Swingblade Sawmill: Difference between revisions

Jump to navigation

Jump to search

| Line 10: | Line 10: | ||

Interestingly, with [[LifeTrac]], we can power a hydraulically-driven variant of this device. This will eliminate the engine and 90 degree gear requirements, thereby simplifying the machine greatly. The detachable, hydraulic PTO motor from LifeTrac will be the power source. We know of no other swingblades driven by hydraulics - let us know if you know of any. | Interestingly, with [[LifeTrac]], we can power a hydraulically-driven variant of this device. This will eliminate the engine and 90 degree gear requirements, thereby simplifying the machine greatly. The detachable, hydraulic PTO motor from LifeTrac will be the power source. We know of no other swingblades driven by hydraulics - let us know if you know of any. | ||

This hydraulic variant eliminates engine cost and 90 degree gear cost - reducing prototype cost respectively. | |||

==Parts== | ==Parts== | ||

Revision as of 17:25, 5 September 2008

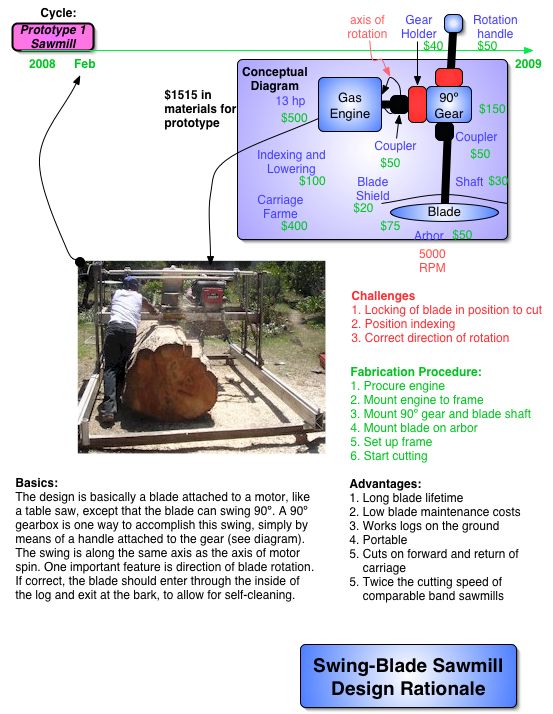

Design Rationale

Past work on band sawmill is here.

Present work (note: present development involves powering the swingblade with a detachable power take-off hydraulic motor from LifeTrac):

Hydraulic Power Variant

Interestingly, with LifeTrac, we can power a hydraulically-driven variant of this device. This will eliminate the engine and 90 degree gear requirements, thereby simplifying the machine greatly. The detachable, hydraulic PTO motor from LifeTrac will be the power source. We know of no other swingblades driven by hydraulics - let us know if you know of any.

This hydraulic variant eliminates engine cost and 90 degree gear cost - reducing prototype cost respectively.

Parts

- Lucas blades, $185