Sawmill Design 2: Difference between revisions

Jump to navigation

Jump to search

No edit summary |

|||

| Line 11: | Line 11: | ||

=Calculations= | =Calculations= | ||

[[https://www.surpluscenter.com/techhelp.asp?UID=2009092710404007&catname=hydraulic Hydraulic motor power]] = torque (in-lb)*RPM/63k | [[https://www.surpluscenter.com/techhelp.asp?UID=2009092710404007&catname=hydraulic Hydraulic motor power]] = torque (in-lb)*RPM/63k | ||

*Take | *Take [https://www.surpluscenter.com/item.asp?UID=2009092710404007&item=9-1184&catname=hydraulic 5000 RPM, 166 in-lb motor] for 13 hp | ||

*take [ larger motor] | |||

=Bill of Materials= | =Bill of Materials= | ||

*Four .6" hub v-groove bearings - [http://www.vxb.com/page/bearings/PROD/V-Groove-Bearings/Kit8408 $25 each] | *Four .6" hub v-groove bearings - [http://www.vxb.com/page/bearings/PROD/V-Groove-Bearings/Kit8408 $25 each] | ||

Revision as of 15:52, 27 September 2009

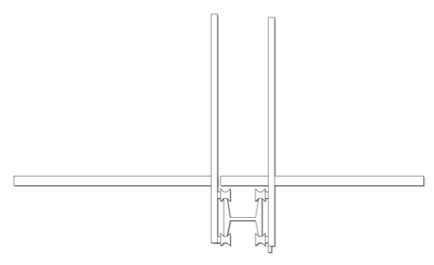

What if we use steel sections to eliminane need for building a track?

10x4" I-beams in the 20 lb/ft range are available - see PDF page 132 in Structural Steel Sections

Use 30" hydraulic cylinders for y and z motion in a cantilevered configuration along the steel section x axis. Absolute simplest design is obtained, if 40 and 20 hp hydraulic motors are used for a 20" and 10" sawmill blade.

High performance, 60 hp sawmill at about $1000 in parts. Another breakthrough, as similar power costs at least $25k.

Calculations

[Hydraulic motor power] = torque (in-lb)*RPM/63k

- Take 5000 RPM, 166 in-lb motor for 13 hp

- take [ larger motor]

Bill of Materials

- Four .6" hub v-groove bearings - $25 each