Boundary Layer Turbine

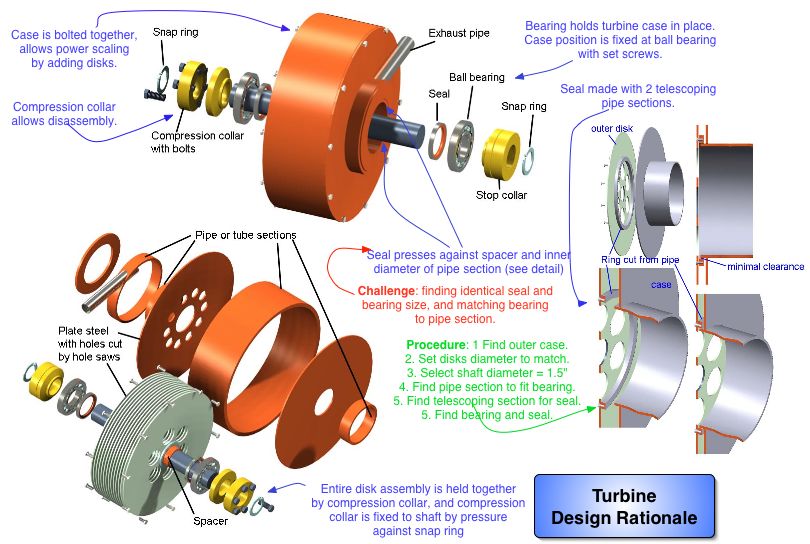

Design Rationale

Drawings by Dan Granett, Granett Engineering:

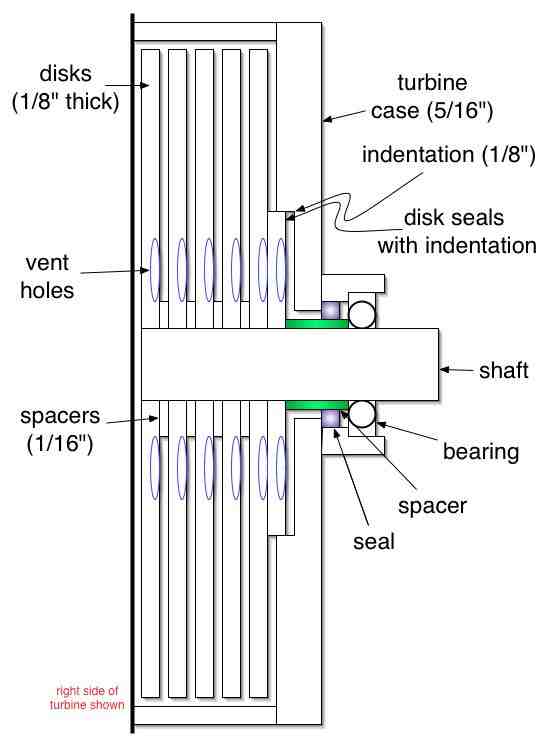

This is an external combustion engine with proven efficiencies of 25% for un-optimized models with steam (Rice, Warren, Transactions of the ASME, Journal of Engineering and Power, January 1965, pp. 28-36). A working fluid spins this turbine by means of surface friction. When the disk spacing is small (on the scale of a millimeter), energy transfer from the working fluid to the disks can be efficient. Design rationale:

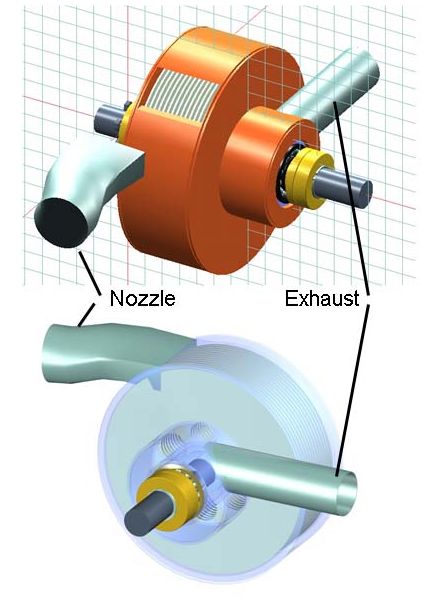

Working fluid (such as steam) enters tangentially to the disks through a nozzle:

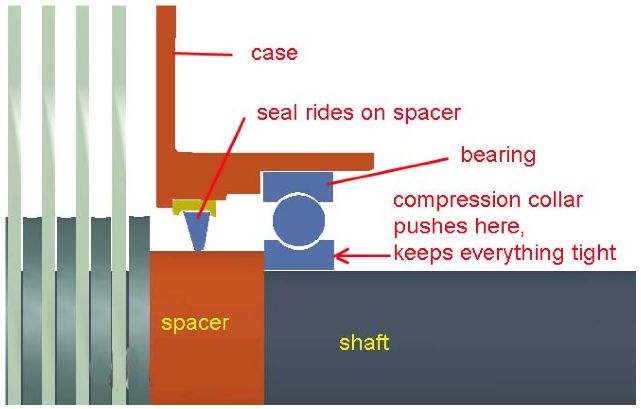

Bearings must be protected from the working fluid with a shaft seal seal:

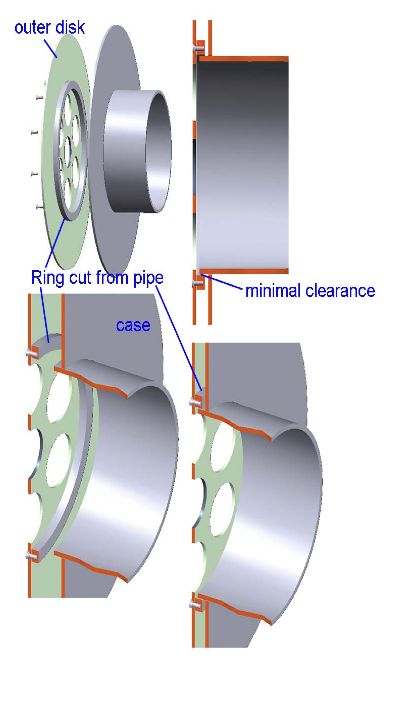

Working fluid must be prevented from escaping past the outer disks so that it can transfer its energy effectively to all the disks. To do this, we put in a ring seal:

Simplified Seal Design

The main seal (not the ballbearing seal) may be simplified as follows:

Bottom Line: Simplicity

The bounary layer turbine is the simplest design of a turbine possible, and it has a respectable efficiency of 25% without optimization. For the significantly lower simplicity and cost, it's a competitor with bladed steam turbines. Compare this to the steam turbines of modern power plants, and you can appreciate the difference:

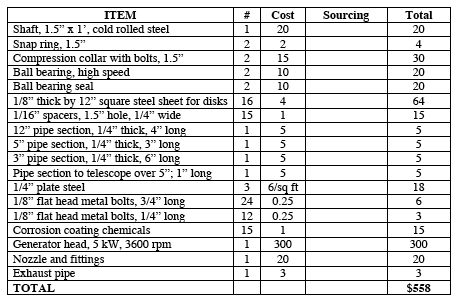

Bill of Materials: Boundary Layer Turbine

The materials cost for the boundary layer turbine, including generator head, is:

Development Log

See the Turbine Development Log.