CNCCMV2: Difference between revisions

| Line 238: | Line 238: | ||

[http://opensourceecology.org/wiki/GRBL Get GRBL] | [http://opensourceecology.org/wiki/GRBL Get GRBL] | ||

[http://opensourceecology.org/wiki/Gctrl Get Gctrl] | |||

=Getting Processing= | =Getting Processing= | ||

Revision as of 04:20, 30 March 2012

Action Plan

- Conceptual Design

- Specific Design

- Sourcing

- Manufacturing

- Testing

- Documentation During All of the Above

Design Rationale

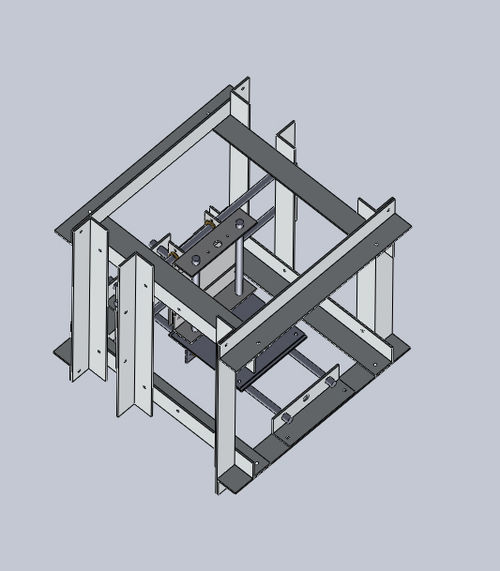

CAD Assembly: CNCube (In Progress)

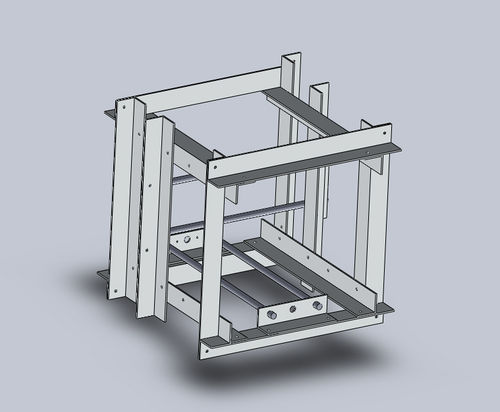

CAD Assembly: XY Frame

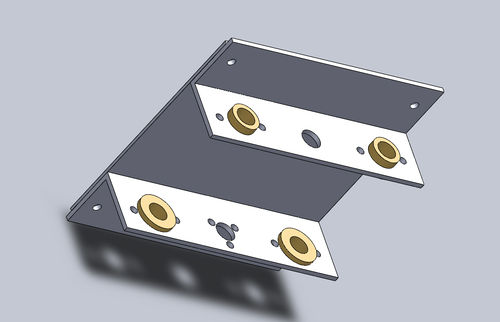

CAD Assembly: Platform

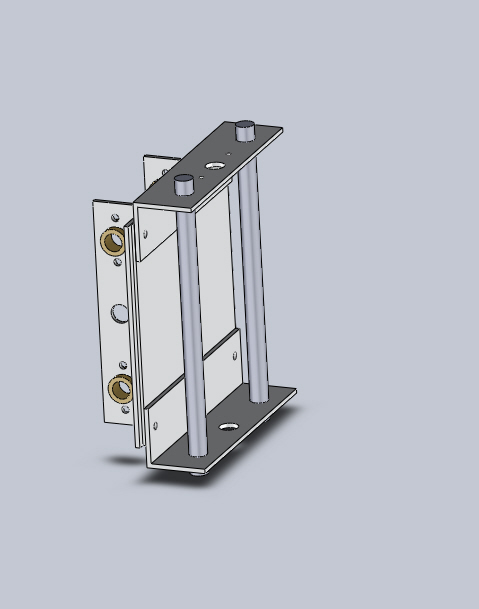

CAD Assembly: Z Frame

Connexions Modules

How to Use the CNC Circuit Mill

How to Design a CNC Circuit Mill

Making the Arduino IDE Work on Linux

Key Performance Specifications

- X Axis Travel Range = 20cm

- Y Axis Travel Range = 20cm

- Z Axis Travel Range = 5cm

- Step Motor Torque at 12VDC = 3.2kg-cm

- Spindle Max Rotation Speed = 22600rpm no-load

- Spindle Motor Torque at 24VDC = 88.5g-cm at max efficiency

- Workpiece Holding Mechanism = Linear Bolt and Tensioning Nut

- For Prototype II, define goals based on study of industry standards. Include desired precision + accuracy + speed.

- Minimum step size for each axis plus variance

- Repeatability of motion (drift) (determined by going to certain locations a large number of times)

- Minimum spacing between traces (determined by minimum allowable size of bit + precision)

- Minimum trace size possible

- Goal: repeatability is as good as step size - ie, all inaccuracy is negligible compared to step size, and zero backlash at all practical milling speeds.

- Define practical milling speed range based on substrate

Key Design Specifications

- Step Motor Axis Drive

- Rotary-to-Linear Motion Converting Stainless Steel Leadscrew and Wear-compensating Leadscrew Nut

- Anti-friction Bronze Sleeve Bearings

- Precision Stainless Steel Axis-Supporting Shafts

- Versatile Holding Platform with Magnets

- Brushed DC Motor Spindle Drive

- Precision Stainless Steel Spindle Shaft

- Computer to Microcontroller to Stepper Driver Electronics Pathway

- Gcode Streamer to Gcode Interpreter Software Pathway

Cost

- Cost values in USD. In practice, some items must be purchased in greater quantity than necessary; the following values are equalized to the correct quantities. List excludes tools and shipping.

