CEB Press/Manufacturing Instructions/Frame with main cylinder: Difference between revisions

Jump to navigation

Jump to search

William Neal (talk | contribs) |

William Neal (talk | contribs) mNo edit summary |

||

| Line 17: | Line 17: | ||

[[Image:channel.jpg|thumb|Step 1. Torch or cold-cut channel to size]] | [[Image:channel.jpg|thumb|Step 1. Torch or cold-cut channel to size]] | ||

Cut the following pieces out of the 6 inch heavy (7/16") u-channel steel: | Cut the following pieces out of the 6 inch heavy (7/16") u-channel steel: | ||

A - 2 pieces, 41 1/2" | |||

B - 2 pieces, 28 3/4" | |||

C - 4 pieces, 20 3/4" | |||

D - 2 pieces, 9" | |||

Cut the following pieces out of 1/4X2"X4" angle steel: | Cut the following pieces out of 1/4X2"X4" angle steel: | ||

E - 2 pieces 20 3/4" | |||

Cut the following pieces out of 1/4" sheet steel: | Cut the following pieces out of 1/4" sheet steel: | ||

*2 pieces 10”x18” (bent (90 degrees???) 1.5” off the edge the long way) | *2 pieces 10”x18” (bent (90 degrees???) 1.5” off the edge the long way) | ||

| Line 29: | Line 29: | ||

[[Image:punchedholes.jpg|thumb|Step 2]] | [[Image:punchedholes.jpg|thumb|Step 2]] | ||

*Punch four holes in each of the | *Punch four holes in each of the 28 3/4" pieces such that they are 19.4" apart on the long axis and 4"(?not sure) apart on the short axis. They should form a centred rectangle parallel to each of the 26" pieces. | ||

*Punch four holes in each of the | *Punch four holes in each of the 20 3/4" pieces such that they are 19.4" apart on the long axis and 4"(?not sure) apart on the short axis. They should form a centred rectangle parallel to each of the 18" pieces. | ||

*Punch holes, 1" from the tip of the edge, in the edges of | *Punch holes, 1" from the tip of the edge, in the edges of 41 1/2" upright pieces at the following locations: 1", 5", 36.5", 40.5"(more to follow) | ||

===Step 3: Bolt pieces together=== | ===Step 3: Bolt pieces together=== | ||

Revision as of 15:31, 30 June 2011

Main > Housing and construction > CEB Press > CEB press building instructions

Tools Required

- torch

- hole punch

Materials Required

- 6 inch heavy (7/16") u-channel - ( 20 ft )

- bolts

- 3”x3”x1/2” (8) (cylinder mounts for both cylinders)

- 1” shaft, 6” long (main cylinder mount)

- 5 X 8 3000PSI Welded Cross-Tube Hydraulic Cylinder Buy

Fabrication Steps

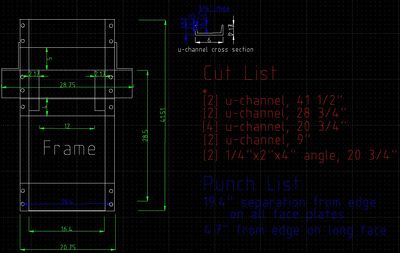

Step 1: Cut pieces

Cut the following pieces out of the 6 inch heavy (7/16") u-channel steel: A - 2 pieces, 41 1/2" B - 2 pieces, 28 3/4" C - 4 pieces, 20 3/4" D - 2 pieces, 9" Cut the following pieces out of 1/4X2"X4" angle steel: E - 2 pieces 20 3/4" Cut the following pieces out of 1/4" sheet steel:

- 2 pieces 10”x18” (bent (90 degrees???) 1.5” off the edge the long way)

Step 2: Punch holes

- Punch four holes in each of the 28 3/4" pieces such that they are 19.4" apart on the long axis and 4"(?not sure) apart on the short axis. They should form a centred rectangle parallel to each of the 26" pieces.

- Punch four holes in each of the 20 3/4" pieces such that they are 19.4" apart on the long axis and 4"(?not sure) apart on the short axis. They should form a centred rectangle parallel to each of the 18" pieces.

- Punch holes, 1" from the tip of the edge, in the edges of 41 1/2" upright pieces at the following locations: 1", 5", 36.5", 40.5"(more to follow)

Step 3: Bolt pieces together

Step 4: Prepare Hydraulic Cylinder

Diagram and video explantion

This diagram shows the pieces needed for the frame. Click to enlarge: