Industrial Robot Hydraulic Design

Illustrated Overview

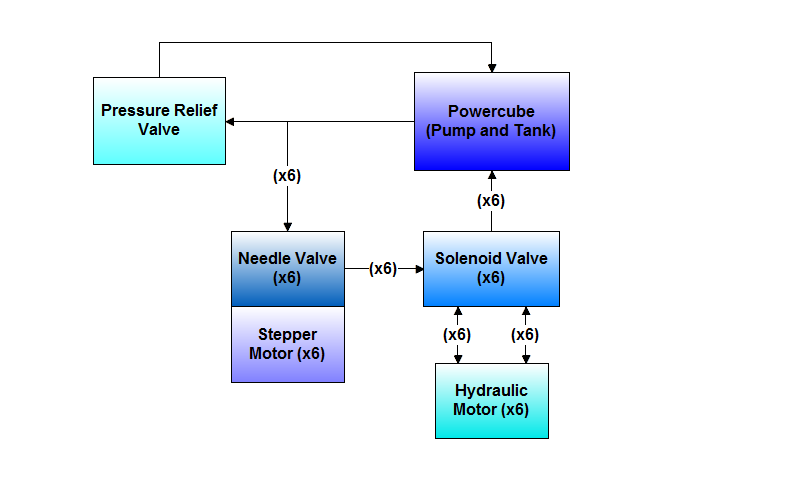

The current plan is to use a parallel hydraulic circuit (constant pressure at each joint motor, varying flow based on load force and extent of valve opening). If so, flow control is necessary (to control speed of arm movement for varying load forces) and directional control is necessary (to allow reverse arm movement). Also, a pressure relief valve back to the tank is necessary to maintain continuity of flow even while all 6 joints are stationary. Below, the arrows represent hydraulic hose connections.

Flow Control

Possibility is needle valve operated through a stepper motor which can be electronically controlled.

The flow control valve must be able to permit a flow rate from 0 to X gallons per minute (GPM) and withstand a pressure of X pounds per square inch (psi).

Directional Control

Hydraulicspenumatics on Hydraulics (including directional valves)

Possibility is 2-position, 4-way solenoid valve.

The directional control valve must be able to permit a flow rate of up to X gallons per minute (GPM) and withstand a pressure of X pounds per square inch (psi).

Pressure Relief

Wikipedia on Pressure Relief Valves

A pressure relief valve can maintain continuity of flow from the pump even while all flow control valves are closed. This improves the safety level of the hydraulic system as pressure buildup can cause failure in a hydraulic component.

Given the characteristics of the powercube used for powering the industrial robot's hydraulic system, the pressure relief valve must be able to handle a flow rate of X gallons per minute (GPM) and activate at a pressure of X pounds per square inch (psi).