Cold Saw/V1 Design Rationale: Difference between revisions

< Cold Saw

Jump to navigation

Jump to search

| Line 69: | Line 69: | ||

*'''Center-to-Center Distance Between Support Block Screws: 55mm''' | *'''Center-to-Center Distance Between Support Block Screws: 55mm''' | ||

*'''Center-to-Center Distance Between Vise Shaft and Threaded Rod: 95mm''' | |||

=Block to Baseplate Mounting= | =Block to Baseplate Mounting= | ||

Revision as of 18:20, 2 June 2012

Basic Concept

A blade rotates. The blade moves into and cuts a material.

Features

- Hydraulic Direct Drive (to provide high torque and low speed operation without complex transmission)

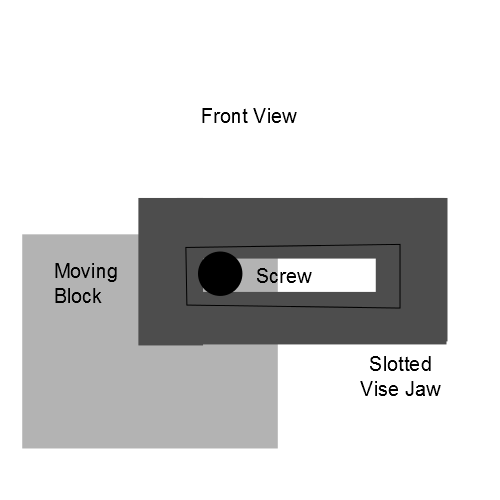

- Auto-Centering Vise (to improve cut quality)

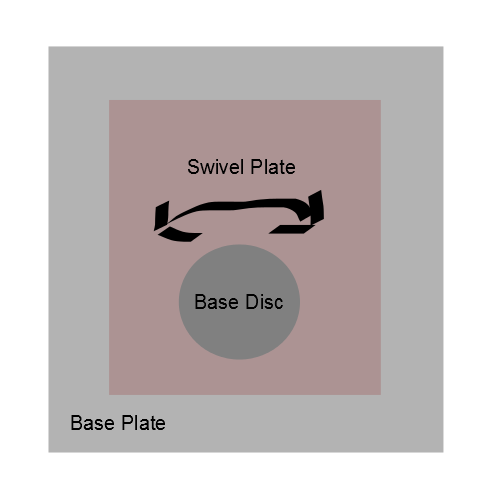

- Swivel Head (to allow angled cuts)

- Adjustable and Removable Vise Jaws (to accommodate variety of workpiece shapes and dimensions)

- Fixed Blade Guard (to protect against unintended blade contact during operation)

- Forward and Backward Drive Stops (to prevent cutting into vise and to hold blade in mid-air while mounting the workpiece)

Uniform Part Dimensions

- Plate: 457.2mm x 25.4mm

- Large Flat Bar: 25.4mm x 127mm

- Medium Flat Bar: 3.175mm x 25.4mm

- Small Flat Bar: 1.6mm x 152.4mm

- Very x2 Large Round Bar: 203.2mm DIA

- Very Large Round Bar: 127mm DIA

- Large Round Bar: 50.8mm DIA

- Medium Round Bar: 31.8mm DIA

- Small Round Bar: 8mm DIA

- Setscrew: M8x1.25 THREAD

- Bolts and Nuts: M12x1.75 THREAD

- Threaded Rod: 1-1/4"-7 THREAD

Uniform Mounting Dimensions

- Base Disc Mounting Rectangle Sides: 60mm x 110mm

- Vise Mounting Rectangle Sides: 40mm x 90mm

- Center-to-Center Distance Between Support Block Screws: 55mm

- Center-to-Center Distance Between Vise Shaft and Threaded Rod: 95mm

Block to Baseplate Mounting

- Permanent mounting methods include welding.

- Modular mounting methods include:

Bolt into countersinked baseplate hole into block hole into nut.

Screw into countersinked baseplate hole into tapped block hole.

