CEB 3D Printer: Difference between revisions

No edit summary |

mNo edit summary |

||

| Line 165: | Line 165: | ||

| | ||

</pre> | </pre> | ||

<html> | |||

<head> | |||

<meta content="text/html; charset=ISO-8859-1" | |||

http-equiv="content-type"> | |||

<title>pageEncoders</title> | |||

</head> | |||

<body> | |||

<p class="MsoNormal"><b style=""><span style="font-size: 14pt;">How do | |||

you get “cable length” from encoders?<o:p></o:p></span></b></p> | |||

<p class="MsoNormal"><o:p></o:p>Encoders gives feedback on incremental | |||

position and direction | |||

only, from which you can find velocity, acceleration, total distance | |||

travelled, | |||

etc.<span style=""> </span>However, you don’t have a <u>reference | |||

point</u> for starting out: meaning that as soon as the software is | |||

powered on, | |||

and the actuators start moving you may have travelled 0.5234’.<span | |||

style=""> </span>But from where?</p> | |||

<p class="MsoNormal"> | |||

<o:p></o:p></p> | |||

<p class="MsoNormal"><o:p></o:p><u>Home position sensors</u> are used | |||

by triggering a sensor/switch | |||

at a pre-determined location so that after the sensor is tripped, the | |||

length is | |||

recorded and all movements originate from that length.<span style=""> | |||

</span></p> | |||

<p class="MsoNormal"> | |||

<span style=""> </span><o:p></o:p></p> | |||

<p class="MsoNormal"><o:p></o:p>This can be as simple as releasing all | |||

3 motors, and pulling | |||

on one until the gripper is 1 foot length from, the top pulley – a | |||

location | |||

where it will never be in normal operationally.<span style=""> | |||

</span>An attachment connected that flips a switch.<span style=""> | |||

</span>Once flipped, measure the actual physical location | |||

and this becomes a constant in software.</p> | |||

<br><br> | |||

<p class="MsoNormal"><big><span style="font-weight: bold;">An Example:</span></big><br> | |||

<o:p></o:p></p> | |||

<p class="MsoNormal"><o:p></o:p>Let’s say that this encoder (from | |||

omron.com ) with a <b style="">40mm external shaft diameter</b> and a <b | |||

style="">resolution of 300 pulses/rotation</b> is used.<o:p></o:p></p> | |||

The <b style="">Home position | |||

sensor routine</b> runs for each motor.<span style=""> </span><o:p></o:p> | |||

<p class="MsoNormal">Let’s say the encoders are mounted so that there | |||

they spin | |||

from the friction on the cable, without-slipping.<span style=""> </span>If | |||

the cable moves in the releasing direction | |||

<span style="font-weight: bold;">one foot</span> in length, the encoder | |||

spins this direction:<span style=""> <br> | |||

</span></p> | |||

<br> | |||

<p class="MsoNormal"><br> | |||

</p> | |||

</body> | |||

</html> | |||

<u>'''The example in Code:'''</u> | |||

<html> | |||

<pre><span style="color: rgb(126, 126, 126);">// 1 millimeter = 0.0032808399 feet</span><br><br>mm2ft = 0.0032808399; <span style="color: rgb(126, 126, 126);">// conversion variable</span><br>counts_per_rev = 300;<br><br>diameter = 40; <span style="color: rgb(126, 126, 126);">// mm</span><br>diameter = 40*mm2ft; <span style="color: rgb(126, 126, 126);">// convert shaft to ft.</span><br><br>circumference = diameter*pi;<br><br>distance_per_rev = circumference<br><br><span style="color: rgb(126, 126, 126);">//******************************************************//</span><br><span style="color: rgb(126, 126, 126);">// Example: distance = 1 ft. how many counts are recorded?</span><br><br>distance = 1;<br>counts = (counts_per_rev)*(1/distance_per_rev)*distance<br><br><span style="color: rgb(126, 126, 126);">// counts =</span><br><span style="color: rgb(126, 126, 126);">// </span><br><span style="color: rgb(126, 126, 126);">// 727.66</span><br><br><span style="color: rgb(126, 126, 126);">// rounded down to 727 as counts are integers</span><br><br><span style="color: rgb(126, 126, 126);">// Example: counts = 3200. How much distance travelled?</span><br><br>counts = 1000;<br>distance = (distance_per_rev)*(1/counts_per_rev)*counts<br><big><br><span style="color: rgb(126, 126, 126);">// distance =</span><br><span style="color: rgb(126, 126, 126);">// </span><br><span style="color: rgb(126, 126, 126);">// 1.3743 (feet)</span></big><br><br><span style="color: rgb(126, 126, 126);">//******************************************************//</span><br><br></pre> | |||