- Cube Frame Metal =

- Axes Structure Metal =

- Metal Shafts = 124

- Leadscrews and Leadscrew Nuts = 240

- Bearings = 65

- Fasteners = 70

- Control and Drive Electronics = 130

- Power Supply = 35

- Software = Open Source

- Total =

Sourcing

- Spreadsheet File

LINK HERE

- Prototyping Spreadsheet

- To edit or download the spreadsheet, click on the following link.

https://docs.google.com/spreadsheet/ccc?key=0AlpsBarfpPkzdFk5aDY3dHM0eEhfZHNkWVppdV9EelE

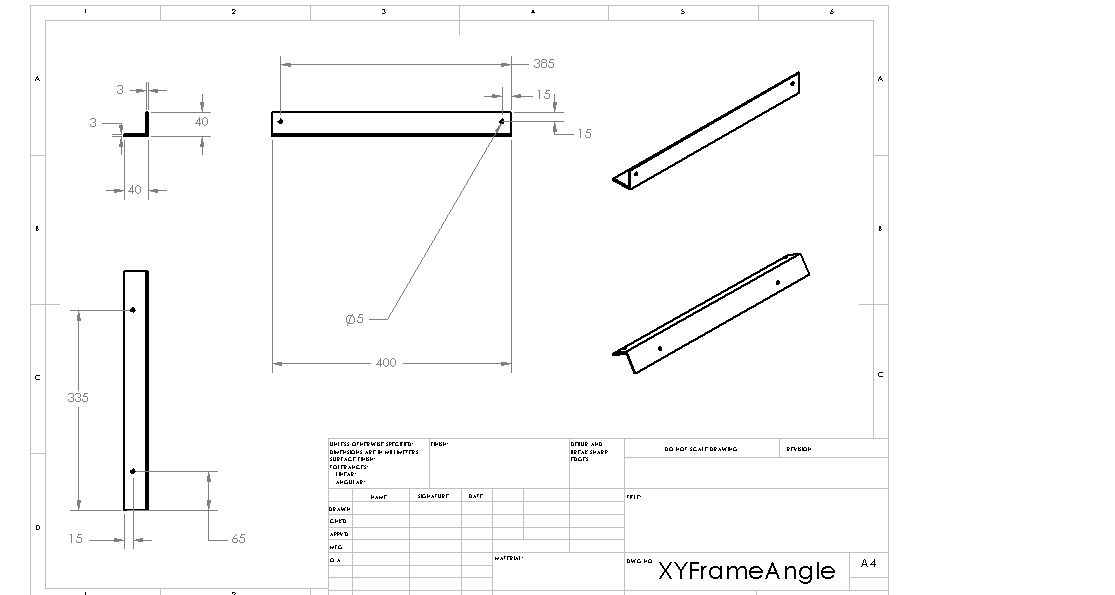

Structure: XY Frame Angle

