Anthony Repetto/Concept Log: Difference between revisions

| Line 98: | Line 98: | ||

=='''Useful Entropy'''== | =='''Useful Entropy'''== | ||

I should put some information here, before folks get suspicious. Thermodynamics talks about Work - the movement of energy needed to change something. Work isn't energy. It's the movement of hot to cold, the release of tension or pressure, positioned in such a way that it separates hot and cold, or applies tension or pressure, somewhere else. You take the gradient between one pair of objects, (hot/cold, in a steam engine) and move that gradient to another pair (relative motion, for the same case). When we do this 'irreversibly', that means we lost a bit of the gradient. The difference in temperature or pressure you start with is greater than the difference you can create (in a steam engine - to - refrigeration set-up, for example). That's entropy. Stuff leaked, got hot, and wore down - and we can't use it any more, unless we exert more energy. So, we call the part of the gradient that we preserve, 'useful work'. But, is that the only thing in this we can find useful? Now, maybe you're curious. ;) | |||

=Possibilities= | =Possibilities= | ||

Revision as of 02:28, 16 July 2011

Concept Summaries

last updated: 14. July, 2011

Here are a few concepts OSE may find useful. I'll continue to update, and link to detailed sub-pages as I draft them. This page is the reference point for work I find interesting; each topic has a summary of its design features, and the issues it addresses. I'd love to develop simple visualizations for these ideas, and others; text is limited.

Project-Specific Considerations

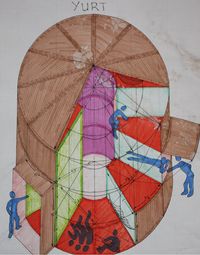

Yurt

The intention is to provide a quick start-up dwelling for new GVCS sites; same-day housing, while you wait for the CEB machine to bash bricks.

For disaster relief, slums and outliers in the developing world, and migrant/start-up labor sites: a simple, sturdy tent structure, encircling rings of 'cubbies', layered like a cake. (Picture a stack of pineapple rings.) Rough tent dimensions: 20' (6m) wide, 12' (3 2/3m) high walls, 15' (4 1/2m) apex.

The interior cubby rings are broken into 12 radial segments; one segment is the entry way, 11 are private tents. The center is open, 6' (1 4/5m) wide, with laddering on the frame to ascend into third-tier cubbies, or to access 'attic' storage. Each cubby is 4' (1 1/5m) tall, 1 1/2' (1/2m) wide at its interior entry, 7' (2 1/6m) long, and 5 1/4' (1 3/5m) wide along the exterior wall. Materials are: steel framing (for 34 people, plus personal supplies, or up to 100 people as a disaster shelter; mother, father, & small child per cubby - over 20,000lb (10 tonne) support necessary); exterior skirt (a single weather-resistant sheet, lying over the frame); and individual cubby tents (edges threaded with support chords, which attach to frame - at least 600lb (270kg) support necessary).

When taken apart, its compact form can be stacked in a 20' (6m) wide cylinder, which could double as a water tower, silo, or fuel tank, and, if 15' (4 1/2m) tall, the canister could hold as many as 10 such yurts. (Immediate shelter for up to 1,000 people, or 340 folks as private dwellings.) Include tools, emergency supplies, etc. for a village-in-a-box.

Trencher

There are already a wide variety of earth moving machines. Bucket wheels work quickly, but they're huge, expensive, and require expertise. Scrapers remove loose top soil, but have to haul their loads away, reducing their time-use efficiency. I wouldn't bother with an excavator. If we could build a smaller LifeTrac attachment, irrigation canals would be within reach. The primary limitations to existing designs are fuel and capital efficiency. Considering the optimal case, where you only account for the work of separating and lifting the soil, a gallon of gasoline should be able to dig a huge canal. But, existing machines breeze through fuel, and have either unacceptable lag times, requiring more operator hours, or huge up-front and maintenance costs.

I was honestly wondering, at first, if it would be more fuel and time effective to drill blast holes for ANFO, and clean up the canal faces afterwards. (At least it would be fun!) But, there might be an easier way: keep the bucket wheel's conveyor, for continuous operation, and switch the wheel out for a row of 'jackhammer' shovel teeth, which punch down into the leading face of the canal, and fold the soil onto the conveyor. The shovel face's dig cycle is shown in the sketch. (soon!) Depending upon the way it was attached to the LifeTrac, the jackhammer force on the soil surface could be driven by compressing and releasing the attachment angle; the rear wheel of the LifeTrac hoists up, transferring weight to the support wheels behind the trencher attachment, and when the hydraulics are released, the frame presses the shovel faces into the soil. (more sketches soon)

This is a new kind of earth-mover, so it violates a few OSE specifications - namely, legacy design. But, if the legacy designs are insufficient for our uses, why not make new ones? I'm not about to patent this; I'd love for Sudanese farmers to have it, to dig canals along the Sudd. Heck, if it's fuel-efficient enough, the Indian Subcontinent would go nuts for it. I'll need to get more specifics, to lay out strains and flow rates. Updates shall continue!