Screw into block hole into tapped baseplate hole.

- Precision is achieved with tapped holes, and for ease of manufacturing, non-countersink methods are better.

Screw into block hole into tapped Baseplate hole Selected

Threaded Rod and Shafts Radial and Axial Hold

- The shafts can be radially supported by inserting through a block at each end; axially supported by shaft collars at each end on the outside of the blocks.

- The threaded rod does not require much radial support as the shafts handles the brunt of it. Axial load is handled by thrust washers or bearings to be mounted between the blocks and shaft collars on the ends of the threaded rod.

Shaft Collars and Thrust Washers Selected

Operation Shaft Precision Axial Hold

- The Operation Shaft uses shaft collars to precisely hold the Motor Plate and Support Plate.

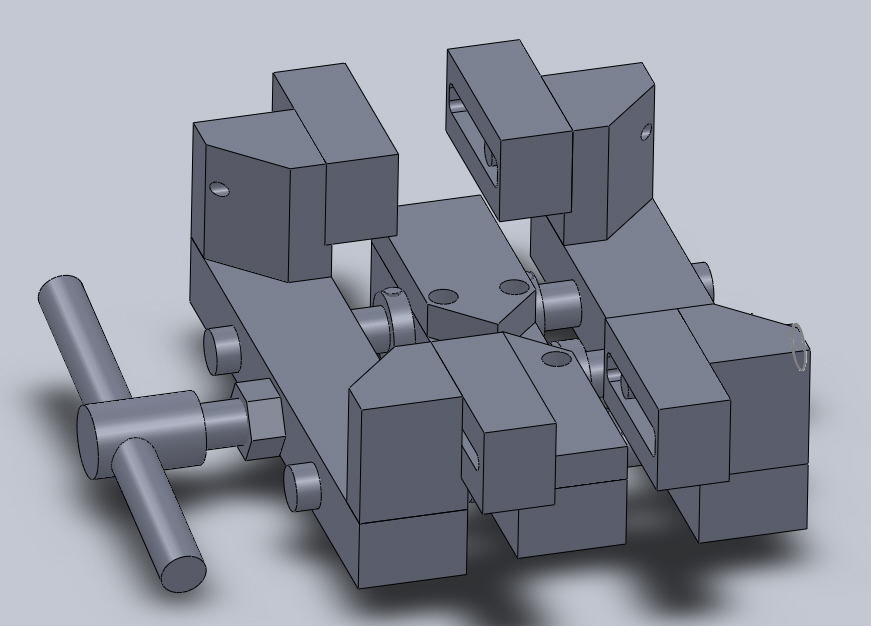

Clamp System

- The Fixed Block has 4 holes to mount itself to the Baseplate.

- The Fixed Block and Moving Blocks have 3 holes to mount the 2 Shafts and 1 Threaded Rod.

- The Shafts are held to the Fixed Block with 2 Shaft Collars each.

- The Threaded Rod is held to the Fixed Block with 2 Thrust Washers and 2 Shaft Collars.

- The Clamp Jaws have a recessed slot to mount to the Moving Blocks with 1 fastener each.

Clamp Threaded Rod and Shafts Positioning

- The workpiece must be secure during operation.

Therefore the cut must occur near the center of the clamping volume.

- The blade must not contact the Threaded Rod at any cut angle. The Threaded Rod is at the center of the clamping volume.

Therefore a space must exist between the blade bottom-out and Threaded Rod at all cut angles.

- We want the clamp volume to be as close to the Baseplate as possible for minimizing material usage and improving Fixed Block rigidity. Lower height of blade bottom-out permits lower working volume, hence allows the clamp volume to be designed closer to the Baseplate. Below the blade bottom-out plane must be a space, then the Threaded Rod.

Therefore the Threaded Rod must be mounted as close to the Baseplate as possible.

- The shafts must balance the Threaded Rod's driving force and the workpiece's reaction force such that the Threaded Rod and Moving Block do not bend.