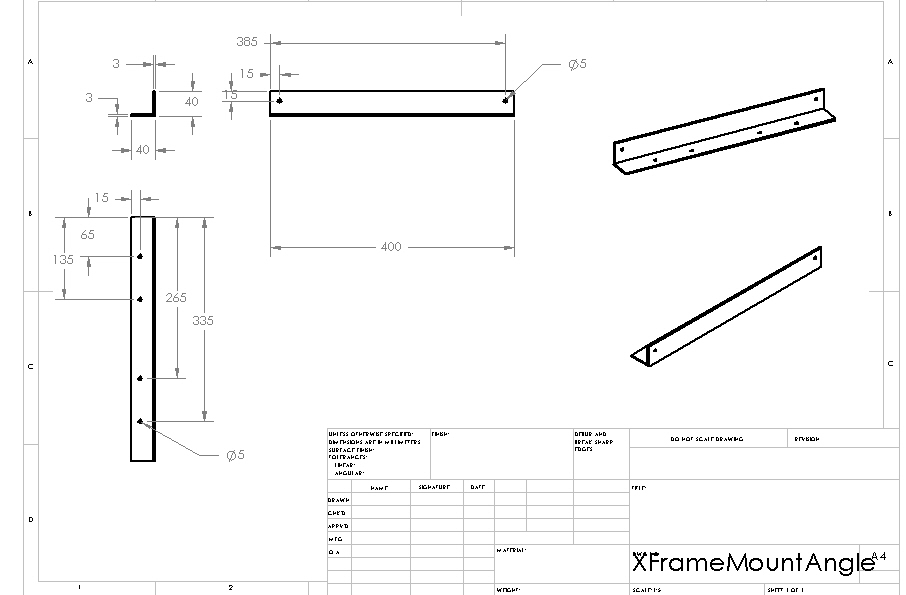

Structure: X Frame Mount Angle

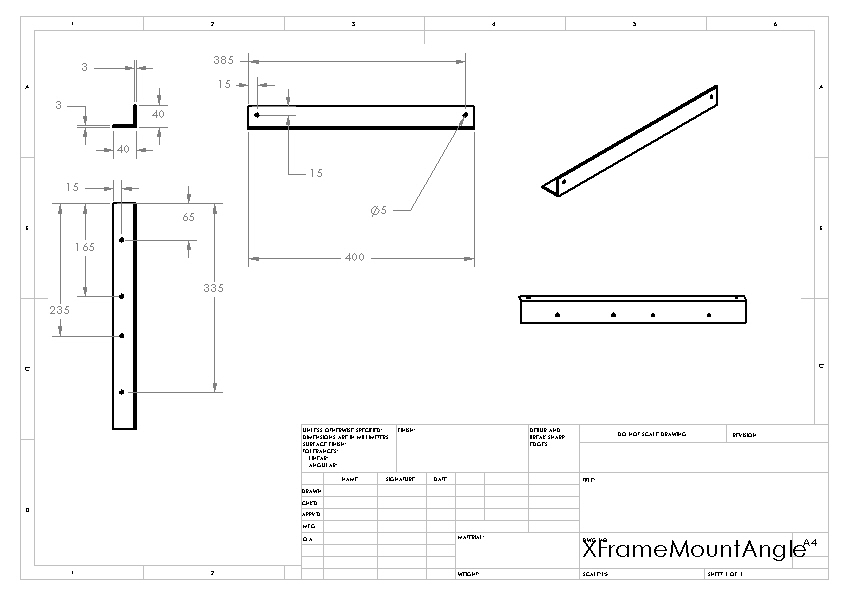

Structure: XY Frame Mount Angle

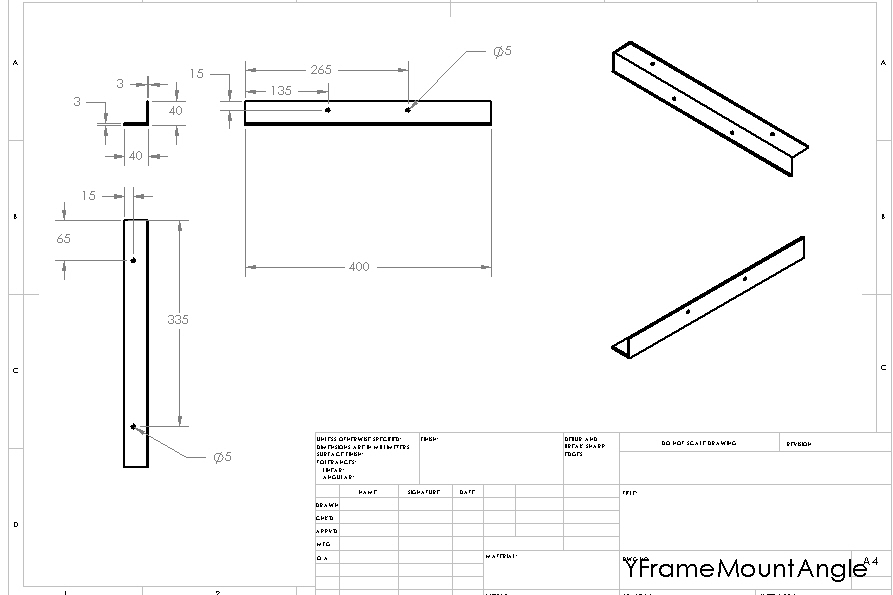

Structure: Y Frame Mount Angle

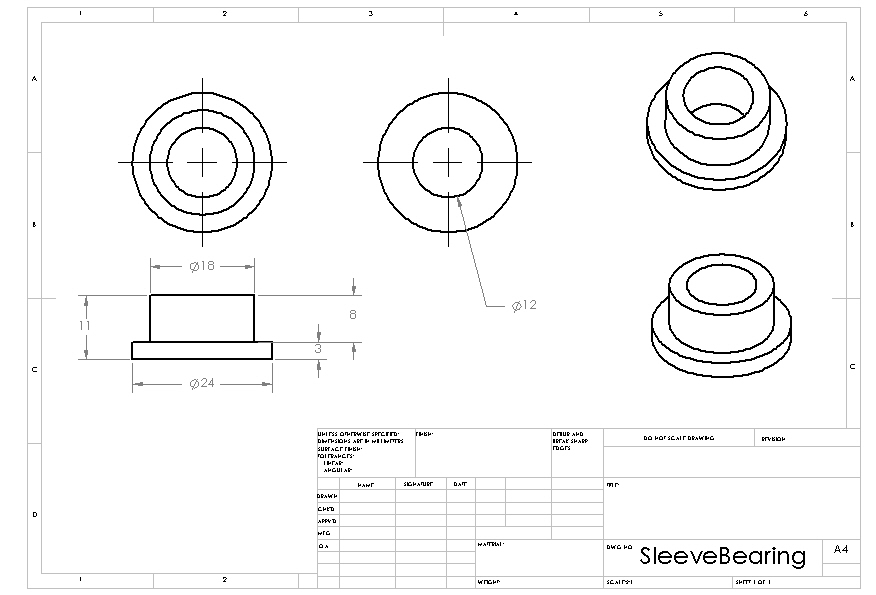

Structure: Sleeve Bearing

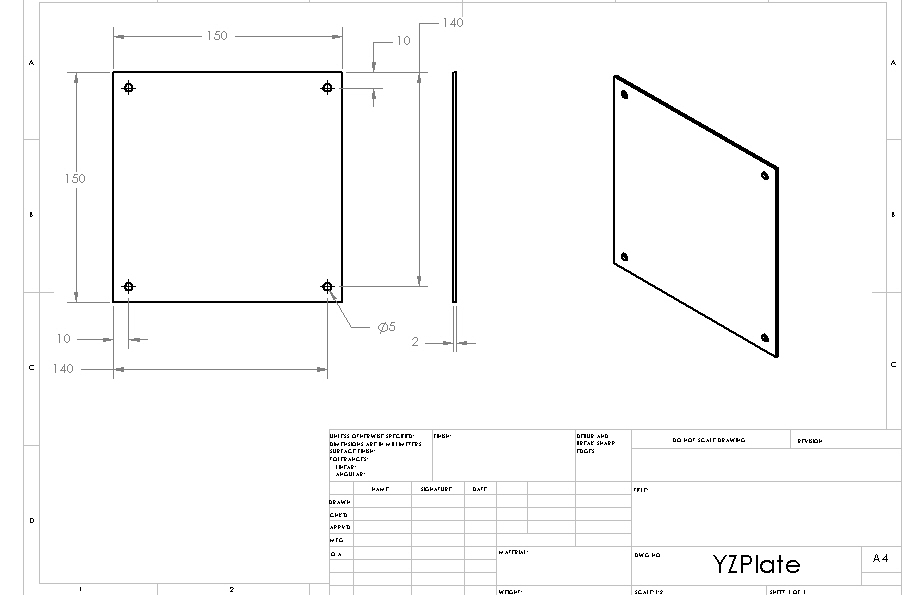

Structure: YZ Plate

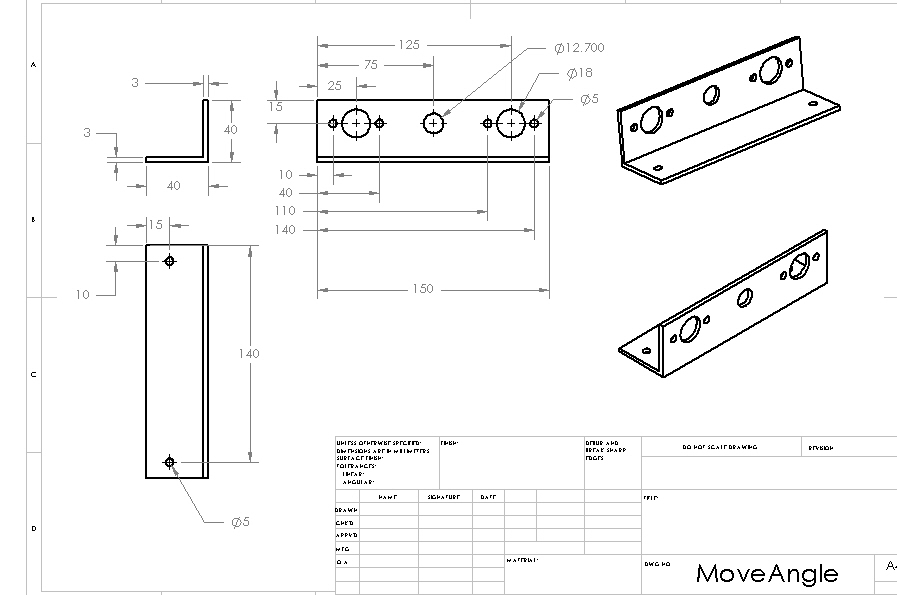

Structure: Move Angle

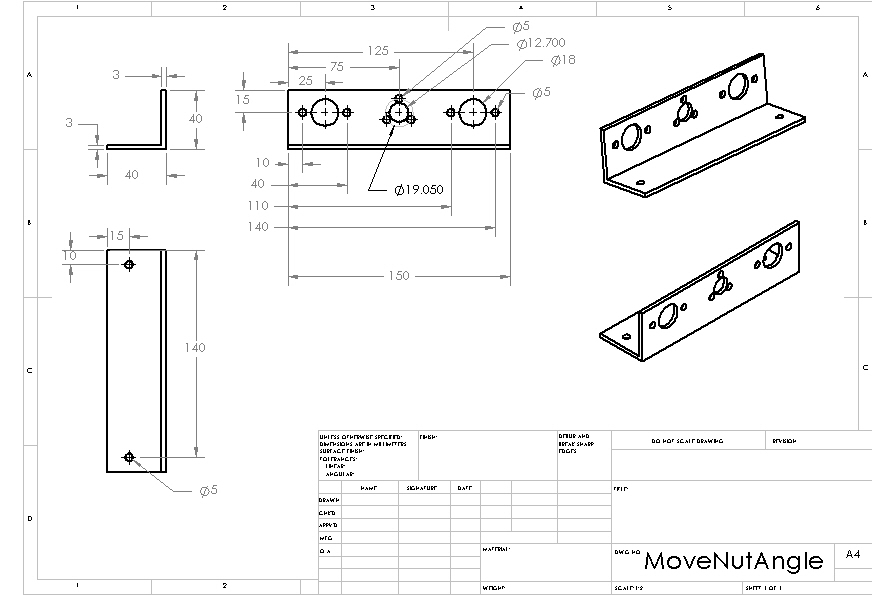

Structure: Move Nut Angle

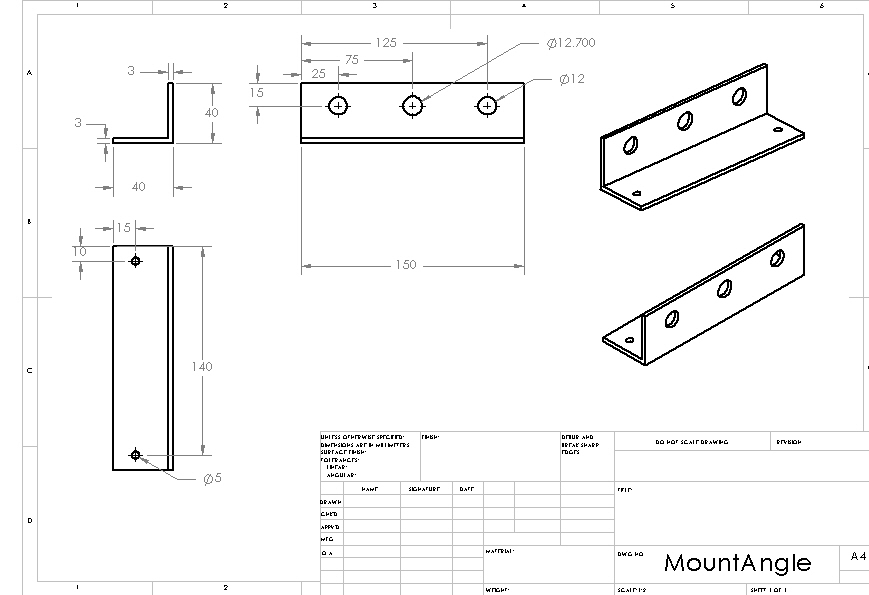