Chinampas & Terra Preta

We don't all live in the tropics. But a lot of us do, and in hot climates, the most efficient farming method is widely spaced canals and long, large raised beds with a complimentary mix of crops. The Aztec and later inhabitants of the Valley of Mexico used these swampy gardens to grow maize, squash, beans, and chili, at an estimated input cost of 1 calorie per 120 calories of foodstuffs produced. These chinampas (and Beni camellones, as well as Javanese, Egyptian, Bengali, and Chinese terrace and canal systems) are ideal for combining utilities and recycling wastes through multiple high-value cultures: trees are grown along the waterline, to support the soil bed, aid in filtration and water dispersion through the soil, and provide timber and craft materials; canals are efficient transport routes, reservoirs, and climate control; they grow wet grasses for feed and fertilizer, and can support very productive aquaculture; dense, mixed vegetable plots meet diverse nutritional needs, harvesting 3-4 times a year without fallows, and marginal vegetation supports livestock productivity.

In more arid climates, canals require prohibitive labor costs to set up, and water use is limited. The trencher (hopefully) makes it easier to afford canal-digging, but what about evaporation? I propose covering the canals with clear plastic sheets, propped up on A-frames running the length of the canal zones. With interior 'sluices' and 'reservoirs' along the hem-line of the sheets, condensation is gathered for personal use as purified water. During the day, sunlight heats the water and fills the A-frames with steam. The coolest air is pushed out, under the sides of the canal sheet, along the raised beds. Remaining humidity, cooling in the evening, condenses in the distillation reservoirs. Throughout the day, the condensing humidity that is pushed out from under the sheet completes its condensation in the air just above the raised beds: a thin layer of fog would be visible for most of the morning, providing 'drip' irrigation and protecting crops from wilting heat.

The last piece of the puzzle is soil management: water flow through the soil beds leeches soluble organic nutrients, and chinampa maintenance mostly involves dredging the canal bed for silts and grasses, to re-mineralize the soil. The Beni people of Bolivia and western Brazil solved this problem thousands of years ago. (That qualifies as a legacy technology, right?) Here is how they did it: composted refuse, detritus, and manure ('humanure', too) were allowed to 'stew' in a pit. Fragmented bio-char was added, (I recommend a syngas gasifier to get your char) to bind with bio-active nutrients in the slurry. They'd give it a few days to soak, so the char wouldn't be a nutrient sponge when they added it to the ground. Then, pot sherds were mixed in, until it had a good consistency. The nutrients stuck to the char, and the char painted the ceramic fragments: because pot sherds don't wash away, neither does your plant food. Folks in Brazil call this anthropogenic soil 'Terra Preta do Indio' - 'Indian Black Earth'.

Bio-char is a very porous material - that's what lets it absorb and bind to so many things. And ceramic fragments aren't slouches when it comes to surface area, either. Combined, they provide a huge, pocked surface for microbes and mycelium, they prevent soil compaction and run-off, and are great anchors for root structures. Australian field experiments have shown that, with 10 tonnes of char per hectare (that's 1kg bio-char per 1sq. meter, or almost 5sq.ft. per pound of char), field biomass triples, and NOx off-gassing is cut to 1/5th of pre-char levels. Once terra preta is mixed into surface soils, the microbial cultures will continue to spread downward, extending the zone of fertile soil at a rate of ~1cm/yr. In the many native deposits across the Amazon, locals will mine the soil at regular intervals, scooping up surface cultures for home gardens, and returning years later to find that more of it has grown into the ground. Even with heavy Amazonian rains and floods, these patches have remained fertile without maintenance (and still spread!) since they were created, as long as 3,000 years ago.

So, dig canals with the trencher, cover them with distillation tents, plant complimentary crops, and recycle 'wastes' into terra preta. I'll keep updating with data on input/output rates and estimates of productivity and costs. More diagrams, too.

Insect Farm Module

Especially during the initial phase of GVCS development, local resources are relatively scarce and underdeveloped. The biggest hurdle to new endeavors isn't the level of return on investment - it's the return's velocity. If a farmer has to wait a year, or even a season, before they can feed themselves locally, the choice may be beyond their means. Insects farming is a quick, low-budget way to convert underutilized and abundant resources into fast food, feed, and fertilizer.

Given a local mix of scrap timber, fibrous vegetation, and rotting organic matter, then termite, worm, and black soldier fly 'bug bins' are proven ways to quickly turn inedibles into high protein, fatty, and mineral-rich foods. A goat will do it, too; but only for fresher roughage. Ruminant digestion is very efficient for producing milk, which can be processed and preserved as goods with higher value than bugs, but it's a temperamental gut. So, give the fresh stuff to a goat, and all the junk to the bugs.

There are plenty of OS designs for worm bins, and more soldier fly bin designs are popping up all the time. I'd love to see some good termite set-ups. If we could turn these into modules, for linear attachment and easy swapping/repair, I think we've got a good temperate-climate bug kit. Jungles are different.

