Compressed Air Water Pump: Difference between revisions

Jump to navigation

Jump to search

| Line 3: | Line 3: | ||

http://www.hydromissions.com/products.htm | http://www.hydromissions.com/products.htm | ||

http://www.hydromissions.com/slapshotconstruction.pdf | http://www.hydromissions.com/slapshotconstruction.pdf | ||

| Line 9: | Line 10: | ||

[[Image:compressedairwaterpump.jpg]] | [[Image:compressedairwaterpump.jpg]] | ||

==Timer== | |||

*http://www.grainger.com/Grainger/items/2A560 | |||

=Design 1= | =Design 1= | ||

Revision as of 17:25, 12 June 2009

Research

http://www.hydromissions.com/products.htm

http://www.hydromissions.com/slapshotconstruction.pdf

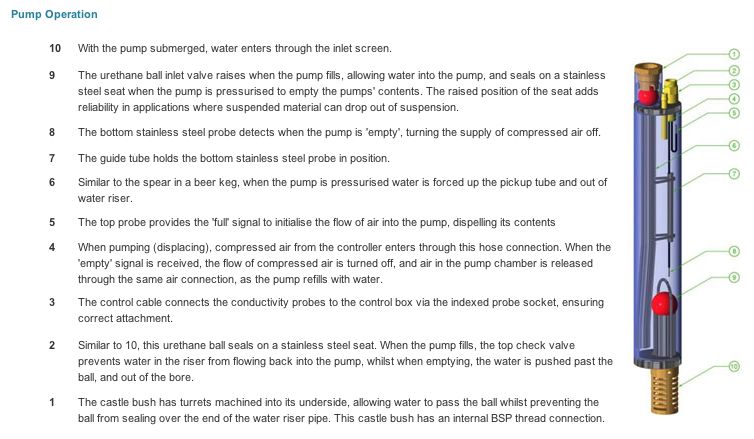

From http://www.airwellpumps.com/HowDoesItWork.aspx :

Timer

Design 1

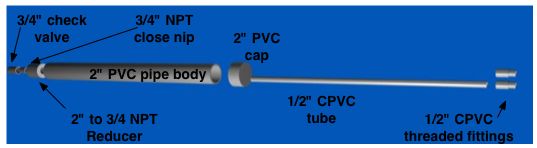

BOM

- 2' x 2" PVC pipe

- 2" flat PVC cap

- 2" Spigot x 3/4" Fips [1]

- 3/4" male thread coupling

- 3/4" brass check valve

- 2 x 3/4" male threaded PVC plugs

- 2' x 3/4" PVC pipe

- 2 x 3/4" hoses long enough to go down the well

Construction

- Ream out one 3/4" male threaded PVC plug with a 3/4" hole for the 2' x 3/4" pipe and attach them.

- Drill two 5/8" holes in the flat PVC cap and tap them to 3/4" for the air in and water out 3/4" male threaded PVC plugs. Use plumbers tape and attach the plugs. Glue the PVC cap to the 2' x 2" pipe.

- Remove the spring of the metal check valve like in the hydromissions slapshot instructions.

- Glue the 2" to 3/4" plug to the other end of the 2' x 2" pipe, attach the 3/4" male threaded coupler and the 3/4" check valve.

- Attach the hoses to the plugs with plumbers tape and clamps and test the pump.

Assembly Diagram

Video