Foundry: Difference between revisions

(divide up into "heating techniques" and "crucible designs") |

(move related things together) |

||

| Line 1: | Line 1: | ||

=Introduction= | == Introduction == | ||

A foundry is useful for converting otherwise unusable scrap metal into useful metal parts by melting the metal and casting it into desired shapes. | A foundry is useful for converting otherwise unusable scrap metal into useful metal parts by melting the metal and casting it into desired shapes. | ||

| Line 27: | Line 27: | ||

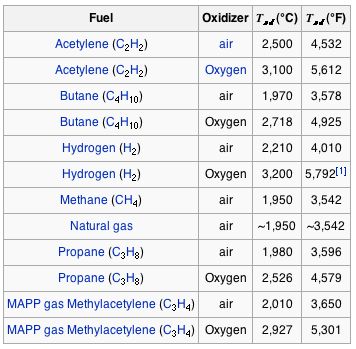

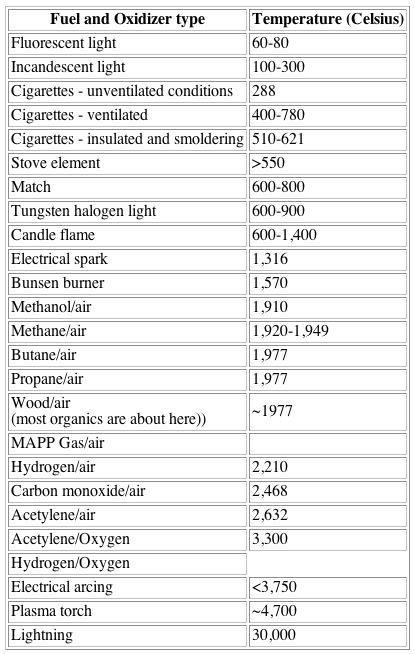

*Flame temperatures from [http://www.derose.net/steve/resources/engtables/flametemp.html]: | *Flame temperatures from [http://www.derose.net/steve/resources/engtables/flametemp.html]: | ||

[[Image:flametemps2.jpg]] | [[Image:flametemps2.jpg]] | ||

====Is there a way to do an oil-fired steel-melting furnace?===== | |||

Does this work? | |||

http://thesteelyard.blogspot.com/2008/06/waste-oil-fired-furnace-for-bronze-iron.html | |||

| Line 38: | Line 44: | ||

=== concentrated solar foundry === | === concentrated solar foundry === | ||

== electric arc furnace == | == electric arc furnace == | ||

| Line 72: | Line 70: | ||

Reversion refers to substituting knowhow, raw materials, and labor for off-shelf products. Using this technique, we can make steel-melting crucibles, to reduce costs. Crucibles for 300 pound shots are several hundred dollars. The materials cost about 10x less. | Reversion refers to substituting knowhow, raw materials, and labor for off-shelf products. Using this technique, we can make steel-melting crucibles, to reduce costs. Crucibles for 300 pound shots are several hundred dollars. The materials cost about 10x less. | ||

==Crucibles== | ==Crucibles== | ||

Getting the scrap metal into a cold crucible is the easy part. | |||

How do you get the molten metal out of the hot crucible? | |||

*200 lb dipout furnace for sale - [http://www.ufes.com/index.php?n=Foundry.200LBDipoutFurnace] | |||

*3000F rocker furnace for sale, 750 lb per hour after first heat - electric with 2 electrodes - [http://www.ufes.com/index.php?n=Foundry.Detroit750LYPRockerFurnace] | |||

Crucibles are made from special clays. | Crucibles are made from special clays. | ||

| Line 108: | Line 115: | ||

*'''Principles of Foundry Technology''', Google Book - [http://books.google.com/books?id=k1slD5MmhUMC&pg=PA215&lpg=PA215&dq=thermal+efficiency+of+a+foundry&source=bl&ots=U1v2nNJcd0&sig=iQrFmmxyPiLNvAMbvhGwFZvpejA&hl=en&sa=X&oi=book_result&resnum=5&ct=result#PPA204,M1] | *'''Principles of Foundry Technology''', Google Book - [http://books.google.com/books?id=k1slD5MmhUMC&pg=PA215&lpg=PA215&dq=thermal+efficiency+of+a+foundry&source=bl&ots=U1v2nNJcd0&sig=iQrFmmxyPiLNvAMbvhGwFZvpejA&hl=en&sa=X&oi=book_result&resnum=5&ct=result#PPA204,M1] | ||

=Induction Furnace= | =Induction Furnace= | ||

Revision as of 17:50, 16 April 2010

Introduction

A foundry is useful for converting otherwise unusable scrap metal into useful metal parts by melting the metal and casting it into desired shapes.

- Steel melts at around 2500F, 1350C, or slightly below pure iron

- Iron melting point - 2800F, 1540C, 1811K

- Cast iron melting point - 1150-1200C, about 300C lower than pure iron

- From [1]:

- Steel is iron and up to 2.0% carbon without any other alloying elements

- Above 2.0% C we are dealing with cast iron. Cast iron tends to be brittle, unless it is ductile cast iron.

