Vegetable Oil Production: Difference between revisions

mNo edit summary |

|||

| Line 27: | Line 27: | ||

The cage press method of expressing oil involves loading seed into a squeezing compartment, applying at least 500psi to crush seed and express the liquid oil, then removing the remaining solid oilcake. It seems that with appropriate simple modifications (wall perforations in the upper end of the compression chamber) the [[CEB_Press |CEB Press]] could perform this function very effectively. | The cage press method of expressing oil involves loading seed into a squeezing compartment, applying at least 500psi to crush seed and express the liquid oil, then removing the remaining solid oilcake. It seems that with appropriate simple modifications (wall perforations in the upper end of the compression chamber) the [[CEB_Press |CEB Press]] could perform this function very effectively. | ||

[[Category: Food_And_Agriculture]] | |||

Revision as of 07:49, 13 February 2012

Overview

OSE principles suggest minimal use of petroleum products, which often means the substitution of locally produced vegetable oils. Oil crops are also likely to be grown for edible cooking oils. In either case, appropriately-scaled oil processing technology is required.

Applications

- Cooking oil

- Hydraulic fluid

- Motor fuel (Biodiesel)

- Lubricating oil (e.g. [1][2])

- Paints/coatings

- Electrical dielectric fluid[3]

Crops

Process

Small scale processing paper from ATTRA

Oilseed pressing on Appropedia

Description of conventional Refined/Bleached/Deodorized(RBD) process in this patent application

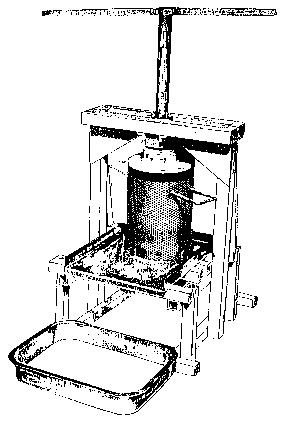

The cage press method of expressing oil involves loading seed into a squeezing compartment, applying at least 500psi to crush seed and express the liquid oil, then removing the remaining solid oilcake. It seems that with appropriate simple modifications (wall perforations in the upper end of the compression chamber) the CEB Press could perform this function very effectively.