Rapid Prototyping: Difference between revisions

No edit summary |

|||

| Line 27: | Line 27: | ||

The research project in this area involves the fabrication and integration of the individual components for this project. Factor e Farm is willing to provide materials funding for students interested in taking this on as a development project - please [mailto:joseph.dolittle@gmail.com contact us]. | The research project in this area involves the fabrication and integration of the individual components for this project. Factor e Farm is willing to provide materials funding for students interested in taking this on as a development project - please [mailto:joseph.dolittle@gmail.com contact us]. | ||

[[Category: | [[Category:Research]] | ||

Revision as of 09:10, 3 May 2011

Introduction

There is a significant set of open source technologies that enables rapid prototyping to take place in local workshops. Combine 3D printing with low-cost metal casting, and follow with machining using a computer controlled Multimachine, and you have the capacity to make rapid prototypes and products from metal.

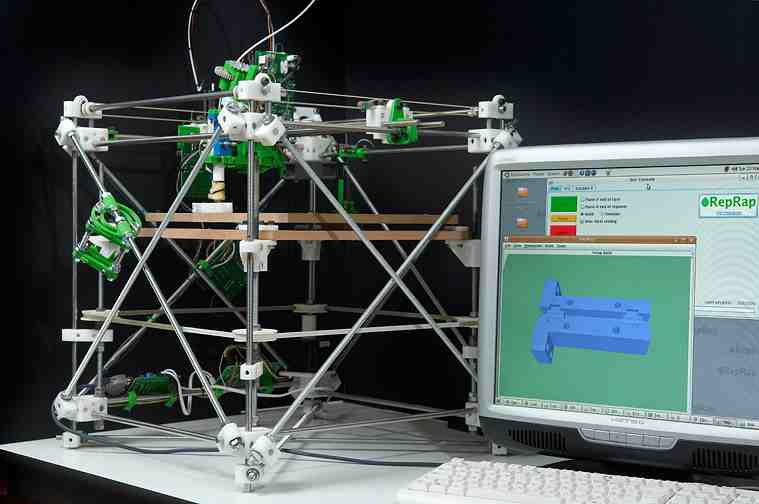

- RepRap - open source 3D Printer - has just achieved self-replication

- Small-scale metal casting technology is readily available.

- In particular, a waste oil burner such as the Babington burner may be utilized as the heat source.

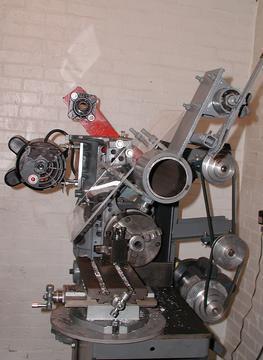

- Multimachine - an open source multipurpose machining tool is available.

The interesting part is that the budget is $500 for RepRap, $200 for the casting equipment, and $1500 for a Multimachine with CNC control added. Using available knowhow, this can be put together in a small workshop for a total of about $2200 - for full, computer controlled rapid fabrication. Designs may be downloaded from the internet, and local production can take place based on global design.

Such a project is interesting from the standpoint of localized production in the context of the global economy - for creating significant wealth in local economies.

Research Needs

The research project in this area involves the fabrication and integration of the individual components for this project. Factor e Farm is willing to provide materials funding for students interested in taking this on as a development project - please contact us.