- The steel melting point varies between 1540°C and 1400°C, gradually declining with increasing carbon content.

There are a variety of heating techniques used to reach these temperatures, including:

- fuel burning

- electric induction heating

- electric microwave heating

- electric arc heating

- concentrated solar

heating techniques

fuel burning foundry

- Flame temperatures from Wikipedia:

- Flame temperatures from [2]:

Is there a way to do an oil-fired steel-melting furnace?=

Does this work? http://thesteelyard.blogspot.com/2008/06/waste-oil-fired-furnace-for-bronze-iron.html

induction heating foundry

- College foundry, 100 lb steel or iron, 100 kW induction furnace - [3]

microwave heating foundry

concentrated solar foundry

electric arc furnace

- Arc furnace, 175kW, 700 lb/hour -[4]

- Based on this explicit value, basic extrapolation can be done to figure out the amount of fuel required to provide this heat via simple burning. If LifeTrac burns under 1 gallon of fuel per hour, and it has a total energy use (including thermal waste) of about 100 kW, this indicates that about 2 gallons per hours should suffice to produce 700 of steel per hour. Given inefficiencies - say 50% heat transfer - we should produce 350 lb of steel per hour if we burned fuel for direct heat. The basic figure that arises is about 1 pound of fuel to 20 pounds of melted iron.

- Induction Furnace - 40 kW - http://www.ufes.com/index.php?n=Foundry.InductothermInductionFurnaceModel40-96

- ARC, 53kW, 560 lb - [5]

- Induction 4000 lb for 100kW, or 1000 lb for 25 kW? - [6]

Heat Requirement Calculations

- Based on the specific heat of iron and its melting temperature, the energy requirements for meling iron are calculated:

- Converting this to fuel requirements based on the energy content of fuels for a give weight of fuel, we can calculate the amount of fuel required for melting. Heat losses such as total inefficiencies of heat transfer to the metal need to be included:

Plans

Using coke as fuel: "Iron Melting Cupola Furnaces for the Small Foundry" by Steve Chastain[7]

- Plans for a 330 lb/hour iron melting foundry - [8]:

Reversion

Reversion refers to substituting knowhow, raw materials, and labor for off-shelf products. Using this technique, we can make steel-melting crucibles, to reduce costs. Crucibles for 300 pound shots are several hundred dollars. The materials cost about 10x less.

Crucibles

Getting the scrap metal into a cold crucible is the easy part. How do you get the molten metal out of the hot crucible?

- 200 lb dipout furnace for sale - [9]

- 3000F rocker furnace for sale, 750 lb per hour after first heat - electric with 2 electrodes - [10]

Crucibles are made from special clays.

- What is the composition?

- Where do we procure the materials?

- How do we make the crucible?

- What is the total cost?

Collaboration Discussions

Letter sent to Paul:

Could you do a little research on foundries? I put initial info up at:

http://openfarmtech.org/index.php?title=Foundry

We want to melt metal - to cast tractor, steam engine, and CEB press parts. We would like to do that this year. Are you by any chance interested in getting involved in this? The workshop will house the furnace.

If so, please research this and propose the best furnace to use. We want to work with steel - so any iron melting furnace will do. We are looking for a simple, low-cost design that can handle at least 200 pounds per hour, to be effective in casting - say the 2000 lb of a tractor frame - in one day.

The economics involved are producing $1000+ worth of structural steel for parts. This would make it economically feasible to produce tractors, etc - starting from scrap steel.

This would be quite a treat, to show fabrication starting at the cost of scrap metal. It's a possibility, but so far I have not seen an integrated operation that designs, casts, and builds under one roof. There is great potential for efficiency through this process, especially if we have global design sharing, and 3D printing of mold via open source printers such as RepRap.

Marcin

Books

- Metallurgy of Iron and Steel - [11]

- Google Book, Maximum Production in Machine-shop and Foundry - 150 lb shots in 1911 foundry took 3.5 hours - with noted low production - [12]

- Google Book, The Foundry, early 1900s, has economics - [13]

- Principles of Foundry Technology, Google Book - [14]

Induction Furnace

- Induction furnaces are well- established for the melting and holding of iron, steel, aluminum, zinc, brass, and copper. High efficiency and the ability to precisely control the rate of heat input make this electric-based technology fully competitive with alternative direct-fired processes in many applications. New developments in variable-fre- quency power supplies, improved refractory linings, high-power inductor designs, furnace heat recovery, and computer control of furnace operations offer the potential for further significant improvements in furnace effi- ciency, productivity, and in the range of materials to which - excellent overview in EPRI Center for Materials Production.

- Another overview by Fairchild Semiconductor Power Division - [15]

- Efficiencies of induction melters is 55-75% - [16]

Links

- Microwave melting - even iron - [17]

- Crucibles, furnaces, specs - [18]

- http://www.backyardmetalcasting.com/bestfurnace01.html

- Oil-fired foundry on Instructables - [19]