Industrial Robot Mechanical Design: Difference between revisions

(Added brief descriptions of components) |

(Added stepper motor-needle valve bracket illustration and description) |

||

| Line 41: | Line 41: | ||

In total, 6 stepper motors are required to adjust the 6 needle valves. | In total, 6 stepper motors are required to adjust the 6 needle valves. | ||

=Stepper Motor and Needle Valve Mounting Bracket= | |||

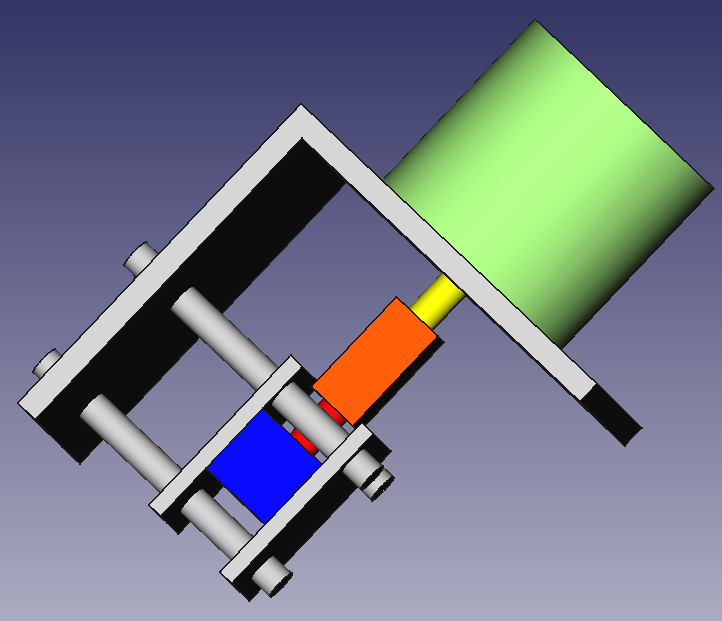

Green is stepper motor, mounted directly onto the angle piece. Yellow is the stepper motor shaft, connected directly to the pink hub. The pink hub is bolted to the orange hub, completing the shaft coupling. The orange hub is connected directly to the needle valve shaft. The blue needle valve is held between 2 plates. The 2 plates are held in place by 3 bolts that connect to the main angle piece. | |||

[[Image:Stepneedlemount.png]] | |||

=Gearbox= | =Gearbox= | ||

Revision as of 18:17, 2 June 2011

Toolchain for Toolpaths

CAD (FreeCAD) > export (stl, dxf, svg) > CAM (PyCAM) > export (gcode) > Machine Controller (EMC2) > export (logic signals) > Machine (CNC milling, various) > export (work)

In FreeCAD, a 3d mesh drawing can be exported as an stl file; alternatively, a 2d drawing can be exported as a dxf or svg file. Any of these files can then be imported in PyCAM, in which toolpaths can be generated for those drawings. These toolpaths can then be exported from PyCAM as a gcode file. EMC2 can then import the gcode file and simulate the toolpath, plus send logic signals to an external electronic controller that moves a machine to correspond to the toolpath. This toolchain allows digital fabrication to be utilized for the construction of the industrial robot.

Mechanical Concept

Hydraulic Motor

Damen Technical Agencies on Types of Hydraulic Motors

Hydraulic motors move the industrial robot at each of its 6 joints.

Possibility is epicyclic (gerotor) motors

- Joint 1 (Base Rotation) Motor: after gear reduction, required to have torque of upwards of X

- Joint 2 (Base Tilt) Motor: after gear reduction, required to have torque of upwards of X

- Joint 3 (Elbow Tilt) Motor: after gear reduction, required to have torque of upwards of X

- Joint 4 (Wrist Rotation) Motor: after gear reduction, required to have torque of upwards of X

- Joint 5 (Wrist Tilt) Motor: after gear reduction, required to have torque of upwards of X

- Joint 6 (Endeffector Rotation) Motor: after gear reduction, required to have torque of upwards of X

Stepper Motor

Stepper motors can be electronically operated and can turn the handle on needle valves; in relation, the function of the stepper motor is to allow the electronic control of needle valves.