There are a lot of bugs in the tropics. This means, anything you look at has a bug that will eat it. Huge potential for composting schemes, right? But they're mostly species-specific consumers. And a lot of those plants are toxic to everyone else. So, instead of trying to contain all those bugs, there's more value in creating a good climate for them around you, and investing in bug-eaters. What that looks like varies, from tropic to tropic. Folks'd have to figure it out. I'm for bats and ground fowl, mostly. :)

Railroad

Mini-Steamer

Large steam engines require strong materials and a good bit of work. Sterling engines operate on smaller temperature gradients, at higher efficiencies (due to heat regeneration which preserves temperature gradients within the pump), but can't manage higher power applications. (Sterling engines can only handle a limited flow rate, because of low rates of heat transfer through the walls.) The goal is a small, mid-power steam engine, with a minimalist design that operates at low pressure, and 'preserves' temperature gradients, for Sterling-like efficiency. Primary use is for pairing with the Fresnel Solar modules. Ideally, the engine would induce current directly, selling back to the grid, or storing power in a battery/capacitor over the course of the day.

My guess is, we could make a doughnut shaped 'piston chamber' with rotating magnetic paddles, wrapped inside a solenoid. (See rough sketch. ...soon) The steam/hot gas enters the radial cavity between two paddles, causing expansion as well as rotation in one direction (the design sketch shows how paddles are linked to each other by their orbiting rings, so that expansion force drives rotation). As the paddle orbits the ring, paddles on the other side press exhaust gas through a second valve. Because the steam enters one side of the ring, and exits after making an almost complete loop, heat transfer to piston walls follows a gradient around the ring. (Traditional steam engine piston chambers alternate between hot and cold, so each new burst of steam must warm its container, as well as expand.) As the steam speeds the orbits of the paddles, their moving magnetic fields induce current in the solenoid. Paddles could move with minimal impedance, for low-pressure steam, or the solenoid resistance could be stepped up, to extract more energy from hotter steam. Stacking modules, and routing exhaust from one into the module above it, would step-down steam temperatures and pressures; the ability to operate with lower pressures would be key for raising total efficiency. Combined Heat & Power (CHP) set-ups could tailor their capital use on the fly, depending upon how much heat was being wasted, simply by adding or removing mini-steamers from their step-down train.

With a ring of orbiting paddles, in-flows are separated from exhaust by multiple seals, reducing the risk of leaks & back-flow, and eliminating the need for troublesome bump valves. Consider, as well, that steam is transferred through a loop, with only the solenoid to impede it: excessive pressure is vented in a single orbit, by a natural increase in paddle speed. No risk of explosive pressures from compression strokes! Also, notice that the lever arm of a traditional steam engine's crank shaft is best at the beginning of the piston stroke, and transfers much less force per arc length as its rotation peaks. (Especially because the force of the piston is greatest at the start, and tapers as expansion completes.) This jerk requires an over-engineered crank shaft! (No, not 'some butt-head in the corner talking about standards' jerk; jerk is change in acceleration over time.) In fact, the solenoid mini-steamer wouldn't even have a crank shaft. DC, baby. :)

I've been contemplating solenoid production: Japanese yosegi (wood mosaics) are my inspiration. (More diagrams coming soon!) On the outside of a roller drum, bend sheets of copper into a spiral, pouring insulating epoxy (or similar material) between the layers just before the roller squeezes them together. Once the ring of conductive/insulating layers has solidified, plane layers off of the flat faces of the ring, to create sheets with pinstripes of copper and insulation. Curling these onto themselves, and bonding the copper, forms a single solenoid coil. Layer these coils, with more epoxy between, to create a nested 'Russian Doll' of many simple solenoids. And, with the equipment for such a technique, how cheap would it be to switch production to capacitors?

At-Work - I was sketching out the flow of pressures in the chamber, and getting rotation to start and stick is a bit trickier than I expected! :) Interesting options, tangents, concepts bubbling up. I'll start the mini-steamer page, to go into discussion of feasibility and limits to maximum power. Each variation I'm looking at has its own kinks, but there might be a good mix between them, or a new direction. Otherwise, I'm happy to toss it in the 'maybe later' or 'not at all' piles.

Component Currency

Organization & Impact Considerations

Training & Spawning

Allocation

Federalism, Leases, Task Mobs

Ecology Behavior

Energy & Substitutes

External Considerations

Marketability & Pull Factors

On Good Will

Urbanization

Hot Spots

Risk & Failure

Theory & Hypothesis

Good Government

Binary Search

The Soft Wall

Emergence & Occam's Razor

Useful Entropy

I should put some information here, before folks get suspicious. Thermodynamics talks about Work - the movement of energy needed to change something. Work isn't energy. It's the movement of hot to cold, the release of tension or pressure, positioned in such a way that it separates hot and cold, or applies tension or pressure, somewhere else. You take the gradient between one pair of objects, (hot/cold, in a steam engine) and move that gradient to another pair (relative motion, for the same case). When we do this 'irreversibly', that means we lost a bit of the gradient. The difference in temperature or pressure you start with is greater than the difference you can create (in a steam engine - to - refrigeration set-up, for example). That's entropy. Stuff leaked, got hot, and wore down - and we can't use it any more, unless we exert more energy. So, we call the part of the gradient that we preserve, 'useful work'. But, is that the only thing in this we can find useful? Now, maybe you're curious. ;)