Cory Shenk's Log: Difference between revisions

Cory Shenk (talk | contribs) No edit summary |

Cory Shenk (talk | contribs) No edit summary |

||

| Line 3: | Line 3: | ||

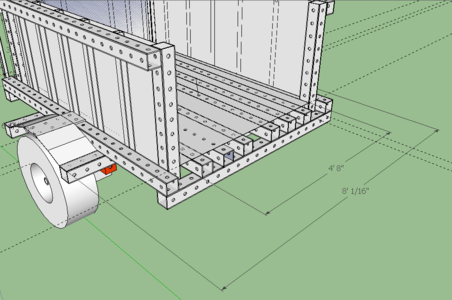

Most recent file of the truck's rear design: | Most recent file of the truck's rear design: | ||

*[[File:Shenk truck back.skp]] | *[[File:Shenk truck back.skp]] | ||

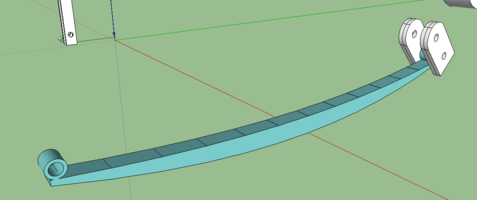

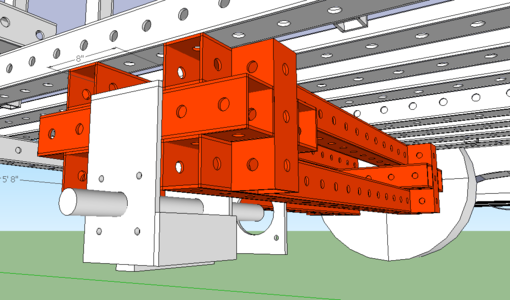

[[File:Truck LeafSpring.PNG|x200px|June 7, 2013]] | |||

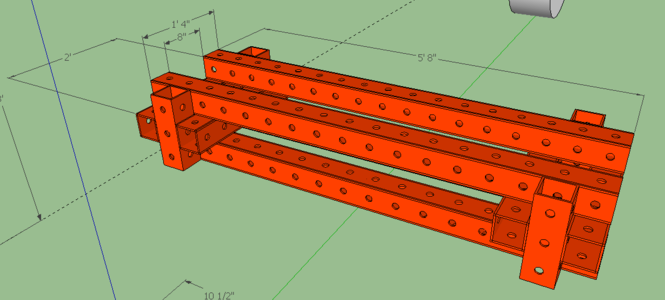

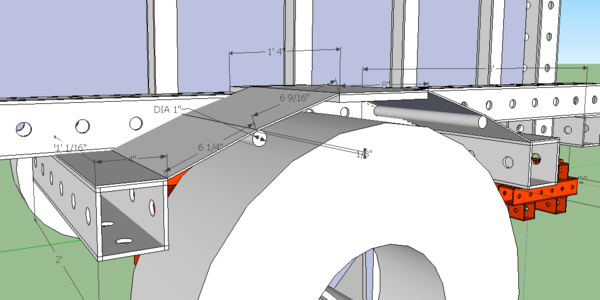

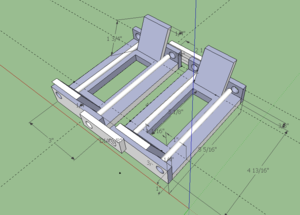

*Shows the leaf spring with the leaf spring attachment component. Note that the attachment component is doubled up. | |||

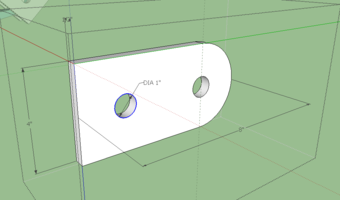

[[File:Truck LeafSpring attachment.PNG|x200px|June 7, 2013]] | |||

*Adjusted one of the pieces from the warehouse. The square ends that were there would have interfered with the flooring of the bed. When used to attach the leaf spring this component is doubled up; two on each side and then bolted to the frame of the truck. | |||

Revision as of 22:23, 7 June 2013

June 7, 2013: Truck(Rear)

Most recent file of the truck's rear design:

- Shows the leaf spring with the leaf spring attachment component. Note that the attachment component is doubled up.

- Adjusted one of the pieces from the warehouse. The square ends that were there would have interfered with the flooring of the bed. When used to attach the leaf spring this component is doubled up; two on each side and then bolted to the frame of the truck.

