Steam Engine Planning: Difference between revisions

Jump to navigation

Jump to search

| Line 11: | Line 11: | ||

*About 150 rpm | *About 150 rpm | ||

*Use stock piston seals | *Use stock piston seals | ||

*Machining boils down to lathing piston seal grooves | *Machining boils down to lathing piston seal grooves | ||

*Connecting rod threaded into piston, uses two nuts | *Connecting rod threaded into piston, uses two nuts | ||

*Use flywheel and linkage | |||

=Strategy= | =Strategy= | ||

Revision as of 02:26, 8 December 2008

Concept Introduction

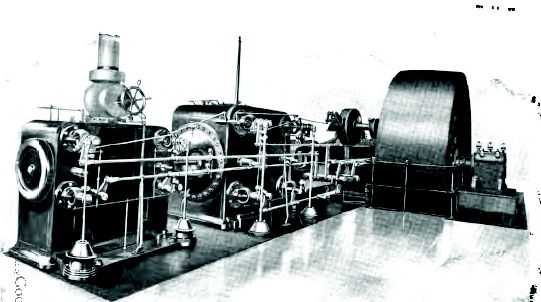

Nick Raaum is project manager. Our present concept is to use a single acting cylinder made from steam piping, using an electronically-controlled valve, and a position sensor that tells when the valve should open and close.

Design Rationale

- Use stock pipe section for replicability

- Welded ends

- Flywheel and pulley is used

- About 150 rpm

- Use stock piston seals

- Machining boils down to lathing piston seal grooves

- Connecting rod threaded into piston, uses two nuts

- Use flywheel and linkage

Strategy

On 12.6.08, Nick and Marcin had a strategy session in which we decided:

- Pursue a simple, single-acting, steam engine with electronically controlled valve

- Pursue stock pipe sections to eliminate casting requirements?

Electronics

- Asco valve - 8 hz, 150 PSIg operating pressure solenoid steam valve - $100 new; one required

- Programmable Logic Controller - Arduino board?

- Position sensor - an optical sensor, photoelectric eye?

Materials

- A56 Schedule 80 half inch piping, carbon steel