Power Cube v16.8: Difference between revisions

Jump to navigation

Jump to search

Tom Griffing (talk | contribs) |

Tom Griffing (talk | contribs) m (→Development) |

||

| Line 1: | Line 1: | ||

=Development= | =Development= | ||

Published the latest design in Sketchup below | Published the latest design in Sketchup below | ||

| Line 57: | Line 13: | ||

Shapshot: Suction plumbing: Use 2 suction strainers and separate hoses to pumps, as reservoir ports are only 1 1/4" and these suction strainers are only rated at 8GPM each. | Shapshot: Suction plumbing: Use 2 suction strainers and separate hoses to pumps, as reservoir ports are only 1 1/4" and these suction strainers are only rated at 8GPM each. | ||

[[Image:PC16.8SuctionPlumbing.png Suction Plumbing|600px]] | |||

==Question== | ==Question== | ||

| Line 67: | Line 25: | ||

Should we employ any special grinding / welding procedures for the one weld where all three members meet? | Should we employ any special grinding / welding procedures for the one weld where all three members meet? | ||

Revision as of 02:22, 30 August 2016

Development

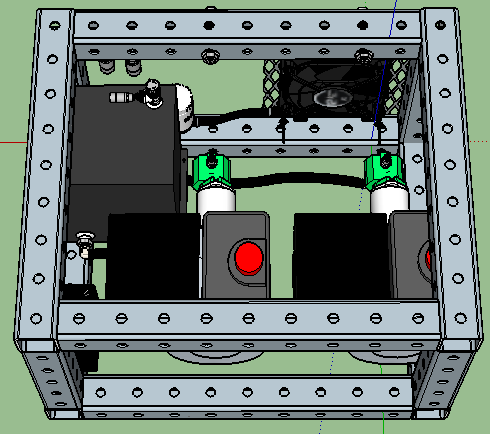

Published the latest design in Sketchup below

This design has had few updates lately. Here are the latest updates:

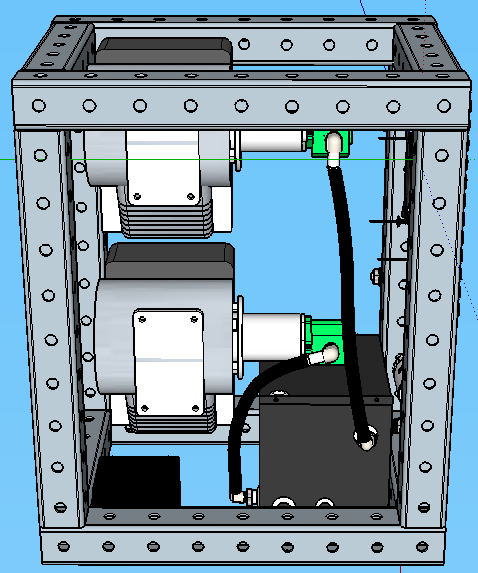

Aug 2016: Twin 18HP engine design in the works - mostly complete, will be built in the September Power Cube workshop

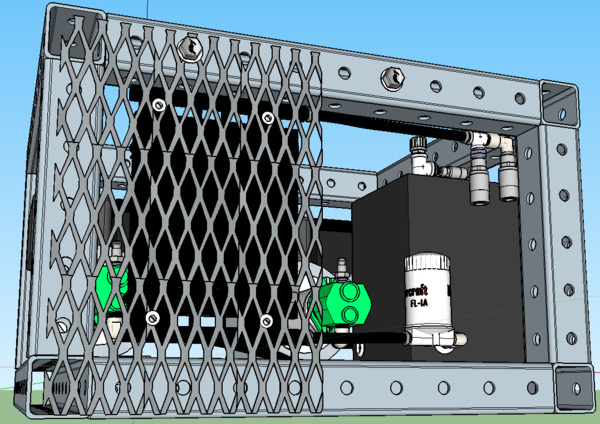

Snapshot: Hydraulic ports - 2 3/4" male outputs from the top of the pumps, 2 3/4" female returns and 1 1/4" low pressure return.

Shapshot: Suction plumbing: Use 2 suction strainers and separate hoses to pumps, as reservoir ports are only 1 1/4" and these suction strainers are only rated at 8GPM each.

Question

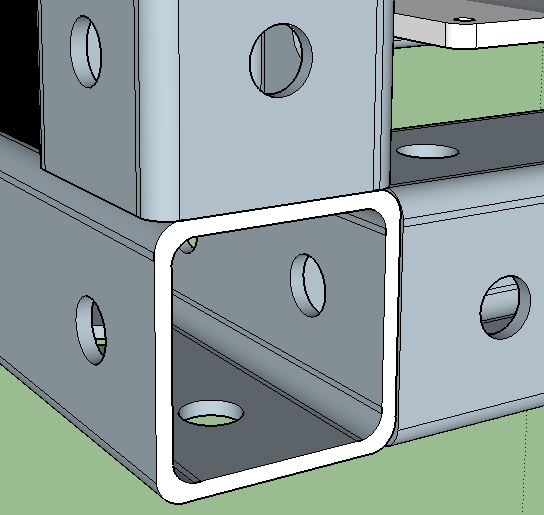

How should corners be formed and welded for optimal strength? Here is one image of a corner, with one of the horizontal members in the corner and the others welded to it:

Should the orientation be the same for all 8 corners?

Should we employ any special grinding / welding procedures for the one weld where all three members meet?