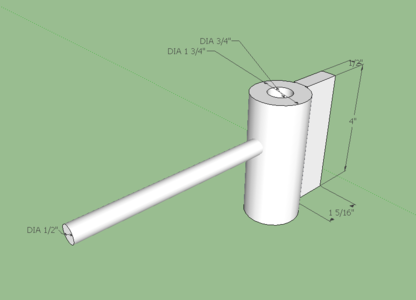

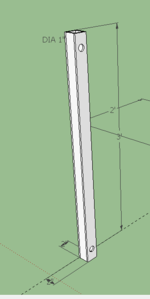

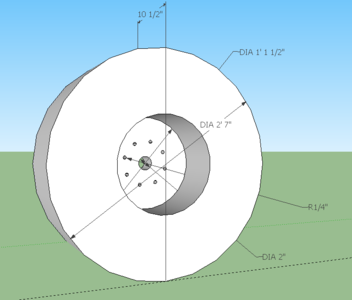

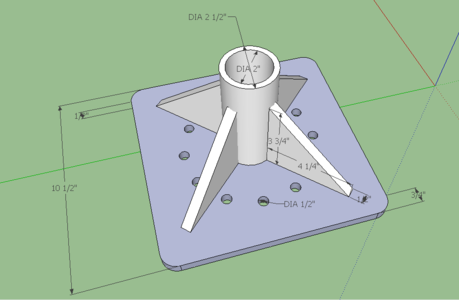

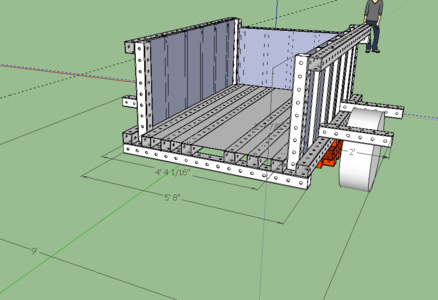

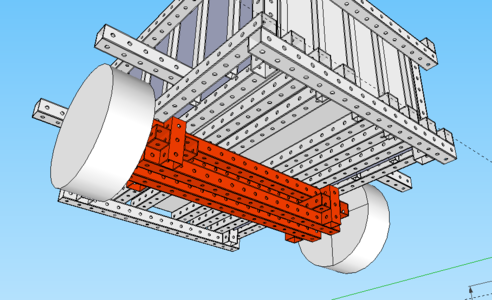

Created this piece based off of what I found on the LifeTrac in the shop. This spacer will keep the Quick Attach wheel mounts from moving in and out. The rod projecting horizontally from the vertical tube would be rebar, its purpose being to hold the piece in its proper place as it is bolted in. Many of the measurements are variable and could be easily adjusted to whatever material is available at the time.

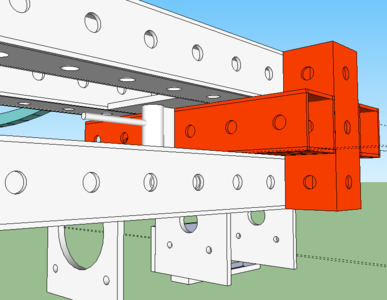

- I had to modify the rear of the truck to match with the joint that Jordan is designing. This allowed me to make the bed wider which provides more room for hauling more material.

- Here is the current SketchUp file for the rear of the truck. It includes all the various components and their dimensions. File:Shenk truck back.skp

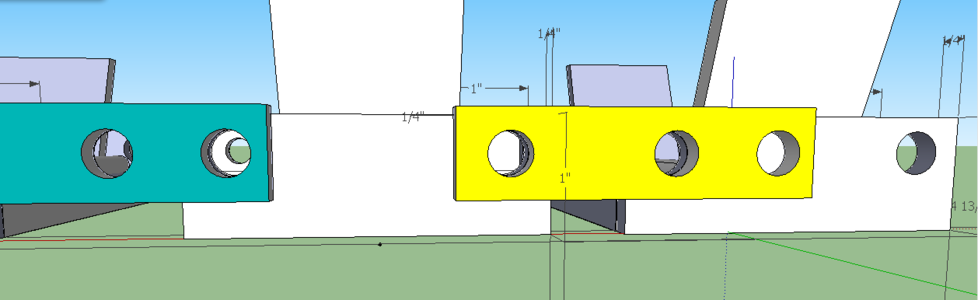

June 7, 2013: MicroTrac

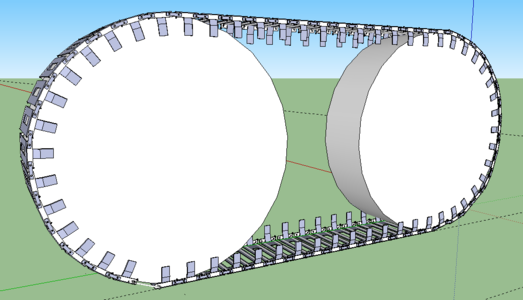

- The blue link shows one attachment point while the yellow link on the right shows the second. This design allows versatile adjustment along the entire length of the track.