Structure: Mount Angle

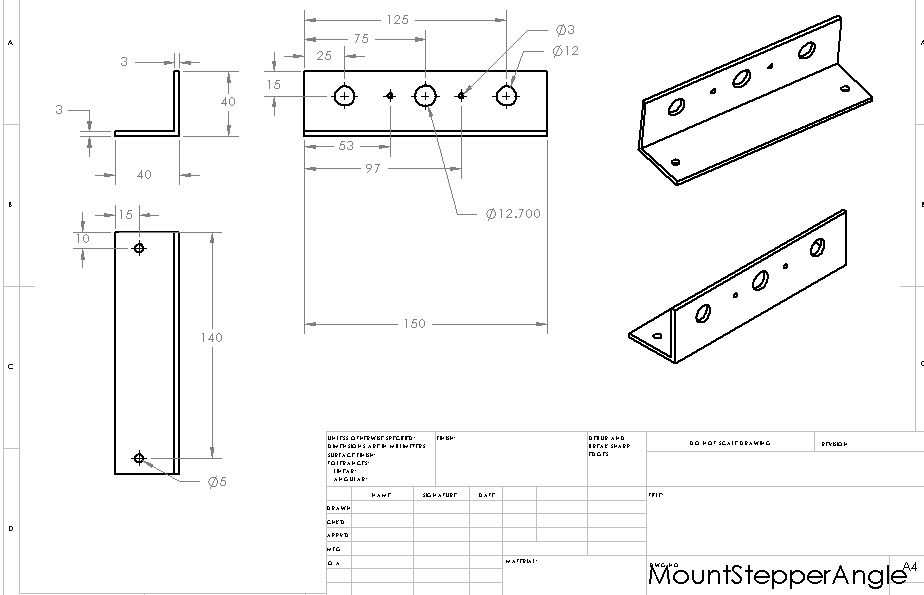

Structure: Mount Stepper Angle

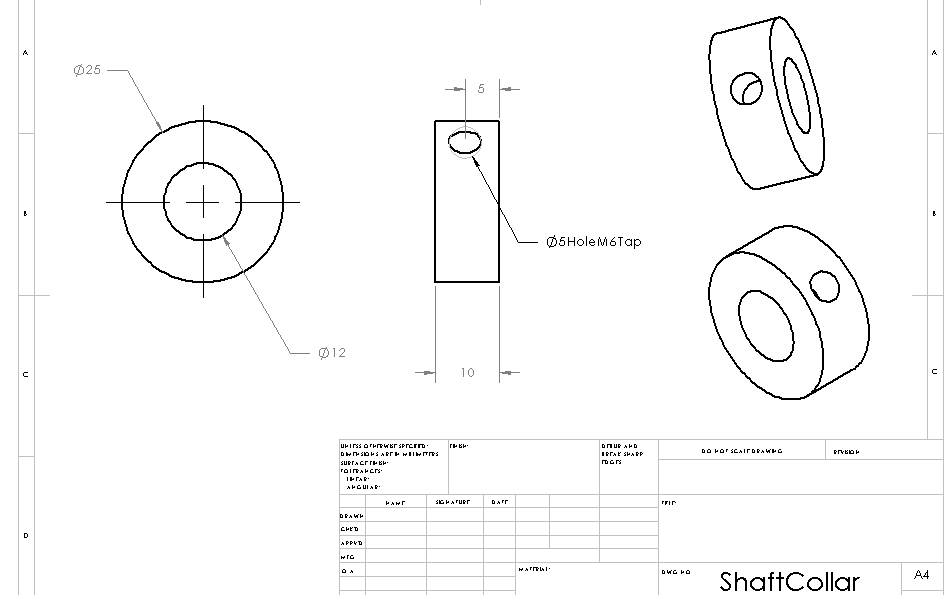

Structure: Shaft Collar

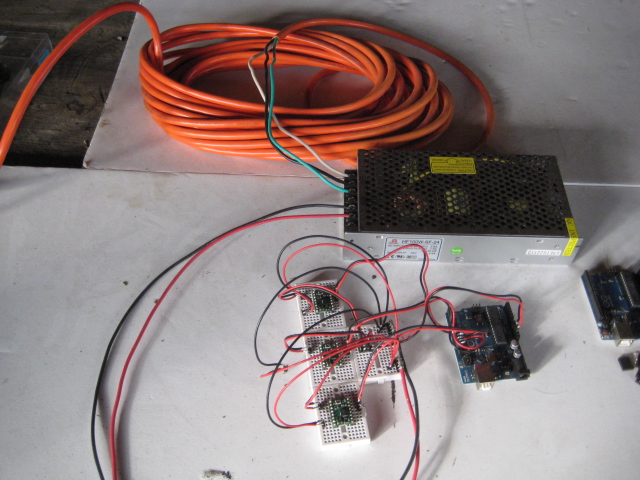

Electronics

Soldering Stepper Driver Pins

- Insert the short end of the male headers into the stepper driver board from the bottom, then pressfit the headers into the small breadboard for holding.

- Apply flux to all header connections

- Apply solder to the tip of the soldering iron

