:pipeinsulation.jpg]] | ||

A similar arrangement (covering only 180 degrees of the pipe) could be used for the absorber tubes. | A similar arrangement (covering only 180 degrees of the pipe) could be used for the absorber tubes. | ||

Revision as of 22:15, 23 June 2008

Ceramic cloth is being used for high temperature insulation of pipes in this system. The effectiveness of this cloth can be greatly increased by using airgaps with reflective barriers. here, thin strips of ceramic cloth leave air gaps, and then the pipe is wrapped with a full layer of ceramic cloth with aluminum foil (or a more resilient reflecting film) on the underside. Small tacks hold the layers of cloth to the cloth spacers below them.

In this picture of a two layer insulated pipe, the pipe is light grey, the strips of cloth used for spacers are dark grey, and the sheets of cloth are white and thacthed black/grey. The aluminum foil (not shown) is on the underside of the sheets of cloth inorder to reflect radiated heat back. Here, the layers are cut away so that the structure is more visible.

A similar arrangement (covering only 180 degrees of the pipe) could be used for the absorber tubes.