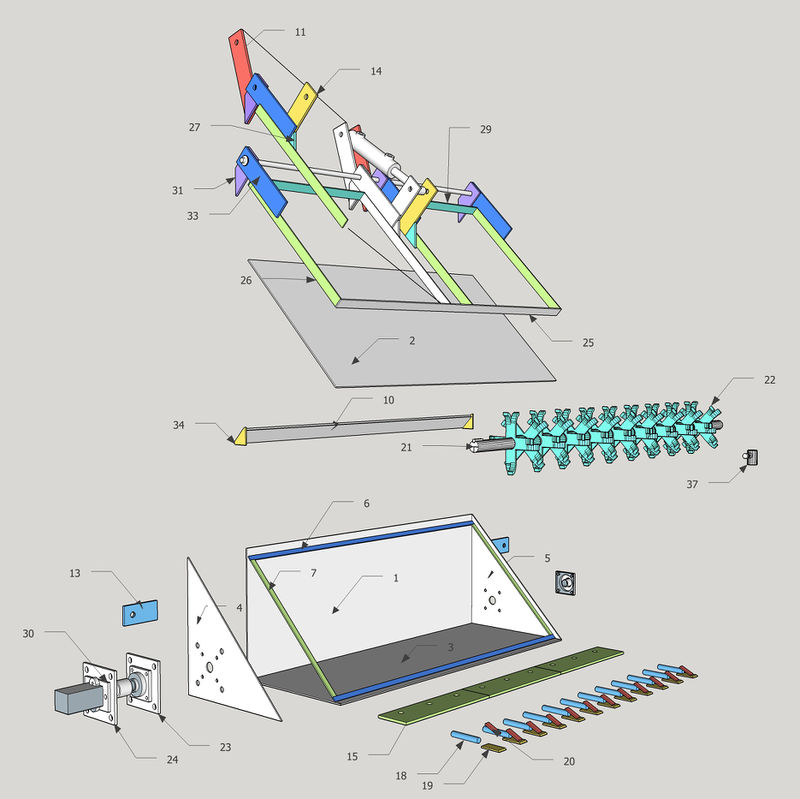

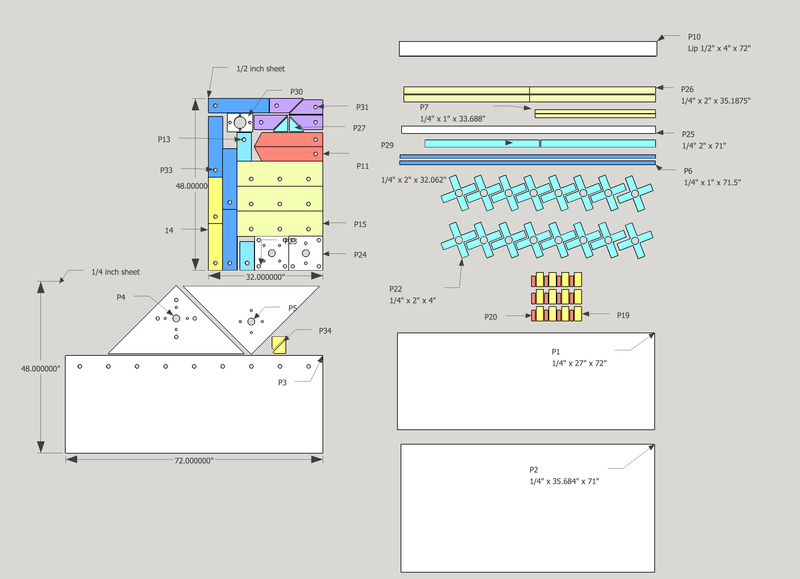

Soil Mixer - Overall Machine - Fabrication Drawings

Take P3 (Part 3) Bottom Sheet for tray and lay flat.

Tack weld backplate (P1) using a set square at a 90 degree angle on top of P3, don't finish the weld until the sidwalls have also been tacked.

Tack sidewall (P5) on the end, ensuring it matches the diagram and is on the correct side. Sidewall P4 will be placed later.

Finish the welds (on both sides of the seams?) for all seams along P1,P3,P4,P5

Lay a frame on the ground from 2 pieces of P6 and 2 pieces of P7. Do not weld yet. This is to become the seal for the mixer, and a support for the lid (P2) when closed. Check the seal dimensions with the dimensions of the lid. In the total length, the seal should have an extra 1/4" on each side from the lid. In the total height, the seal should be equal or slightly larger than the lid, but not smaller.

Take away lid P2 after verifying these dimensions, tack weld the 4 seams for the seal and ensure they don't warp (using weights?). Grind out the extra material around the welds on the top side of the seal so the lid will sit almost flush on top.

Place the seal inside the tray at a 45 degree angle. there should be 1/4" clearance where P4 will next be attached. Weld the seal in place ensuring all edges are straight.