Tooling Plate: Difference between revisions

(→Build) |

(→Build) |

||

| Line 41: | Line 41: | ||

---- | ---- | ||

Use [[Edge Finder]] to zero the y axis at the edge of the iron plate | |||

[[File: edgefinder.jpg|200px]] | |||

[[File: zeroed.jpg|200px]] | |||

Use [[Roughing Endmill]] on [[Mill]] (1/2" dia 4 flute); make slots; firmly lock the height for this entire step. | Use [[Roughing Endmill]] on [[Mill]] (1/2" dia 4 flute); make slots; firmly lock the height for this entire step. | ||

Revision as of 18:28, 16 November 2012

Introduction

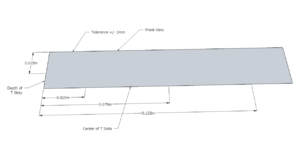

Design

Holes

Mounting interface to machine? Assuming screw-down.

Tools

Roughing Endmill - 1/2" dia - Mcmaster Carr 8817A52

T-slot Cutter - for 1/2" bolts - Mcmaster Carr 8789A12

Materials

Grey Iron - 1.25" x 6.25" x 12" - Mcmaster Carr 8923K671 OR Speedymetals

Build

Start with 1.25" x 6.25" x 12" cast grey iron plate

Use Roughing Endmill on Mill (1/2" dia 4 flute); even out the top and bottom surfaces; firmly lock the height for this entire step.

Use Surface Grinder to surface grind top and bottom faces to be parallel.

Use Edge Finder to zero the y axis at the edge of the iron plate

Use Roughing Endmill on Mill (1/2" dia 4 flute); make slots; firmly lock the height for this entire step.

Use T-slot cutter on mill. (31/32" Cutter Dia, 25/64" W Face)

Match or be a bit less than the depth of the slot; firmly lock the height for this entire step.

File:Tslottedgreyironplate.jpg

Drill? Tap?