Talk:CEB Press Development

Designed collaboratively. Factor e Farm team did the builds. Sam Rose took care of funding.

Funded by the crowd - Potential buyers, potential makers, potential entrepreneurs, people who support the vision

Open-source development

Explain different versions

Blog category on The Liberator

Development was guided by our desire to develop appropriate technology to create sustainable and equitable living, to localize production and work towards abolishing poverty.

At OSE, we believe that local manufacturing has the capacity to create a more equitable and pleasant world. We decided that a CEB press could help localize production in three ways: by schools, houses etc. to be built easily, by selling the bricks and by selling the presses.

Buildings that have been built with it

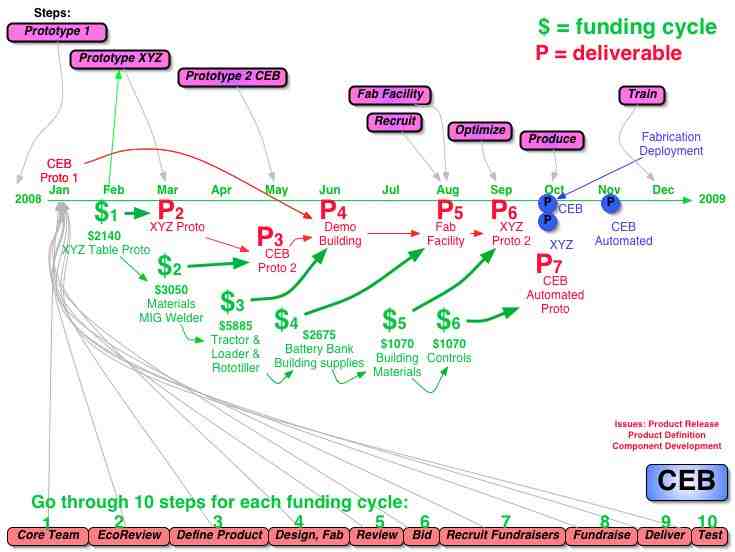

This timeline shows the development cycles on top, along with the corresponding funding cycles and deliverables in green and red. For each development cycle, we adapt a 10-step procedure, whose steps are shown at the bottom of the diagram.

Future phases for CEB evolution that we are considering beyond the present funding cycle are:

- Fully automated CEB machine, like The Liberator, where manual controls are replaced with automoatic valves and a control circuit. The only control required is turning the machine on, and from that point one simply loads soil and unloads bricks. Added material costs in this version are approximately $500.

- More powerful machines. More speed may be achieved by

- A dual machine, which features 2 compression chambers operating in parallel

- Faster machine by virtue of redesign to allow faster cycling through the steps