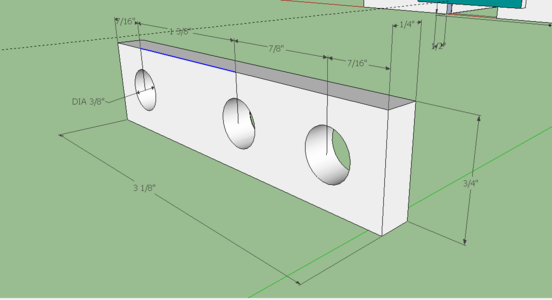

- Shows the dimensions of the link piece. I had to draw lines on the piece to be able to include the On Center dimensions of the holes.

- Width of the link piece could easily be adjusted to be thicker or thinner as needed.

- I tested the rotation and there should not be any interference with range of motion between the link and the track component.

- File:MT tracks proper.skp

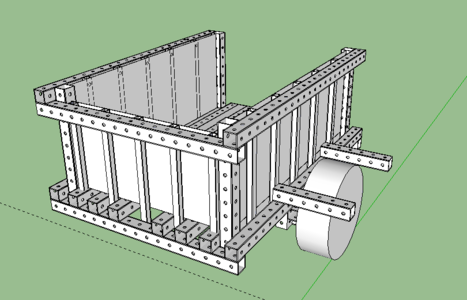

June 6, 2013: Truck (Rear)

To complete the truck's rear wheel mount and axle I used the quick attachment component from this file, File:Microtrac preliminary.skp along with the hydraulic motors.

The wheel mount was found on the wiki page, File:Wheelmount - edited 5-26-13.skp .

I am still working on adding the leaf springs to the rear. Will post those as I complete them.

- Here are some snapshots of various components from the rear truck design. (Roll over the pictures for short descriptions)

- It seems that each quick attach system will need to be custom fit for whatever wheels are being used. That is, unless we can come up with a simple design for constructing our own.

- The "skin" or cover is drawn as 1/8" sheet metal which may be excessive. I added 1" rods that are inserted into holes in the frame to add stability since there is a likely chance of someone using the cover as a step into the bed. For use as a step, 1/8" metal may be perfect.

- The angles in the cover are drawn simply because I could not figure out a way to quickly draw an arch. It is possible that if the cover was thin enough to be flexible that it could be attached to one end (the extending beam) and bent over the plate at the arch's highest point, attached and then bent to the other beam.

June 5, 2013: Truck (Rear)

-Constructed the axle with 4" square tubing. -Made the truck bed wider, slightly over 4' to allow loading of standard size plywood. -Added 2" square tubing for rigidity in sides. Hopefully they are available, or another solution will be needed. -Still have to design wheel hubs. Bent rebar would be fast, but not modular. I am thinking that I will stack two 4" tubes on top of each other which will allow clearance and then lay flat metal across. This area is not load bearing. There could be a solution far lighter and cheaper not using metal.

MicroTrac: Tracks

The tracks that I had been working on were scaled down from the tracks off of the LifeTrac which was incorrect. Here I have drawn the component with the correct sizes for the track that will fit to the MicroTrac. I was unable to figure out how to include the dimensions for the holes; they are all 3/8" in diameter. The rebar pieces are all #2 (1/4").

I tested the rotation and it appears that even if the track components were both to rotate at a 45 degree angle they will still not interfere with each other. In the case of the tracks, they should never rotate that far.

The attachment/adjustment component should still work with this design. It will have to be redrawn to fit this new model.

While thinking about the adjusting and attaching I have wondered if it would be a good idea to have two or four points for adjustment similar to snow chains on large trucks.

June 4, 2013: MicroTrac (Tracks)

Completed tracks for MicroTrac with proposed attachment/adjustment component.

Changes

Modified track with completed track component and proposed attachment/adjustment component.