A stepper motor can be mounted onto a bracket then connected to the needle valve adjusting handle through a shaft coupling connection. The overall design must allow for the shaft, coupling, or handle to move parallel to the shaft because the needle valve moves slightly up or down when turning in its threads.

In total, 6 stepper motors are required to adjust the 6 needle valves.

Stepper Motor and Needle Valve Mounting Bracket

Green is stepper motor, mounted directly onto the angle piece. Yellow is the stepper motor shaft, connected directly to the pink hub. The pink hub is bolted to the orange hub, completing the shaft coupling. The orange hub is connected directly to the needle valve shaft. The blue needle valve is held between 2 plates. The 2 plates are held in place by 3 bolts that connect to the main angle piece.

Gearbox

Presentation Slides on Gearbox Design

The gearbox is used to make a torque-speed tradeoff with the hydraulic motors. In this case, the speed of the hydraulic motors must be reduced and the torque increased.

By virtue of using hydraulic drive, the motor shaft speeds are low enough that we might be able to use a compact spur gearbox at each joint instead of a more complicated configuration such as harmonic drive.

The gearbox must accomodate a shaft encoder.

The gearbox must have an output shaft that is keyed and fastened to a hub; the hub will be bolted to the next frame piece in the design.

The gearbox must withstand the various kinetic forces that exist when the industrial robot is stationary or moving.

Kinematic Parameters

Wikipedia on Denavit-Hartenberg Parameters (video included)

Formal Lecture Notes on Denavit-Hartenberg

The Denavit-Hartenberg parameters define the position relationships between 2 motors of the industrial robot. More specifically, the robot has 6 motors, hence one parameter would be between motor 1 and 2; another between motor 2 and 3, 3 and 4, 4 and 5, and 5 and 6.

The Denavit-Hartenberg parameters are as follows, for joint(i): depth(i), normal length(i), z angle (i), x angle (i).

Joint(1): Depth(1)=0.2m , Normal Length(1)=0.2m , Z Angle(1)=90deg , X Angle(1)=*

Joint(2): Depth(2)=0.0m , Normal Length(2)=1.0m , Z Angle(2)=00deg , X Angle(2)=*

Joint(3): Depth(3)=0.0m , Normal Length(3)=0.1m , Z Angle(3)=90deg , X Angle(3)=*

Joint(4): Depth(4)=0.0m , Normal Length(4)=0.0m , Z Angle(4)=90deg , X Angle(4)=*

Joint(5): Depth(5)=0.2m , Normal Length(5)=0.0m , Z Angle(5)=90deg , X Angle(5)=*

where * is the joint variable

Mass

Given density of A36 steel as 0.28 pounds per cubic inch, or 7750 kilograms per cubic metre, and using numbers from the current design:

Foundation Underplate: 15.75 pounds, or 7.144 kilograms

Foundation Pillar: 11.2 pounds, or 5.08 kilograms

Foundation Pillar Angle: 0.525 pounds, or 0.238 kilograms

Foundation Overplate: 8.47 pounds, or 3.84 kilograms

Base Angle: 33.6 pounds, or 15.2 kilograms

Main Arm: 161.28 pounds, or 73.155 kilograms

Forearm: 60.48 pounds, or 27.43 kilograms

Forearm Angle: 33.6 pounds, or 15.2 kilograms

Wrist Angle: 33.6 pounds, or 15.2 kilograms

Wrist Plate: 60.48 pounds, or 27.43 kilograms

Endeffector Angle: 33.6 pounds, or 15.2 kilograms

Sum 1:The mass of the steel frame pieces of the foundation is 71.12 pounds, or 32.26 kilograms.

Sum 2: The mass of all steel frame pieces excluding the foundation is 416.64 pounds, or 188.98 kilograms.