CEB Press/Manufacturing Instructions/Hopper sheet metal: Difference between revisions

Jump to navigation

Jump to search

No edit summary |

|||

| Line 44: | Line 44: | ||

[[Image:mountedhingeplates.jpg|500px|The hinge plates mounted to the side pieces.]] | [[Image:mountedhingeplates.jpg|500px|The hinge plates mounted to the side pieces.]] | ||

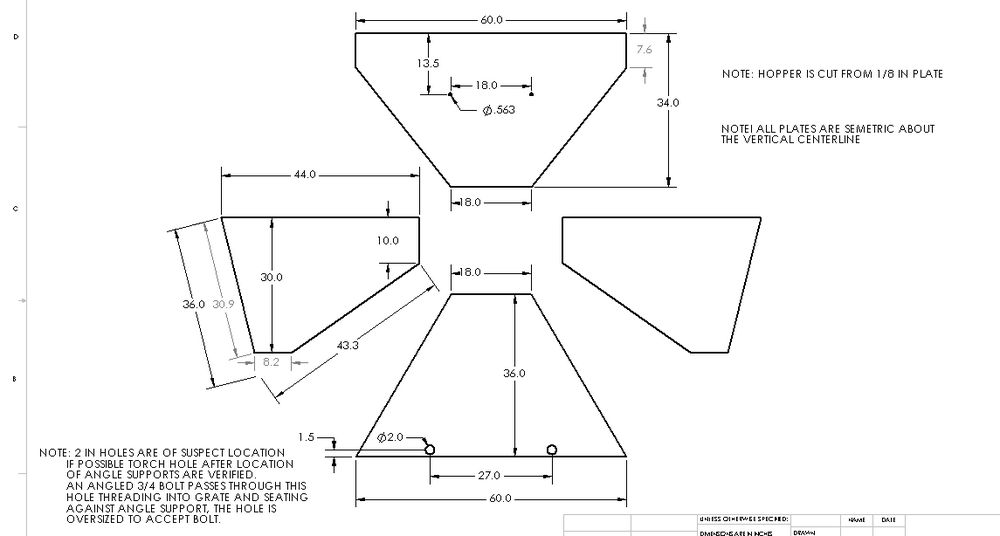

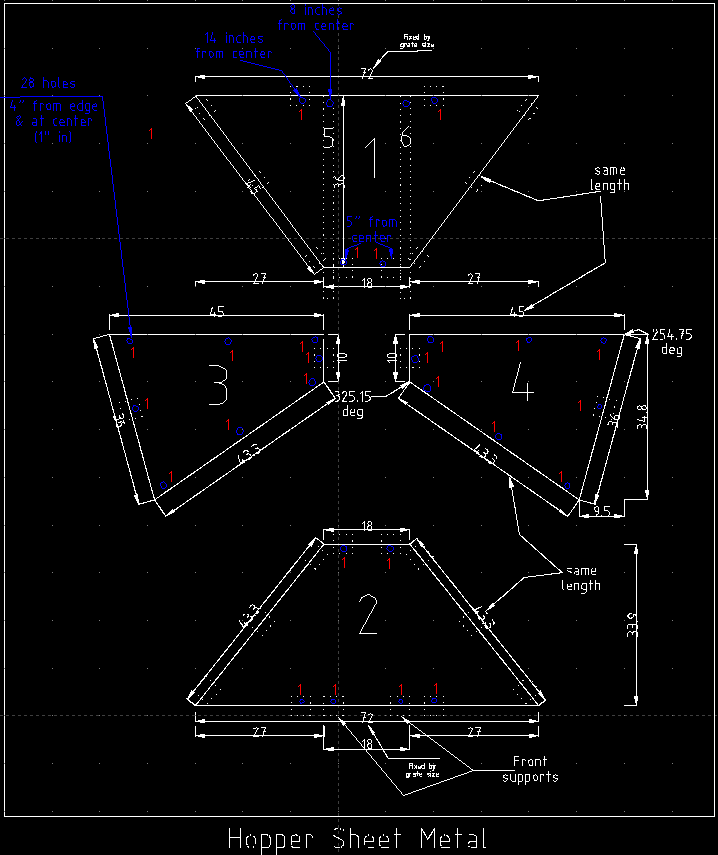

*Torch the hopper shapes. | *Torch the hopper shapes. Grind away any excess slag. Punch all of the holes shown. | ||