</html> | |||

Revision as of 19:03, 20 December 2011

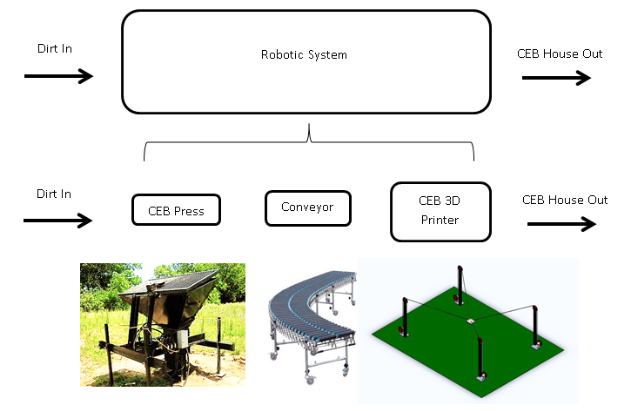

Concept (Illustrated Below): This idea is to develop an automated brick-laying system that can build homes from the ground up, literally. Using a combination of the CEB Press, a conveyor belt, gripper, and a common machine configuration (TBD), the machine acts like a large 3D printer which picks and places compressed bricks robotically.

Two video animations, originally made as Java applets, illustrate two such designs:

Animation (Gantry Design)

Animation (Cable Design)

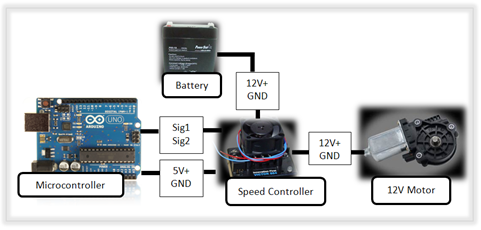

High-Level Actuator Architecture:

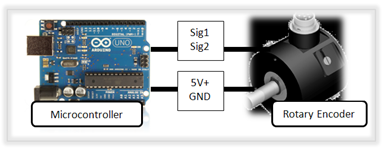

High-Level Feedback Architecture:

Sample Source Code:

|

Pseudo Code

|

Arduino Code |

| DECLARE VARIABLES & FUNCTIONS Initialize Output Channels // Tell microcontroller which pins are output Initialize Input Channels // Tell microcontroller which pins are input MAIN LOOP For Motors 1 to 4: Read Encoder Values Calculate Motor Output to Achieve Desired Position Write to Motor Output Channel // Note: the motor signal is sent to a speed controller // to be amplified END FOR LOOP END MAIN LOOP |

void setup() { pinMode(2, OUTPUT); // to Base motor 1 pinMode(3, OUTPUT); // to Base motor 2 pinMode(4, OUTPUT); // to Base motor 3 pinMode(5, OUTPUT); // to Base motor 4 pinMode(6, INPUT); // from digital Encoder 1 pinMode(7, INPUT); // from digital Encoder 2 pinMode(8, INPUT); // from digital Encoder 3 pinMode(9, INPUT); // from digital Encoder 4 } void loop() { for (int motorIndex = 0; motorIndex < 3; motorIndex++) { read_encoders(); pid(); write_to_motors(); } } |

FUNCTION NAME:

INPUT TO FUNCTIONS

OUTPUT OF FUNCTIONS

*: unfinished or incorrect function, will change within a week.

Read Encoders Function: Read digital encoders and scale the value accordingly to return current length in feet. This function will need to be written after testing is done, but I can provide skeleton code soon.*

How do

you get “cable length” from encoders?

An Example:

The Home position sensor routine runs for each motor.

Let’s say the encoders are mounted so that there

they spin

from the friction on the cable, without-slipping. If

the cable moves in the releasing direction

one foot in length, the encoder

spins this direction:

The example in Code:

// 1 millimeter = 0.0032808399 feet

mm2ft = 0.0032808399; // conversion variable

counts_per_rev = 300;

diameter = 40; // mm

diameter = 40*mm2ft; // convert shaft to ft.

circumference = diameter*pi;

distance_per_rev = circumference

//******************************************************//

// Example: distance = 1 ft. how many counts are recorded?

distance = 1;

counts = (counts_per_rev)*(1/distance_per_rev)*distance

// counts =

//

// 727.66

// rounded down to 727 as counts are integers

// Example: counts = 3200. How much distance travelled?

counts = 1000;

distance = (distance_per_rev)*(1/counts_per_rev)*counts

// distance =

//

// 1.3743 (feet)

//******************************************************//

Calculate Length Function: Now that desired gripper position & all 4 current lengths are known, desired length for each cable can be calculated.*(current length is already known actually from previous function, will update code soon)

