Anthony Repetto/Concept Log

Concept Summaries

last updated: 13. July, 2011

Here are a few concepts OSE may find useful. I'll continue to update, and link to detailed sub-pages as I draft them. I'd love to develop simple visualizations for these ideas, and others; text is limited.

Project-Specific Considerations

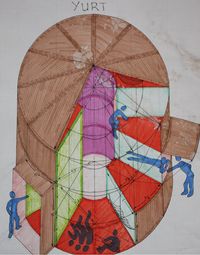

Yurt

The intention is to provide a quick start-up dwelling for new GVCS sites; same-day housing, while you wait for the CEB machine to bash bricks.

For disaster relief, slums and outliers in the developing world, and migrant/start-up labor sites: a simple, sturdy tent structure, encircling rings of 'cubbies', layered like a cake. (Picture a stack of pineapple rings.)

Rough tent dimensions: 20' (6m) wide, 12' (3 2/3m) high walls, 15' (4 1/2m) apex.

The interior cubby rings are broken into 12 radial segments; one segment is the entry way, 11 are private tents. The center is open, 6' (1 4/5m) wide, with laddering on the frame to ascend into third-tier cubbies, or to access 'attic' storage.

Each cubby is 4' (1 1/5m) tall, 1 1/2' (1/2m) wide at its interior entry, 7' (2 1/6m) long, and 5 1/4' (1 3/5m) wide along the exterior wall. Materials are: steel framing (for 34 people, plus personal supplies, or up to 100 people as a disaster shelter; mother, father, & small child per cubby - over 20,000lb (10 tonne) support necessary); exterior skirt (a single weather-resistant sheet, laid over the frame); and individual cubby tents (edges threaded with support chords, which attach to frame - at least 600lb (270kg) support necessary).

When taken apart, its compact form can be stacked in a 20' (6m) wide cylinder, which could double as a water tower, silo, or fuel tank, and, if 15' (4 1/2m) tall, the canister could hold as many as 10 such yurts. (Immediate shelter for up to 1,000 people, or 340 folks as private dwellings.) Include tools, emergency supplies, etc. for a village-in-a-box.

Trencher

There are already a wide variety of earth moving machines. Bucket wheels work quickly, but they're huge, expensive, and require expertise. Scrapers remove loose top soil, but have to haul their loads away, reducing their time-use efficiency. I wouldn't bother with an excavator. If we could build a smaller LifeTrac attachment, irrigation canals would be within reach. The primary limitations to existing designs are fuel and capital efficiency. Considering the optimal case, where you only account for the work of separating and lifting the soil, a gallon of gasoline should be able to dig a huge canal. But, existing machines breeze through fuel, and have either unacceptable lag times, requiring more operator hours, or huge up-front and maintenance costs.

I was honestly wondering, at first, if it would be more fuel and time effective to drill blast holes for ANFO, and clean up the canal faces afterwards. (At least it would be fun!) But, there might be an easier way: keep the bucket wheel's conveyor, for continuous operation, and switch the wheel out for a row of 'jackhammer' shovel teeth, which punch down into the leading face of the canal, and fold the soil onto the conveyor. The shovel face's dig cycle is shown in the sketch. (soon!) Depending upon the way it was attached to the LifeTrac, the jackhammer force on the soil surface could be driven by compressing and releasing the attachment angle; the rear wheel of the LifeTrac hoists up, transferring weight to the support wheels behind the trencher attachment, and when the hydraulics are released, the frame presses the shovel faces into the soil. (more sketches soon)

This is a new kind of earth-mover, so it violates a few OSE specifications - namely, legacy design. But, if the legacy designs are insufficient for our uses, why not make new ones? I'm not about to patent this; I'd love for Sudanese farmers to have it, to dig canals along the Sudd. Heck, if it's fuel-efficient enough, the Indian Subcontinent would go nuts for it. I'll need to get more specifics, to lay out strains and flow rates. Updates shall continue!

Chinampas & Terra Preta

Insect Farm Module

Railroad

Mini-Steam

Large steam engines require strong materials and a good bit of work. Sterling engines operate on smaller temperature gradients, at higher efficiencies (due to heat regeneration which preserves temperature gradients within the pump), but can't manage higher power applications. (Sterling engines can only handle a limited flow rate, because of low rates of heat transfer through the walls.) The goal is a small, mid-power steam engine, with a minimalist design that operates at low pressure, and 'preserves' temperature gradients, for Sterling-like efficiency. Primary use is for pairing with the Fresnel Solar modules. Ideally, the engine would induce current directly, storing power in a battery over the course of the day.

My guess is, we could make a doughnut shaped 'piston chamber' with rotating magnetic paddles, wrapped inside a solenoid. (See rough sketch. ...soon) The steam/hot gas enters the radial cavity between two paddles, causing expansion as well as rotation in one direction (the design sketch shows how paddles are linked to each other by their orbiting rings, so that expansion force drives rotation). As the paddle orbits the ring, paddles on the other side press exhaust gas through a second valve. Because the steam enters one side of the ring, and exits after making an almost complete loop, heat transfer to piston walls follows a gradient around the ring. (Steam engine piston chambers alternate between hot and cold, so each new burst of steam must warm its container, as well as expand.) As the steam speeds the orbits of the paddles, their moving magnetic fields induce current in the solenoid. Paddles could move with minimal impedance, for low-pressure steam, or the solenoid resistance could be stepped up, to extract more energy from hotter steam. Stacking modules, and routing exhaust from one into the module above it, would step-down steam temperatures and pressures; the ability to operate with lower pressures would be key for raising total efficiency. Combined Heat & Power (CHP) set-ups could tailor their capital use on the fly, depending upon how much heat was being wasted, simply by adding or removing mini-steamers from their step-down train.

With a ring of orbiting paddles, in-flows are separated from exhaust by multiple seals, reducing the risk of leaks & back-flow, and eliminating the need for troublesome bump valves. Consider, as well, that steam is transferred through a loop, with only the solenoid to impede it: excessive pressure is vented in a single orbit, by a natural increase in paddle speed. No risk of explosive pressures from compression strokes!

I've been contemplating solenoid production: Japanese yosegi (wood mosaics) are my inspiration. (More diagrams coming soon!) On the outside of a roller drum, bend sheets of copper into a spiral, pouring insulating epoxy (or similar material) between the layers just before the roller squeezes them together. Once the ring of conductive/insulating layers has solidified, plane layers off of the flat faces of the ring, to create sheets with many thin rows of copper and insulation. Curling these onto themselves, and bonding the copper, forms a single solenoid coil. Layer these coils, with more epoxy between, to create a nested 'Russian Doll' of many simple solenoids. And, with the equipment for such a technique, how cheap would it be to switch production to capacitors?