Cold Saw/V1 Design Rationale/Movement System: Difference between revisions

Jump to navigation

Jump to search

No edit summary |

No edit summary |

||

| Line 1: | Line 1: | ||

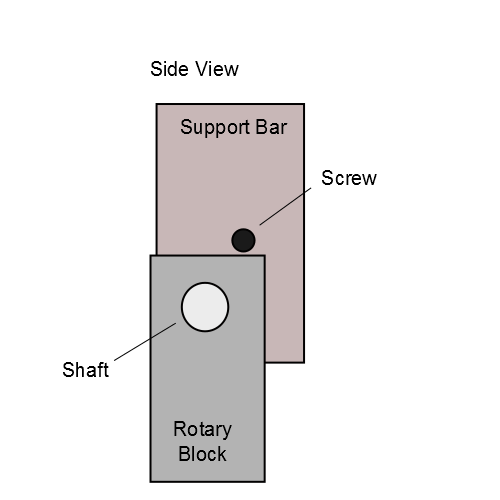

*'''Rotary Shaft and Support''' | *'''Rotary Shaft and Support''' allows the blade to descend in an arc on the workpiece. | ||

*'''Swivel | |||

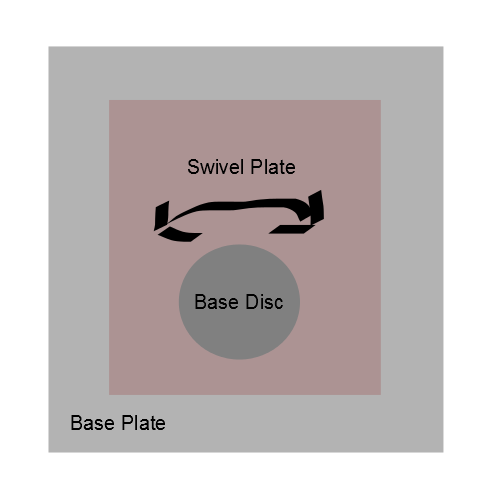

*'''Swivel Mechanism''' allows angled cuts. | |||

The swiveling frame should swivel about the centre of the vise such that the blade descent always bottoms out at the vise. | |||

The swiveling frame should be attached to a rod at the swivel centre such that the design leaves modularity for automatic encoded swivel in the future. | |||

For manual versions, the rod of the swiveling frame can be threaded so as to fasten with a nut. | |||

[[Image: ColdSawV1SwvHead.png]] | [[Image: ColdSawV1SwvHead.png]] | ||

Revision as of 16:35, 11 June 2012

- Rotary Shaft and Support allows the blade to descend in an arc on the workpiece.

- Swivel Mechanism allows angled cuts.

The swiveling frame should swivel about the centre of the vise such that the blade descent always bottoms out at the vise.

The swiveling frame should be attached to a rod at the swivel centre such that the design leaves modularity for automatic encoded swivel in the future.

For manual versions, the rod of the swiveling frame can be threaded so as to fasten with a nut.

Notes: The swivel clamp fastener should be mounted such that the swivel plate is horizontally clamped to the base disc. If the fastener is vertically mounted, then clamping the swivel head can cause bending that reduces the precision of the Cold Saw.

Feature: Forward and Backward Drive Stops

- Forward and Backward Drive Stops (to prevent cutting into vise and to hold blade in mid-air while mounting the workpiece)