Torch Table Intro

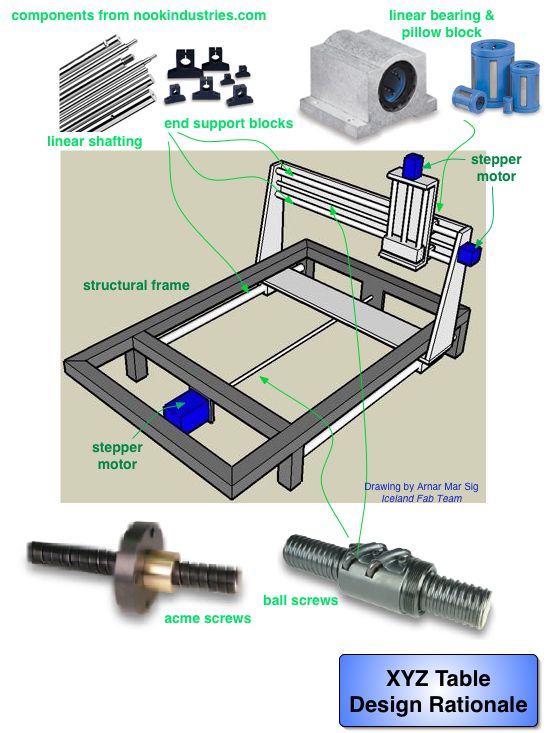

XYZ Table design

Please view our development log here. The specifications development for a robust and scaleable machine is under development here. The prototype specifications for a torch table application will be developed on this page.

The basic design follows.

Using ball screws and linear bearings appears to be the easiest method. Present research indicates that profile guide rails are twice as cheap for the accuracy required, so this will be redesigned.

Compare this to gear drive and linear rails, which appears to be more complicated in terms of drive components.

Torch Table Implementation

Specifications:

- .01 inch accuracy

- Precision acme rod

- Profile rail guides

Motors: [1]

- Nema 23 Double Stack/Double Shaft Bipolar Stepper Motor, Flats ground on each end

- 269 inch lb holding torque on main axis

- Rated Current - 2.8A/phase

- Shaft width - .25 inch

Controller:

- Direct coupling to precision acme rod

Bill of Materials for a Simple Prototype

- It appears that the Xylotex drive is applicable to large torch tables. Here is one that Xylotex told me uses their controllers and motors.

- $425 for motors and controllers

- Ball screw 5966K26 at McMaster Carr, $1.26/inch, and $25 for each ball nut - $125 per 6 foot run

- 90% mechanical efficiency compared to 30% for acme screw

- $250 for x axis if 2 screws, $125 for y axis (1 screw), $50 for z axis

- End blocks are extra

Here is a parts list:

- Compare 425 in oz motors to [269 in oz motors].

- Compare 4 axis kit, $400.

- See discussion on threaded rod vs. acme and precision acme.

- Good discussion on drive options from Solsylva

Instructables References

Search Instructables.com for CNC projects. There is a load. The people should be tapped for review. Just sign up and send authors an email.

- http://www.instructables.com/id/SDPT6W9F3HY3SLR/

- CNCZone hath lots of DIY implementations - [2]

- http://www.instructables.com/id/3-Axis-CNC-Router---60x60x5---JunkBot/

- Solsylva has plans for 3 axis tables, 2'x5' for the largest

ShopBot

Rack and Pinion Calculations

An interesting, low cost positioning system for low precision (0.01") machining (such as acetylene torch tables) consists of belt-drive rack and pinion.

Calculations:

- Typical motors have 0-1000 RPM and 200 steps

- A drive pinion of 1 inche diameter means 3 inch/200 = 15/1000 of an inch step resolution

- For a 2 inch drive wheel (recommended), this is 3/100 resolution, which is sufficient

- We need only 1/16 resolution, and we have twice that resolution with this system

Look for parts to match: