Cory Shenk's Log: Difference between revisions

Cory Shenk (talk | contribs) No edit summary |

Cory Shenk (talk | contribs) No edit summary |

||

| Line 1: | Line 1: | ||

==June 5, 2013== | ==June 5, 2013== | ||

==Truck: Rear== | |||

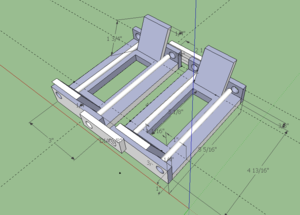

[[File:Truck rear1.PNG|thumb|300px|June 5, 2013 Truck: Rear with dimensions]] | |||

[[File:Truck rear2.PNG|thumb|300px|June 5, 2013 Truck: Rear Front View]] | |||

[[File:Truck rear axle.PNG|thumb|300px|June 5, 2013 Truck: Rear Axle]] | |||

-Constructed the axle with 4" square tubing. | |||

-Made the truck bed wider, slightly over 4' to allow loading of standard size plywood. | |||

-Added 2" square tubing for rigidity in sides. Hopefully they are available, or another solution will be needed. | |||

-Still have to design wheel hubs. Bent rebar would be fast, but not modular. I am thinking that I will stack two 4" tubes on top of each other which will allow clearance and then lay flat metal across. This area is not load bearing. There could be a solution far lighter and cheaper not using metal. | |||

[[File:Shenk truck back.skp]] | |||

==MicroTrac: Tracks== | |||

[[File:MT tracks proper.PNG|thumb|300px|June 5, 2013 MicroTrac track component]] | [[File:MT tracks proper.PNG|thumb|300px|June 5, 2013 MicroTrac track component]] | ||

Revision as of 23:26, 5 June 2013

June 5, 2013

Truck: Rear

-Constructed the axle with 4" square tubing. -Made the truck bed wider, slightly over 4' to allow loading of standard size plywood. -Added 2" square tubing for rigidity in sides. Hopefully they are available, or another solution will be needed. -Still have to design wheel hubs. Bent rebar would be fast, but not modular. I am thinking that I will stack two 4" tubes on top of each other which will allow clearance and then lay flat metal across. This area is not load bearing. There could be a solution far lighter and cheaper not using metal.

MicroTrac: Tracks

The tracks that I had been working on were scaled down from the tracks off of the LifeTrac which was incorrect. Here I have drawn the component with the correct sizes for the track that will fit to the MicroTrac. I was unable to figure out how to include the dimensions for the holes; they are all 3/8" in diameter. The rebar pieces are all #2 (1/4").

I tested the rotation and it appears that even if the track components were both to rotate at a 45 degree angle they will still not interfere with each other. In the case of the tracks, they should never rotate that far.

The attachment/adjustment component should still work with this design. It will have to be redrawn to fit this new model.

While thinking about the adjusting and attaching I have wondered if it would be a good idea to have two or four points for adjustment similar to snow chains on large trucks.

June 4, 2013

Completed tracks for MicroTrac with proposed attachment/adjustment component.

Changes

Modified track with completed track component and proposed attachment/adjustment component. File:Micro fulltrack6 4.skp