- Solder header connections at opposite corners of the stepper driver board for stability, reapplying solder to and cleaning the soldering iron tip as necessary; repeat for the remaining header connections.

Soldering Connectors

Wiring

Software

Ubuntu 10.04 LTS 32-Bit

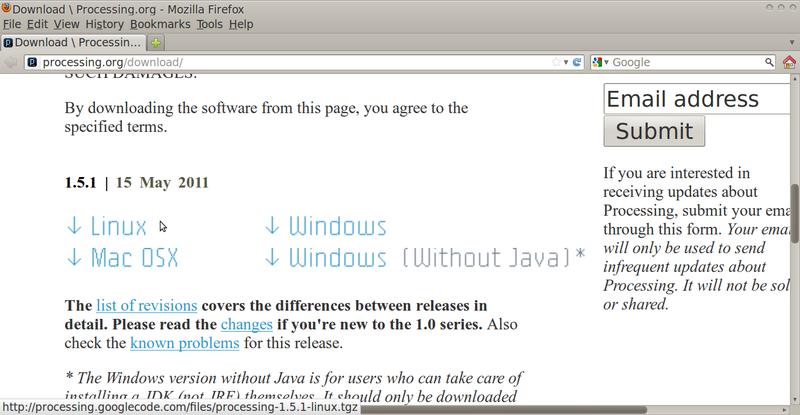

Getting Processing

- Go to this webpage:

http://processing.org/download/

- Download the latest version of Processing to a directory of your choosing

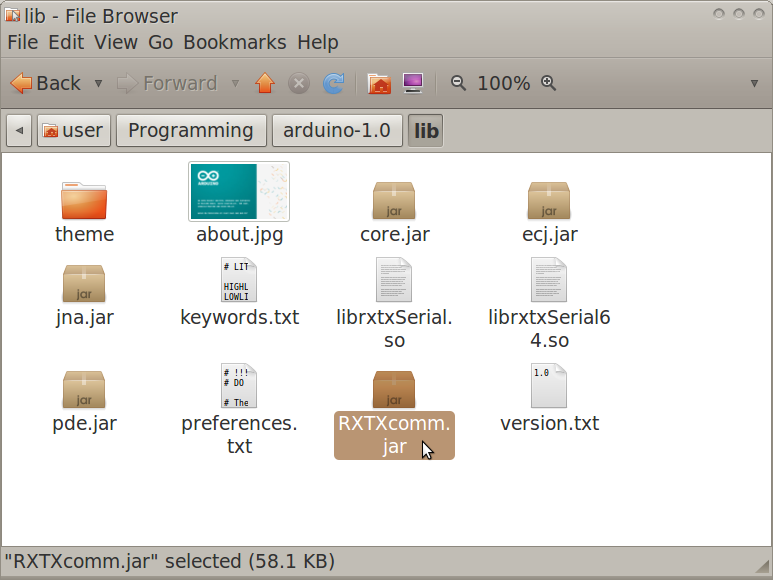

Moving RXTX files

- Navigate to the Arduino IDE folder>lib.

- Copy RXTXcomm.jar

- Navigate to the Processing folder>modes>java>libraries>serial>library

- Paste RXTXcomm.jar, replacing the existing version

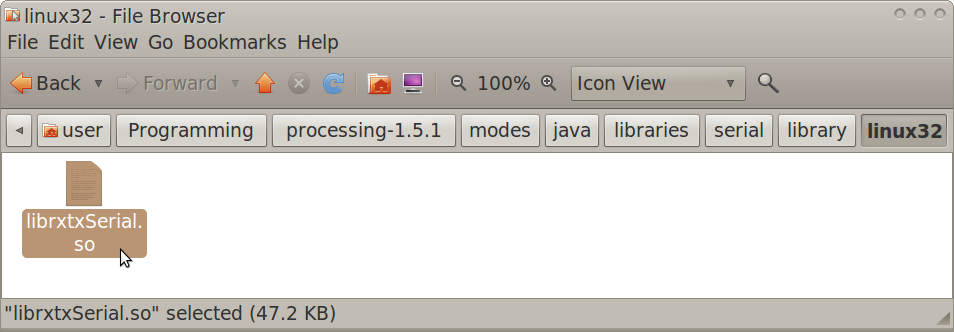

- Navigate to the Arduino IDE folder>lib

- Copy librxtxSerial.so

- Navigate to the Processing folder>modes>java>libraries>serial>library>Linux32

- Paste librxtxSerial.so, replacing the existing version

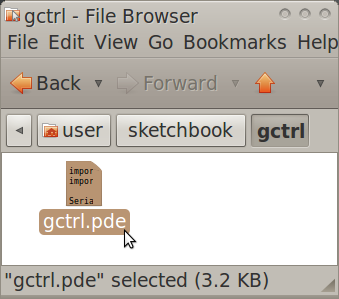

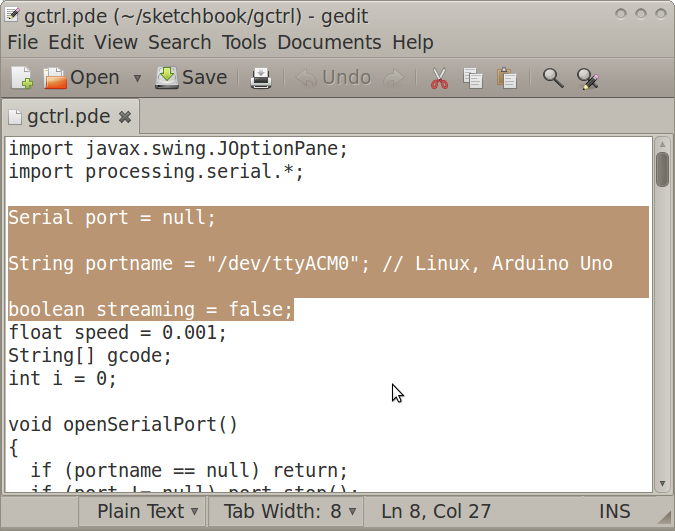

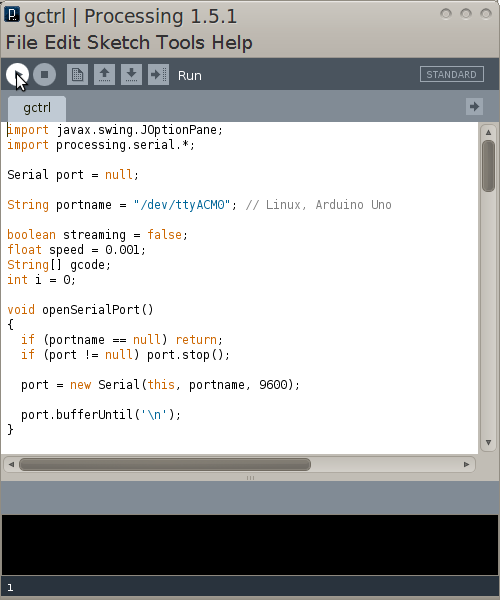

Modifying Gctrl

- Open the Gctrl folder

- Open gctrl.pde in gedit

- Change a part of the code as annotated in the following:

Serial port = null; //change starts

String portname = "/dev/ttyACM0"; // Linux, Arduino Uno

//change ends

boolean streaming = false;

