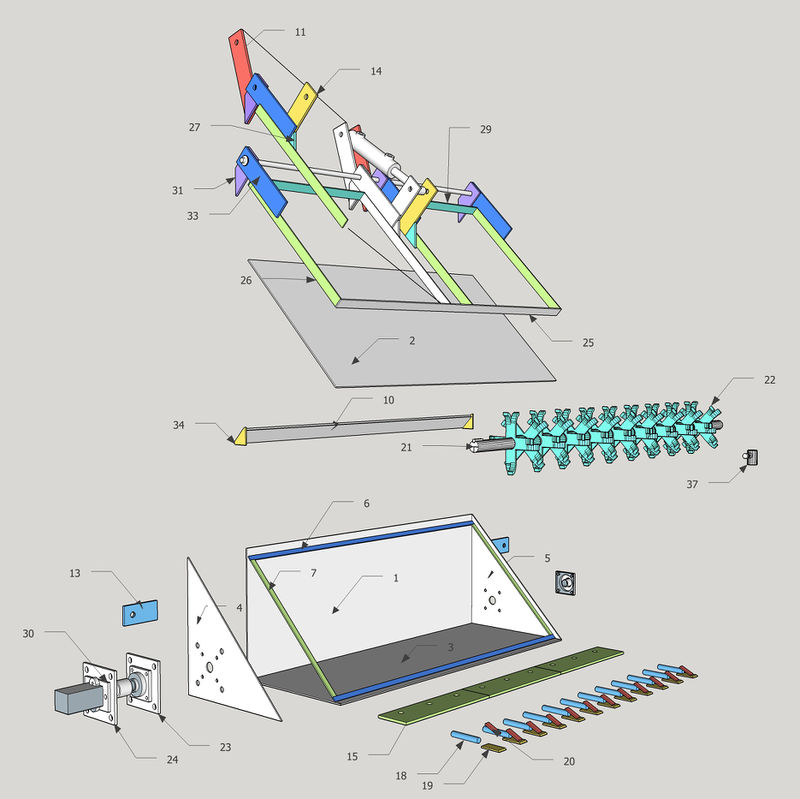

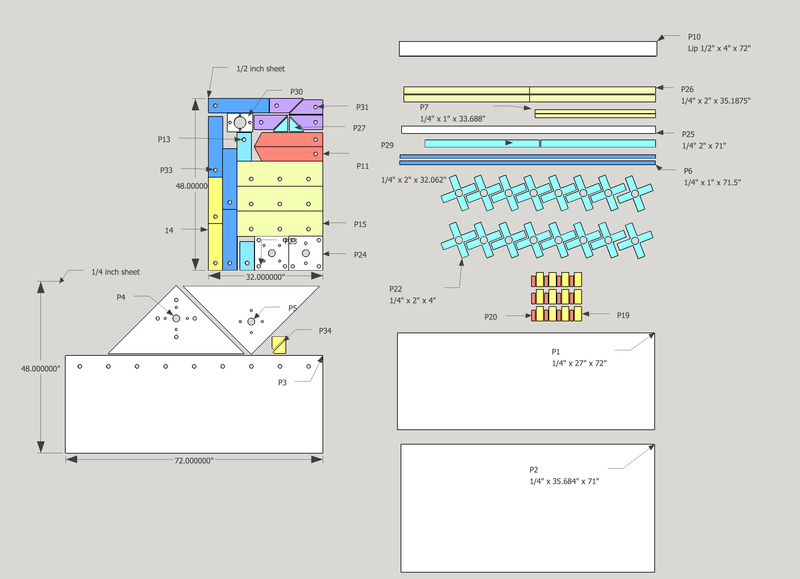

Soil Mixer - Overall Machine - Fabrication Drawings

Jump to navigation

Jump to search

- work in progress

Preparing the Bucket

- Take P3 (Part 3) Bottom Sheet for bucket and lay flat.

- Tack weld backplate (P1) using a set square at a 90 degree angle on top of P3, don't finish the weld until the sidwalls have also been tacked.

- Tack sidewall (P5) on the end, ensuring it matches the diagram and is on the correct side.

Sidewall P4 will be placed later.

- Finish the welds (on both sides of the seams?) for all seams along P1,P3,P4,P5

- Lay a frame on the ground from 2 pieces of P6 and 2 pieces of P7. Do not weld yet. This is to become the seal for the mixer, and a support for the lid (P2) when closed. Check the seal dimensions with the dimensions of the lid. In the total length, the seal should have an extra 1/4" on each side from the lid. In the total height, the seal should be equal or slightly larger than the lid, but not smaller.

- Take away lid P2 after verifying these dimensions, tack weld the 4 seams for the seal and ensure they don't warp (using weights?). Grind out the extra material around the welds on the top side of the seal so the lid will sit almost flush on top.

- Place the seal inside the bucket at a 45 degree angle. there should be 1/4" clearance where P4 will next be attached. Weld the seal in place ensuring all edges are straight.

- Weld the sidewall P4 in place on the end of the bucket

- Bolt the bearing onto Rotor Bracket P23, using 1/2" (verify?) bolts going through to P4. Ensure the nuts are on the inside of the bucket.

- Bolt the other bearing onto the outside of P5 using 1/2" bolts. Ensure the nuts are on the inside of the bucket.

- Mill a slot into the end of the driveshaft (? is a mill needed for this?) for the key.

Check that the key on the driveshaft will a fit with the coupler. Weld the key into the drive shaft.

- Thread the Driveshaft P21 through the bearings with the key on the correct side (same side for motor) of the bucket (see diagram). Place the Tynes onto the shaft as it is being threaded through.

Drive

- Take the Motor mount plate P30 and use the motor as a guide to place 2x 1/2" threaded rods into the holes of P30. Remove the motor and tack these in place in single spots. verify they are straight by placing the motor in place as a guide. remove the motor and finish tacking the bolts in place, ensure they are straight and finish the welds.

- Bolt P30 onto P24, and the motor. Attach the coupler to the motor drive shaft.

- Fit the motor and coupler to the driveshaft P21. thread the long 1" bolts through p24 towards P23 with nuts to fasten down. fasten the nuts on the other side of P24 for each bolt. For each bolt, Fasten 2 nuts on either side of P4 and p23 to sandwich them. tack the 4x large 1" nuts on the other side of P4 remove the bolts and finish the welds (?)

- Put the bolts back in place. the motor attachment to the rotor should be complete.

Teeth

- weld the teeth from P18-20. weld 4 teeth to the underside of P15, ensuring the bottoms of the teeth are flat on the ground. do this for all 3x P15 parts. these will later bolt in to the underside of P3 on the bucket.

Quick Attach Lip

- Tack 2x P11 ends onto the outside of P1, using p10 as a guide. Tack p10 in place and finish the welds along all seams on the inside and outside for these parts.

- Take a quick at attach plate from the Lifetrac and use it to ensure a fit for the bolts on P13 (x2). Bolt in place, and tack the P13 parts to P1. Unbolt and remove the QA plate now that these 2 bolt plates are welded correctly in place.

Lid

- Tack P25 at a 90 degree angle along the length of the bottom of the lid. finish welding both sides of the seams.

- Tack 2x P26 Lid Struts onto the ends of the end at a 90 degree angle. Ensure a 1/4" space for 2x P29 to fit.

- Tack 2x P29 pieces on each end of the lid at 90 degrees.

- we need to use the bolt shaft of the base of the cylinder (should be 3-5/8") as a guide for the hinge mechanism

Lay the base of the cylinder perpendicular to P25 in the centre of the lid. Provided the width of the cylinder base for the bolt is