[[Image:hopperfab.png|1000px]] | |||

*Place 1/2" bolts thru the side pieces and weld them. | *Place 1/2" bolts thru the side pieces and weld them. | ||

| Line 55: | Line 55: | ||

*Bolt the hinge plate assemblies to the side pieces using a washer, lock washer, and nut on each bolt. | *Bolt the hinge plate assemblies to the side pieces using a washer, lock washer, and nut on each bolt. | ||

Revision as of 04:10, 23 December 2011

Tools

- Torch

- Welder

- Hole punch with 3/4" dies

Materials

- [12] Door Hinges

- [12] 1/2" x 1 1/2" bolts

- [12] 1/2" washers (12)

- [12] 1/2" lockwashers (12)

- [12] 1/2" nuts (12)

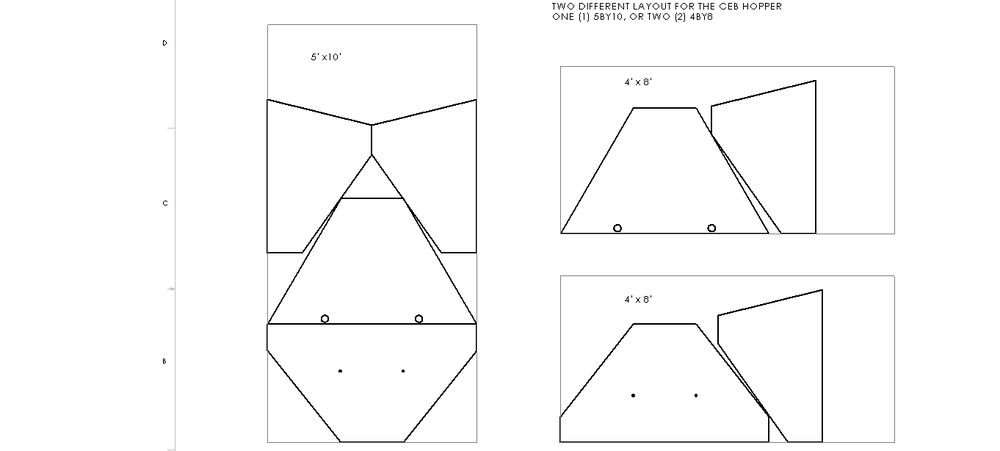

- Steel plate 5' x 10' x 1/8" OR [2] Steel plate 4' x 8' x 1/8"

- Steel bar 3" x 1/8" x 24'

Steps

- Torch components as shown. Note: there are holes in the above diagrams which won't be torched until the hopper installation.

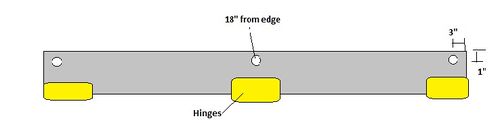

- Punch 3/4" holes in 4 of the hinge plates as shown.

- Weld a holey hinge plate, a non-holey hinge plate and 3 hinges together as shown. Note to make sure the side of the hinge that sticks out most is on the top; this way it won't interfere with the hopper metal below when installing the hopper.

- Torch the hopper shapes. Grind away any excess slag. Punch all of the holes shown.

- Place 1/2" bolts thru the side pieces and weld them.

- Make sure you are making them mirror images of eachother.

- Bolt the hinge plate assemblies to the side pieces using a washer, lock washer, and nut on each bolt.