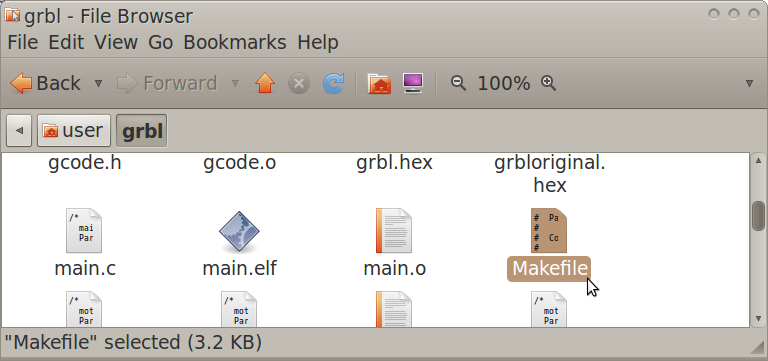

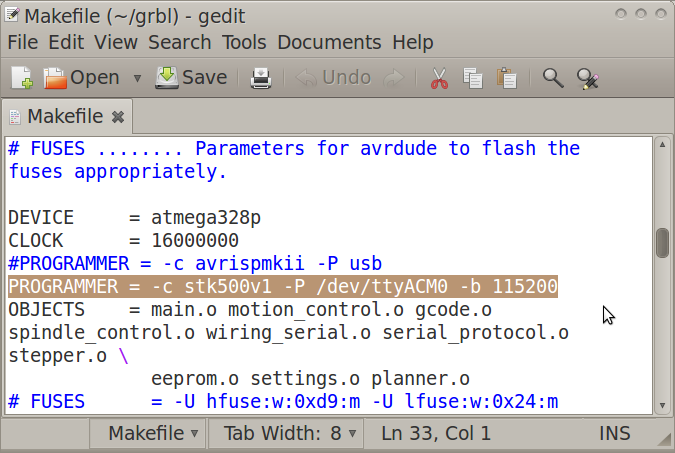

Modifying GRBL Files

- Navigate to the GRBL folder

- Open "Makefile" in gedit

- Edit the PROGRAMMER line as:

PROGRAMMER = -c stk500v1 -P /dev/ttyACM0 -b 115200

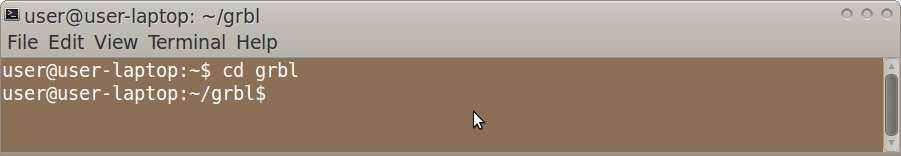

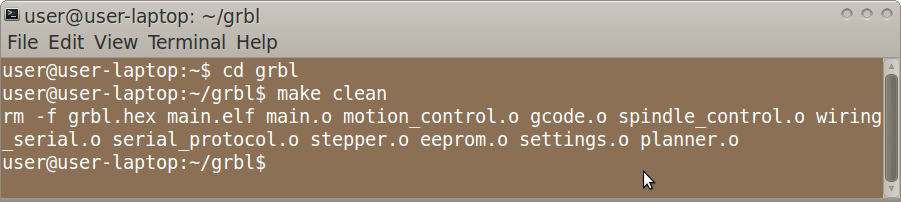

Flashing GRBL

- Open Terminal and navigate to the GRBL folder (ex. by using the "ls" and "cd" commands)

- In Terminal, type:

make clean

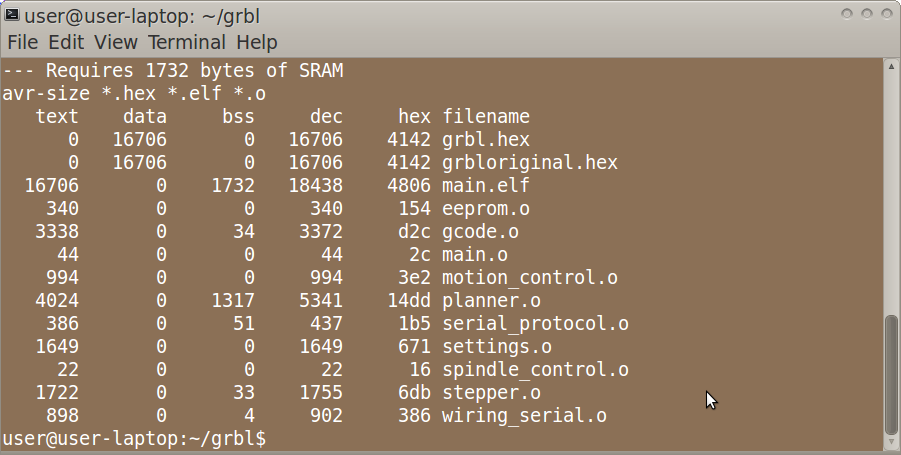

- In Terminal, type:

make

- Connect the Arduino Uno to the computer via USB cable

- In Terminal, type:

make flash

- Disconnect the Arduino Uno

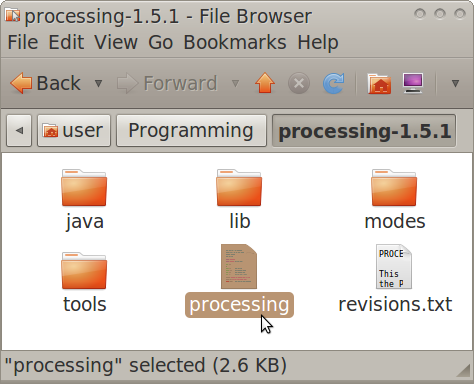

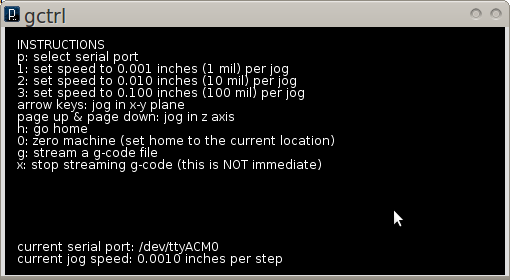

Running Gctrl

- Navigate to the Processing folder

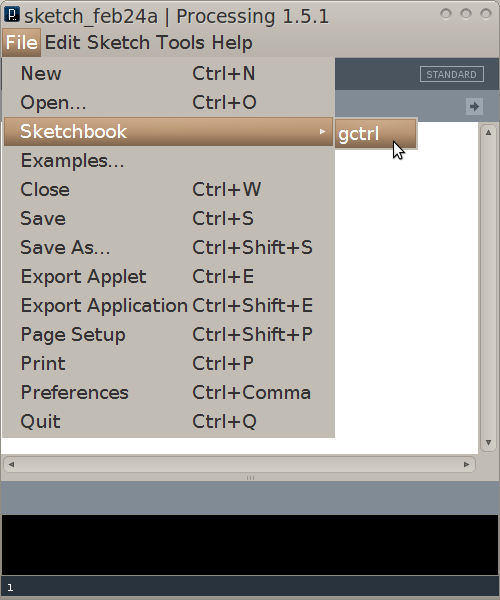

- Open and run Processing, setting the sketchbook folder as the folder in which the gctrl folder exists

- In Processing, open gctrl using File>Sketchbook>

- Connect the Arduino Uno to the computer via USB cable

- In Processing, run gctrl using Sketch>Run

- Now the Gctrl GUI window should pop up

- Note: For certain functions of gctrl, press and hold down the key for the popup windows to populate.

Determining GRBL Configuration Changes Required

- Go to the following webpage:

http://dank.bengler.no/-/page/show/5474_configuringgrbl?ref=mst

Modifying GRBL Settings

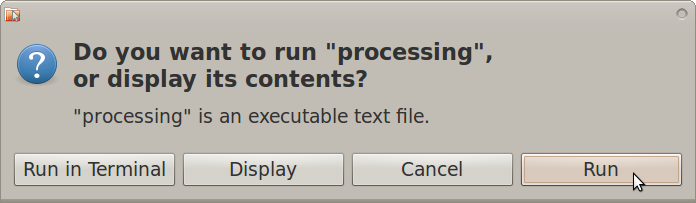

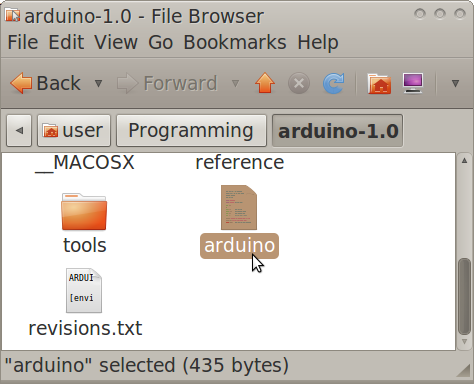

- Navigate to the Arduino IDE folder

- Double-click "Arduino" then click "run" in the popup window

- Note: you may want to create a quick launcher for the Arduino IDE

- Connect the Arduino Uno to the computer via USB cable

- In Arduino IDE, open Tools>Serial Monitor

- Note: the Serial Monitor window should pop up and you should see the following:

Grbl 0.6b

'$' to dump current settings

- In the Serial Monitor, change the left drop-down setting to the following:

Both NL & CR

- In the Serial Monitor, type the following in the command line:

$

- Note: you should now see the following:

$0 = 157.480 (steps/mm x)

$1 = 157.480 (steps/mm y)

$2 = 157.480 (steps/mm z)

$3 = 10 (microseconds step pulse)

$4 = 500.0 (mm/min default feed rate)

$5 = 600.0 (mm/min default seek rate)

$6 = 0.100 (mm/arc segment)

$7 = 0 (step port invert mask. binary = 0)

$8 = 25.0 (acceleration in mm/sec^2)

$9 = 225.0 (max instant cornering speed change in delta mm/min)

'$x=value' to set parameter or just '$' to dump current settings

- In the Serial Monitor, type commands as necessary in the following format, where "X" and "Y" are numbers:

$X = Y

Design Modifications

Modularity

- Different step motors and drive mechanisms can be mounted onto the axis support angles via mounting holes

- Different frames can be used, provided they have precise mounting holes for the axis support angles

- Different holding platforms can be used, provided they have mounting holes for the X axis moving angles

- Different spindle setups can be used, provided they have mounting holes for the Z axis moving angles

- Different stepper driver boards and power supplies can be used, provided they have compatible performance specifications within the electronics system

Scaling

- Scaling mainly consists of changing the size of the frame (to affect travel ranges) and the type of step motors (to affect travel rates)

- Other discrete components such as fasteners, leadscrews, and shafts need only be scaled if necessary for functionality or certain desired performance specifications

- The travel range calculation for the X axis:

(X Travel Range) = (Distance Between 2 Parallel Frame Angles Along Horizontal Plane) - (Length of Platform Along Axis)

- The travel range calculation for the Y axis:

(Y Travel Range) = (Distance Between 2 Parallel Frame Angles Along Vertical Plane) - (Length of Z Support Angles Along Axis)

Usage

- Circuit Schematic to Gcode File Toolchain

- See following link for list of electronic design suites:

http://en.wikipedia.org/wiki/Comparison_of_EDA_software

- PCB-Gcode Optimizer

http://cnc.goodbits.net/wiki/index.php5/Pcb-gcode_optimizer

http://www.millpcbs.com/index.php?option=com_content&view=article&id=10&Itemid=44

Maintenance

Distributive Enterprise

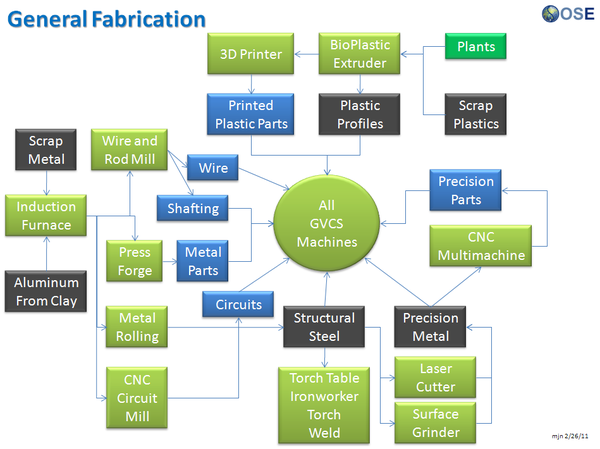

GVCS Product Ecology

Uses

- Induction Furnace - Steel

- Aluminum Extractor - Aluminum

- Metal Roller - Fasteners, Metal Angles, and Flats

- Rod and Wire Mill - Wires, Shafts

- CNC Multimachine - Bearings, Leadscrews, Leadscrew Nuts

- Motors - XYZ Movement

- CNC Circuit Mill - Control Circuit Boards

- Universal Power Supply - Power

Creates

- Milled Circuit Boards

See Product Ecologies for more information.