Therefore the Shafts must be mounted between the middle of the Threaded Rod and the middle of the clamp volume's height.

Support System

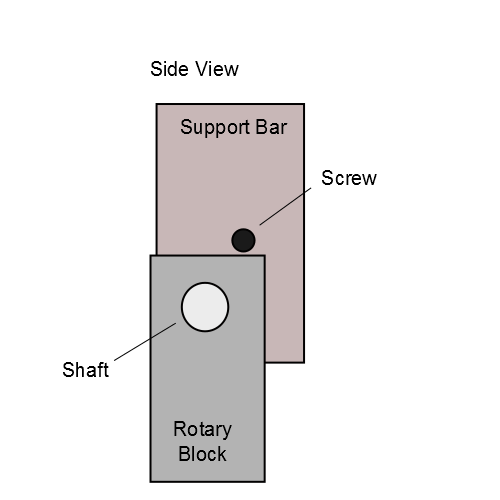

- 2 Shaft Blocks radially support the ends of the Support Shaft.

- The Support Shaft is axially held by shaft collars on its outside ends.

- The Support Shaft has thrust washers on its inside ends.

- The Main Bar and Support Bar are mounted on the Support Shaft between the thrust washers.

- The Bridge Bars span the Main Bar and Support Bar to connect them and add rigidity.

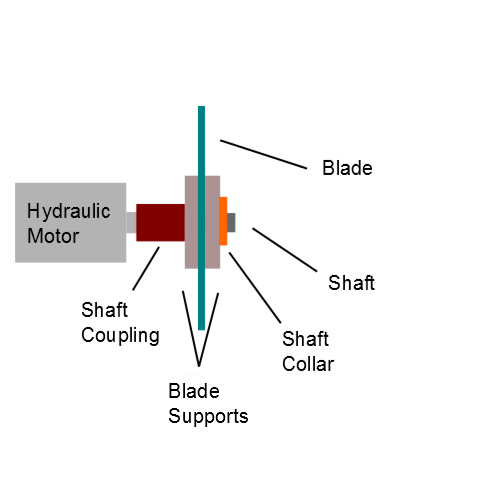

Drive System

- The Interface Plate connects the drive assembly to the rest of the frame.

- The Hydraulic Motor drives the Shaft Coupling with a setscrew and keyway connection.

- The Shaft Coupling transfers kinetic energy from the Hydraulic Motor into the Spindle.

- The Spindle is welded inside the Shaft Coupling and is threaded on its active end for nut fastening.

- The Mount Disc is welded to the active face of the Shaft Coupling and has a pinhole pattern for the Blade.

- Another Mount Disc fits into the spindle and has a pinhole pattern for the Blade.

- The Pins are welded into the pinholes of the non-welded Mount Disc.

- The Blade is sandwiched by 2 Mount Discs and its operation torque is ensured by the Pins of the outer Mount Disc.

- The Operation Handle is welded to the Interface Plate to allow the operator to easily move the drive assembly.

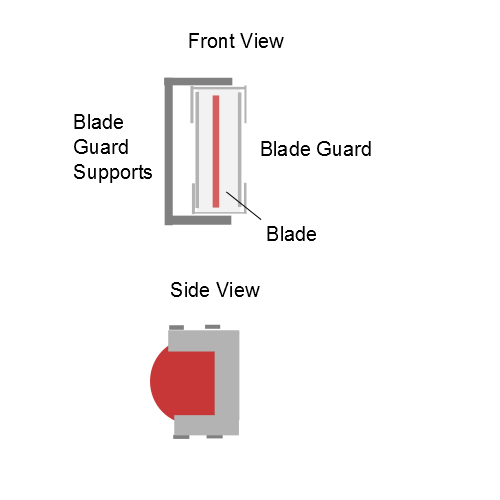

- The Blade Guard is mounted to the Interface Plate for safety during operation. The Blade Guard setup consists of a bent flat bar fastened to the Interface Plate at its middle then fastened at its ends to a thinner flat bar that bends around about half of the blade circumference.