float px, py, pz; // p (x,y,z) is the current position of the gripper float dpx, dpy, dpz; // p (x,y,z) is the desired position of the gripper float Bheight = 12.0, Blength = 18.0, Bwidth = 12.0; // Base dimensions at 12'x18'x12' float B1x = 0.0, B1y = 0.0, B1z = Bheight; // top point of base rod 1 float B2x = 0.0, B2y = Blength, B2z = Bheight; // top point of base rod 2 float B3x = Bwidth, B3y = Blength, B3z = Bheight; // top point of base rod 3 float B4x = Bwidth, B4y = Blength, B4z = Bheight; // top point of base rod 4 float L1,L2,L3,L4, dL1,dL2,dL3,dL4; // Current and desired length variables // This function calculates the length that each of the cables // must be in order to attain the desired gripper position. void get_lengths() { // Lengths are determined from top of base rod to gripper, // so this does not include length from motor to pulley // at the top of the rod. L1 = dist3d(B1x, B1y, B1z, px,py,pz); // Length of cable 1 in feet L2 = dist3d(B2x, B2y, B2z, px,py,pz); // Length of cable 2 in feet L3 = dist3d(B3x, B3y, B3z, px,py,pz); // Length of cable 3 in feet L4 = dist3d(B4x, B4y, B4z, px,py,pz); // Length of cable 4 in feet // Desired lengths calculated the same way. dL1 = dist3d(B1x, B1y, B1z, dpx,dpy,dpz); // Desired length of cable 1 dL2 = dist3d(B2x, B2y, B2z, dpx,dpy,dpz); // Desired length of cable 2 dL3 = dist3d(B3x, B3y, B3z, dpx,dpy,dpz); // Desired length of cable 3 dL4 = dist3d(B4x, B4y, B4z, dpx,dpy,dpz); // Desired length of cable 4 } //____________CALCULATE_THE_3-D_DISTANCE_(L-3_NORM)________________// float dist3d(float p1x, float p1y, float p1z, float p2x, float p2y, float p2z) { float dist3 = sqrt((p2x-p1x)*(p2x-p1x) + (p2y-p1y)*(p2y-p1y) + (p2z-p1z)*(p2z-p1z)); return dist3; }

PID Function: Now that desired length and current length are known, motor output and direction for each motor can be calculated.

float[] err = new float[4]; // error array float[] dir = new float[4]; // direction array float[] out = new float[4]; // output array float kp = 500; // this gain is arbitrary, but must be positive float Prop; // Variable used for proportional gain. float max_output = 100; // Saturate the output at 100, also arbitrary //___________________PID_FUNCTION______________________// void pid() // Actually just P for simplicity's sake { Prop = kp*err[motorIndex]; // P = const*(desired_length - current_length) out[motorIndex] = Prop; // output = P; if (out[motorIndex] > 0) dir[motorIndex] = 1; // Get direction either 1 else dir[motorIndex] = 0; // or 0 constrain(out[motorIndex], -max_output, max_output); // saturate output out[motorIndex] = abs(out[motorIndex]); // now that we know direction, we // just need the absolute output }

Write to Motors Function: Digital write to speed controllers (output is amplified using the higher current & voltage power source from 12V batteries. This function, just like the encoders will need to be written after/while testing is done, but I can provide skeleton code soon. *

PHASE 1: Proof-of-Concept (5-10 people)

1. Gripper Design

a.) Research what's available for this application in terms of ballpark specs and power requirements, decide if feedback is necessary

b.) Actuator Selection: motors/servos

c.) Produce CAD of all mechanical parts

2. Mechanical Design (ideally 2 people should be on this)

a.) Research materials

b.) Produce CAD models and assembly

c.) Perform FEA and verify deflection assumptions based on realist forces and prescribed displacement: i.e., if using Aluminum and part is being stretched laterally, how much does it deflect? If greater than 1 cm, redesign, consider alternative material, or simply account for this in software.

d.) Bill of materials

3. Communication to gripper

a.) Wireless would be nice: http://www.sparkfun.com/tutorials/128, research and justify selection of technology to go with.

b.) Test at least one solution once purchased for range and loss of communication.

c.) Find what data needs to be sent and how often (actually this is probably easy, could be as simple as grip/ungrip 10 Hz - not bad)

Goal: be able to manually input single position coordinates, e.g. (x,y,z)=(4.213',5.9234',1.512') and measure how accurate and consistent system is, i.e. is it biased to one side at a higher level? Can mechanical shortcomings be remedied in software.

PHASE 2: Scaling up and adding complexity

4. Data input - Using XML or .txt file, pass in from PC to microcontroller via serial connection a list of coordinates.

a.) Write program to design a structure & output XML file - the one complication here is to post-process the solid and write sub-routines to convert solid into something to be completely built from bricks.

i.) Tutorial on how to do so

ii.) Generate at least 2 sample files.

b.) Write program to read XML file and send to microcontroller

c.) Arduino sub-routine to read in data.

5. A simple control board for translational speed, display number of brick, start, stop, etc.

6. Base Mobile Platform - http://www.robotcombat.com/store_tanktreads.html either tank treads or wheels

a.) Research

b.) CAD

c.) Integration with current software

IRC Online Meeting Schedule: This is temporary section I'm experimenting with which doesn't quite belong here.

IRC Experimental Meeting Test Chart: This chart is used to display group meeting times on the OSE Internet Relay Chat (IRC) http://opensourceecology.org/wiki/Irc where groups can discuss project ideas and progress with realtime feedback. Group member names, IRC chat usernames, and status of sub-projects are listed.

| Task | Name/Pseudonym | IRC Username | Status of Project | Extra |

|---|---|---|---|---|

| Motor Testing | vc_nepo | vc_nepo | 10 % | Link |

| Encoder | User B | userBonIRC | 20 % | |

| Material Spec | User C | userConIRC | Complete |