Babington Burner: Difference between revisions

| Line 59: | Line 59: | ||

[http://pateri.com/Foundry/Burners.html] | [http://pateri.com/Foundry/Burners.html] | ||

[[Image:http://pateri.com/Foundry/pics/dsci0015.jpg]] | |||

[[Image:http://pateri.com/Foundry/pics/T-dsci0022.jpg]] | |||

=Parts Sourcing= | =Parts Sourcing= | ||

Revision as of 20:33, 30 September 2008

Introduction

This burner is important because it is a versatile source of heat for: space heating, metal melting, glassworks, pottery, steam engines for remote power, heat engines for mobile power in cars and tractors, and many others. We can use it with any waste oil - crankcase, vegetable, etc. - plus Pyrolysis Oil from Biomass once we develop it. It is not a far stretch to produce pyrolysis oil- see this simple experimental proposition. Do you think this would yield useful amounts of liquid fuel?

Background Reseach - Design Rationale

So what is the synthesis of available information regarding the Babington Burner? Wastewatts is one Yahoo group that deals with the Babington. What is the state of the art for:

- The type of ball used - size, shape (endcap with groove, ball, doorknob). Does wall thickness matter

- Do people have trouble with debris from inside the ball clogging up the ball hole? We had trouble, so we are cleaning our brass doorknow with an overnight vinegar bath.

- What is the number of holes that people have used? I've seen 1 and 2 hole versions on the internet.

- What is the hole size range? I've seen .01-.02 being used.

- What is the pressure range used?

- What is the range of flame size possible for a clean burn?

- Did anyone measure fuel usage rate and heat output in BTU or kW?

- What is the optimal pump used for active fuel pumping?

- Is there an upper limit to the desirable air pressure for the burner ball?

- What is the best type of shroud to use?

- Pipe section - what length, diameter, wall thickness?

- Air holes - what is the number and location for these?

- Ends of pipe - the flame end is open, and burner ball end is closed?

- Does anyone use forced air for additional air input?

- Applications - has anyone field-tested:

- Shop heating?

- Water heating with heat exchanger?

- Steam generation?

- Steam engine operation?

- Combined heat power applications?

- Metal melting furnace?

- Pottery kiln?

- Brickworks?

- Glassworks applications?

- Backup power generation with steam engine?

- Mobile power application in steam cars and tractors?

- Flame week killer?

- Flamethrower for parades?

- What measures need to be taken to assure the flame does not go out?

- What is the optimal temperature range for the fuel feed, and how to preheat the fuel?

- What are other issues/quirks that make the Babington unstable?

- What is the expected lifetime of a burner ball? Is this an issue?

- Is regular cleaning required, or can this system be self-cleaning in continuous burning?

- Does anyone have effective, complete system designs that we can replicate?

Internet Research

After searching for hours on details for the Babington burner, here is the best one:

http://www.aipengineering.com/babington/Babington_Oil_Burner_HOWTO.html

Here's a video that shows the clear potential of the Babington:

http://www.youtube.com/watch?v=78ebfypFLXI

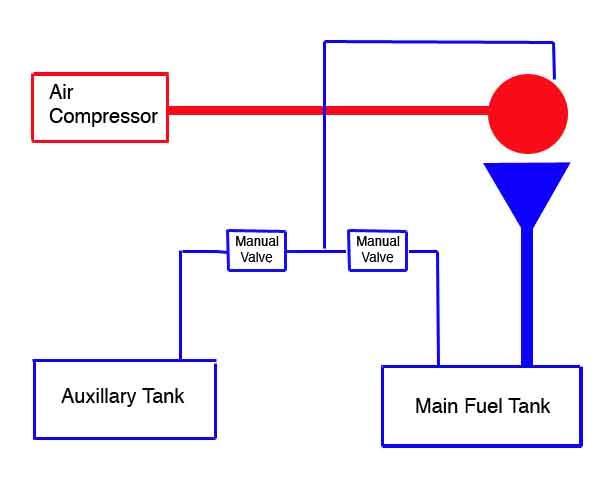

Here is several pictures of a design

File:Http://pateri.com/Foundry/pics/dsci0015.jpg

File:Http://pateri.com/Foundry/pics/T-dsci0022.jpg

Parts Sourcing

Other Implementations

- From [4]

- Video on Youtube - [5]

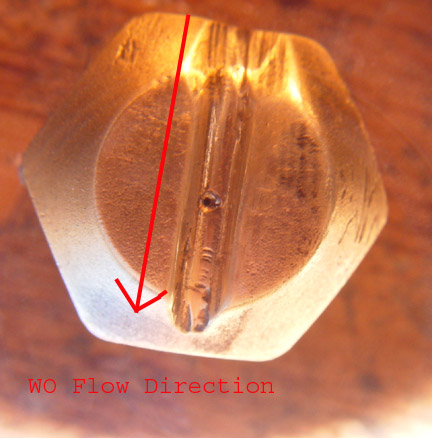

Burner Ball

Here is a brass endcap with a channel for directing oil flow:

Does this work better than a ball?

Implementation at Factor e Farm

On 9.29.08 we started to put together our Babington burner.

We drilled a 0.0135 inch hole in the face of a hollow, brass doorknob - and brazed on a fitting that supplied compressed air at a constant pressure between 20-35 psi. We were able to atomize water but when we tried motor oil we had problems. We were able to produce a bit of a flame but never sustained burning. Two possibilities: 1) the hole became clogged from debris inside the burner ball, 2) the oil was not heated sufficiently. Has anyone had success in sustaining a flame over a long period? What is a good method for automatic ignition? Best way to regulate the flow over the ball? Any feedback is welcome from experienced Babsmen.

Technique: we attached a rotary tool to a regular drill press - to utilize the up-down motion of the drill press with the rototool as the work tool for the .0135 micro drill bit.

Water atomization was successful, seen in the last picture. Fuel atomization was not.

Next steps: heat oil properly - for now on a stove top, and use a metal dispenser container. Clean out the inside of the burner ball.

Results to be posted evening of 9.30.08: